Technology and Applications of how to cut sheet steel

Cutting sheet steel involves various technologies tailored to different thicknesses, precision needs, and production volumes. For thinner sheets (up to around 3mm), common methods include:

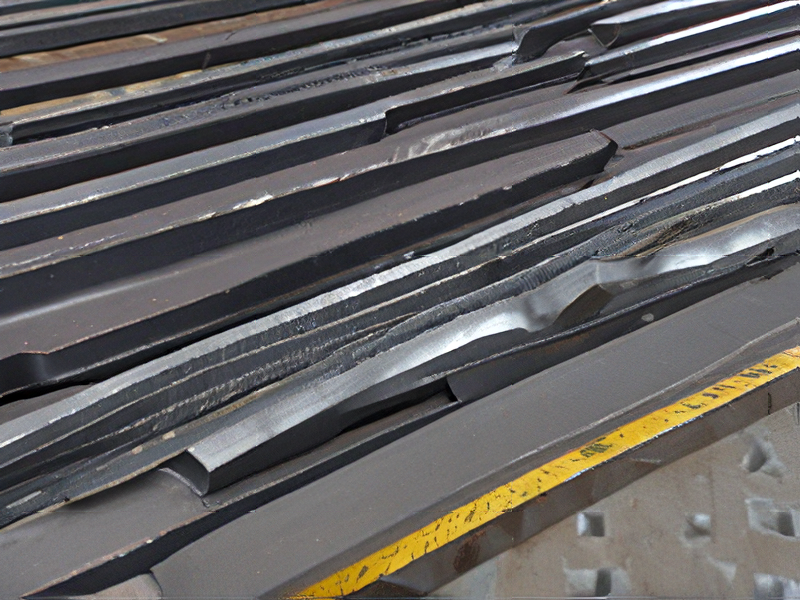

1. Shearing: Uses a shear machine with upper and lower blades to cut straight lines through the sheet. Ideal for quick, cost-effective cuts but less precise than other methods.

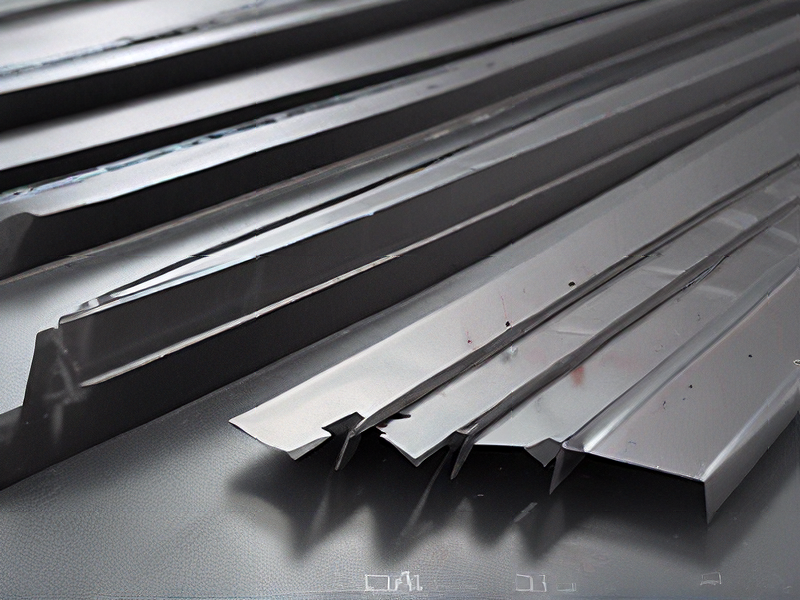

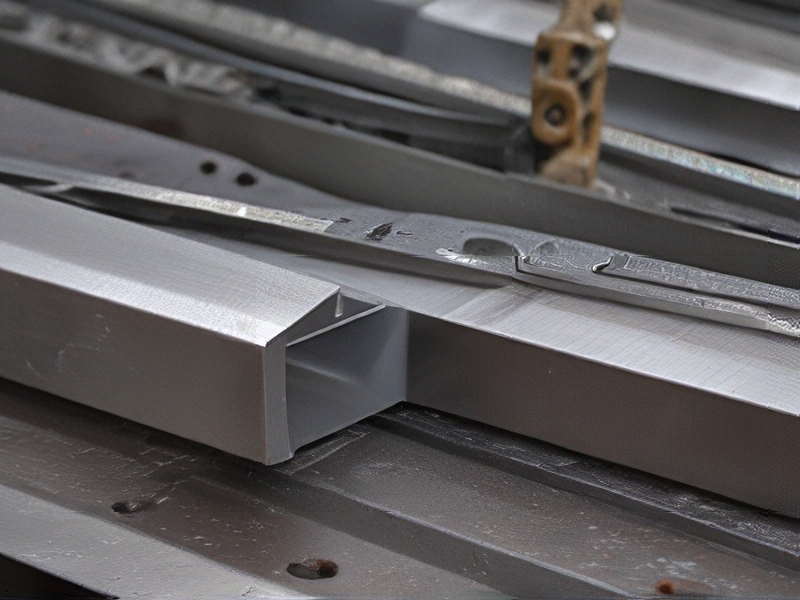

2. Laser Cutting: Employs a high-powered laser to melt, burn, or vaporize material along a programmed path. Offers high precision and can cut complex shapes quickly, suitable for both thin and thick sheets.

3. Plasma Cutting: Uses a plasma torch to ionize gas and generate an arc that melts metal and blows away molten material. Effective for thicker sheets (typically 1mm and up) and offers good cutting speed and versatility.

4. Waterjet Cutting: Utilizes a high-pressure jet of water mixed with abrasive particles to cut through sheet steel. Suitable for a wide range of materials and thicknesses, providing high precision and minimal heat-affected zones.

For thicker sheets (beyond 3mm), methods like plasma cutting and waterjet cutting are preferred due to their ability to handle higher thicknesses effectively. Each method offers unique advantages in terms of speed, precision, cost, and suitability for different production environments and sheet steel types.

Quality Testing Methods for how to cut sheet steel and how to control quality

When cutting sheet steel, quality control is crucial to ensure precise cuts and consistent quality. Here are key methods for cutting and maintaining quality:

1. Cutting Methods:

– Shearing: Utilizes shear forces to cut sheet steel cleanly. Quality is maintained by regularly inspecting and maintaining shear blades to prevent deformation and ensure accurate cuts.

– Laser Cutting: Offers precise, high-speed cutting with minimal material deformation. Quality control involves monitoring laser power, beam focus, and alignment to maintain cut accuracy and edge quality.

– Plasma Cutting: Uses ionized gas to melt and remove material. Quality is controlled by regulating gas flow, nozzle alignment, and ensuring proper electrode maintenance to prevent irregularities in cut edges.

– Waterjet Cutting: Uses high-pressure water mixed with abrasive particles to cut steel. Quality control includes monitoring pressure levels, abrasive flow rate, and nozzle wear to ensure consistent cutting depth and edge finish.

2. Quality Control Measures:

– Inspecting Cut Edges: Regularly examining cut edges for smoothness, burrs, and any signs of deformation.

– Dimensional Accuracy: Using calibrated measuring tools to verify dimensions of cut pieces against specifications.

– Surface Quality: Assessing surface finish for scratches, dents, or other imperfections that may affect final product quality.

– Material Integrity: Checking for heat-affected zones, distortion, or metallurgical changes that can occur during cutting processes.

– Process Monitoring: Implementing real-time monitoring of cutting parameters such as speed, feed rate, and tool wear to maintain consistency.

3. Documentation and Feedback:

– Recording Parameters: Keeping detailed records of cutting parameters and inspection results to identify trends and make adjustments.

– Feedback Loops: Implementing feedback loops between production and quality teams to address any issues promptly and continuously improve processes.

By integrating these methods and controls into the cutting process, manufacturers can achieve high-quality sheet steel cuts consistently, meeting stringent industry standards and customer expectations.

Tips for Procurement and Considerations when Purchasing from how to cut sheet steel

When purchasing sheet steel and considering how to cut it, here are some key tips and considerations:

1. Understand Your Requirements:

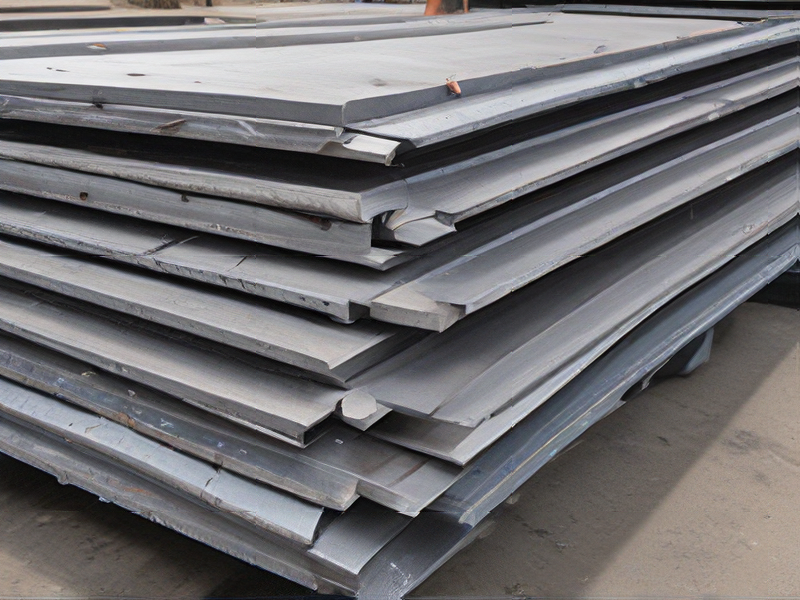

– Thickness and Grade: Ensure you know the required thickness and grade of steel for your project. Thicker sheets and higher grades often require more specialized cutting tools.

– Sheet Size: Purchase sheets in sizes that minimize waste for your intended application.

2. Supplier Selection:

– Reputation and Reliability: Choose a supplier with a strong reputation for quality and timely delivery. Check reviews and ask for references.

– Certifications: Verify that the supplier meets industry standards and holds relevant certifications.

– Price vs. Quality: Balance cost with quality. Lower prices can sometimes mean lower quality or hidden costs.

3. Material Handling:

– Storage: Proper storage is crucial to prevent rust and damage. Sheets should be kept in a dry, covered area.

– Transportation: Ensure sheets are securely transported to avoid bending or scratching.

4. Cutting Methods:

– Manual Cutting: For small-scale projects, manual tools like tin snips or hacksaws can be effective. Ensure precise measurement and marking before cutting.

– Power Tools: Angle grinders, power shears, or nibblers are suitable for more extensive cutting. These tools offer more speed and precision.

– Industrial Cutting: For large-scale or precise cuts, consider methods like laser cutting, plasma cutting, or waterjet cutting. These methods provide high precision and smooth edges but require specialized equipment and expertise.

5. Safety Considerations:

– Protective Gear: Always wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

– Work Environment: Ensure your workspace is well-ventilated and free from flammable materials, especially when using power tools or industrial cutting methods.

6. Waste Management:

– Recycling: Properly recycle scrap metal to reduce environmental impact and potentially recoup some costs.

– Efficiency: Plan cuts to maximize material usage and minimize waste.

By considering these factors, you can ensure a smooth procurement process and efficient cutting of sheet steel for your projects.

FAQs on Sourcing and Manufacturing from how to cut sheet steel in China

Certainly! Here are some FAQs regarding sourcing and manufacturing, particularly on cutting sheet steel in China:

1. How can I find reliable suppliers for sheet steel in China?

– Utilize online platforms like Alibaba or Made-in-China to search for suppliers with good ratings and reviews.

– Attend trade shows such as Canton Fair or Metal + Metallurgy China to meet potential suppliers face-to-face.

2. What are common methods for cutting sheet steel in Chinese factories?

– Laser cutting: Uses a high-powered laser beam to cut through the steel accurately and cleanly.

– Plasma cutting: Uses ionized gas to melt and remove material, suitable for thicker steel sheets.

– Waterjet cutting: Utilizes a high-pressure jet of water mixed with an abrasive substance to cut through steel.

3. How can I ensure quality control during manufacturing?

– Conduct regular inspections and audits of the production facility.

– Specify quality standards and requirements in a detailed manufacturing agreement.

– Use third-party inspection services if necessary to verify product quality.

4. What are the typical lead times for manufacturing sheet steel products in China?

– Lead times can vary based on complexity and quantity but generally range from 4 to 12 weeks.

– Ensure to clarify lead times with suppliers and account for shipping and customs clearance.

5. What are the best practices for negotiating pricing with Chinese suppliers?

– Obtain multiple quotes to compare pricing and negotiate based on volume and long-term commitments.

– Understand cost breakdowns including material costs, labor, and overheads.

– Consider factors like payment terms and currency fluctuations in negotiations.

6. What are the shipping options available for importing sheet steel from China?

– Ocean freight is the most common and cost-effective method for large quantities.

– Air freight is faster but more expensive, suitable for urgent orders or smaller quantities.

– Evaluate shipping logistics and customs procedures to avoid delays.

These FAQs provide a foundational understanding for sourcing and manufacturing sheet steel in China, covering key aspects from supplier selection to logistics management.