Choosing SourcifyChina Factory for purchasing injection molding products offers distinct advantages including competitive pricing and premium quality. The factory uses advanced machinery and adheres to stringent international standards, ensuring durable and precise molds tailored to your specifications.

Furthermore, SourcifyChina has a dedicated customer service team fluent in multiple languages, simplifying communication and reducing errors. This commitment to customer satisfaction strengthens partnerships and fosters long-term business relationships.

Additionally, SourcifyChina emphasizes fast turnaround times and efficient production schedules to meet the tight deadlines of buyers. Their streamlined logistics ensure timely delivery, reducing the risk of project delays.

The factory’s extensive experience in the injection molding industry enables it to offer valuable insights and innovative solutions. Partnering with SourcifyChina allows buyers to benefit from their expertise, driving better outcomes for their projects.

Ultimately, SourcifyChina combines cost-effectiveness, high quality, reliable communication, and prompt delivery, making it an ideal choice for global buyers seeking injection molding solutions in China.

Injection molding prices vary based on factors like material quality, mold complexity, production volume, and geographical location. Costs include mold creation, setup, and per-unit prices, influencing the overall expenditure.

– Material Quality: High-grade materials increase costs but improve durability.

– Mold Complexity: Simple molds cost less, while intricate designs raise prices.

– Production Volume: Bulk orders reduce per-unit costs through economies of scale.

– Geographical Location: Pricing differs based on regional labor and material costs.

– Mold Creation: Initial mold creation is expensive, but reusable over many cycles.

– Setup Fees: Initial setup involves costs, impacting early-stage production budgets.

– Per-Unit Prices: Vary with material and complexity; higher volumes lower individual unit costs.

– Maintenance and Upkeep: Regular mold maintenance can add to long-term expenses.

– Customization: Custom designs lead to increased costs due to unique molding requirements.

– Automation Level: Automated processes reduce labor costs but involve higher initial investments.

– Lead Times: Faster production may incur higher costs due to expedited processes.

– Energy Consumption: More energy-efficient processes can lower long-term costs.

– Material Waste: Efficient use and recycling of materials can reduce overall expenses.

– Supplier Contracts: Long-term contracts might offer discounts, impacting overall cost.

Understanding these elements helps in budgeting and reducing injection molding costs effectively.

Injection molding pricing is crucial for industries that rely on mass-produced plastic parts. Cost analysis helps businesses optimize budgets and ensure competitive pricing without sacrificing quality.

– Product Development: Assessing injection molding costs aids in predicting expenses for prototype and final product manufacturing.

– Budgeting: Accurate pricing is essential for financial planning and cost management in production.

– Supply Chain Management: Understanding the costs helps in negotiating with suppliers and setting realistic timelines.

– Quality Control: Balancing cost with material and production quality ensures durable and reliable products.

– Market Strategy: Competitive pricing can influence market positioning and consumer choices.

– Waste Minimization: Cost considerations promote efficient material use and reduce waste in the production process.

– Scalability: Proper pricing strategies enable the scalable production of items as demand increases.

– Inventory Management: Cost-effective production helps maintain optimal inventory levels without overstocking.

– Process Optimization: Analyzing costs can identify areas for improving efficiency and reducing production time.

– Customization: Costs impact the feasibility and pricing of custom parts for bespoke applications.

– Automation Integration: Automation in injection molding can affect costs but also improve production speed and consistency.

– Material Selection: Price assessments assist in choosing the most cost-effective and suitable materials for specific applications.

– Regulatory Compliance: Ensuring that cost does not compromise adherence to industry standards and regulations.

– Return on Investment: Proper cost management ensures that products remain profitable over time.

– Environmental Impact: Cost-effective approaches can also emphasize sustainable practices and reduce environmental footprints.

SourcifyChina offers competitive injection molding prices, making it an attractive choice for manufacturers. Their cost efficiency originates from extensive supplier networks and economies of scale. This allows clients to minimize production expenses without compromising on quality.

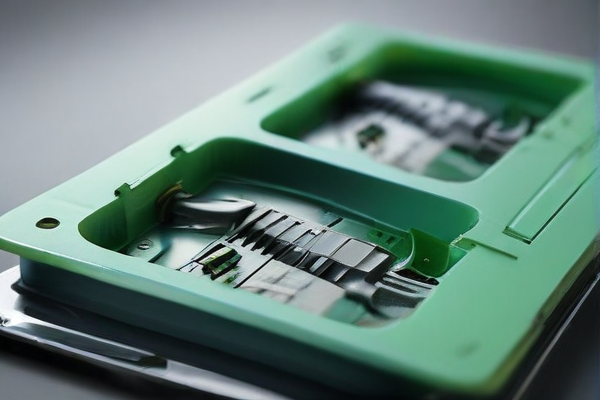

The company specializes in materials such as ABS, polypropylene, polystyrene, and polycarbonate. These polymers are renowned for their durability, flexibility, and versatility, catering to diverse industry needs. SourcifyChina ensures that its materials adhere to stringent quality standards.

Moreover, SourcifyChina leverages advanced technology in its injection molding processes. Utilizing state-of-the-art machinery ensures high precision and consistency, further enhancing the value proposition for clients. This technological edge sets SourcifyChina apart in the competitive landscape.

SourcifyChina also emphasizes sustainability in material sourcing and production. They offer eco-friendly alternatives that comply with environmental regulations. This commitment to sustainability not only benefits the planet but also attracts eco-conscious businesses.

Customer service is another cornerstone of SourcifyChina’s operation. They provide comprehensive support, from initial inquiries to post-production services. This client-centric approach ensures smooth and efficient project execution, creating long-term partnerships.

In addition to competitive pricing, SourcifyChina offers flexible payment terms to accommodate diverse financial needs. This financial flexibility enables businesses of all sizes to access high-quality injection molding services without strain.

Ultimately, SourcifyChina balances affordability, quality, and sustainability. Their comprehensive approach addresses customers’ needs holistically, making them a preferred partner for injection molding projects. By continually adapting to market demands and technological advancements, SourcifyChina ensures its clients receive the best value for their investment.

SourcifyChina is known for its competitive injection molding prices, making it an attractive choice for manufacturers and businesses worldwide. The company offers cost-efficient solutions without compromising on quality, thanks to their state-of-the-art technology and streamlined manufacturing processes.

Quality control is at the heart of SourcifyChina’s operations. Every stage, from initial design to final product, undergoes rigorous checks to ensure compliance with international standards. This meticulous approach helps in minimizing defects and maximizing customer satisfaction.

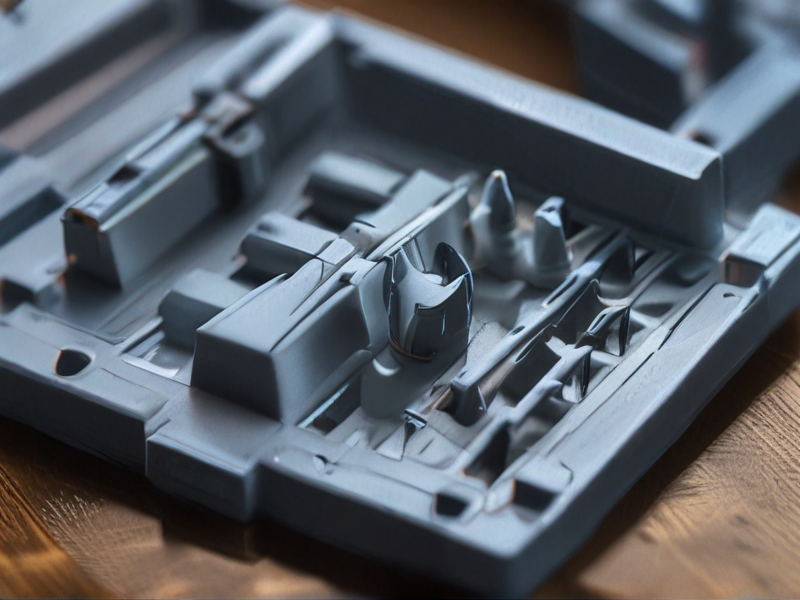

Advanced machinery used by SourcifyChina ensures precise and consistent molds each time. Skilled technicians monitor the production lines continuously to detect any inconsistencies early. This proactive approach significantly reduces waste and rework costs, ensuring timely delivery.

Inspection protocols include comprehensive tests for durability, strength, and aesthetic appeal. SourcifyChina uses high-quality raw materials to ensure that each product meets the clients’ specifications and industry requirements. These stringent checks reinforce their commitment to superior product quality.

Lastly, SourcifyChina offers flexible, customized solutions to meet specialized needs of clients. From small-batch to large-volume orders, their services are designed to be adaptive and customer-focused. Combining cost efficiency with strict quality controls, SourcifyChina promises dependable, high-quality injection molded products.

SourcifyChina provides competitive injection molding prices by leveraging their relationships with numerous Chinese manufacturers. This helps clients to significantly reduce their production costs while maintaining high-quality standards, making it an attractive option for businesses.

Their vast network of experienced suppliers enables them to offer a wide range of materials and techniques. From thermoplastics to advanced composites, SourcifyChina ensures that their clients get the best material for their specific needs, enhancing product durability and functionality.

SourcifyChina also emphasizes transparency in their pricing strategies. They provide detailed cost breakdowns for each project, allowing clients to understand where their money is going and helping them to budget more effectively. This transparency builds trust and encourages long-term cooperation.

Moreover, SourcifyChina’s project management capabilities streamline the manufacturing process. They assist clients from the initial design phase to the final production run, ensuring timely delivery and minimizing costly delays. Their expertise in managing the intricacies of injection molding projects translates to smoother operations and higher client satisfaction.

In summary, SourcifyChina stands out with its competitive pricing, diverse material options, transparent cost breakdowns, and effective project management. These capabilities make them an excellent partner for businesses looking to optimize their injection molding needs. With a strong focus on quality and efficiency, SourcifyChina is well-equipped to meet the demands of various industries, from consumer electronics to automotive parts.

Injection molding is a highly efficient and cost-effective manufacturing process for producing high volumes of plastic parts. This method offers numerous advantages, making it a favored option in various industries.

– Cost Efficiency: Economical for large production runs due to reduced labor costs and minimal material waste.

– High Production Rate: Capable of producing thousands of identical parts in a short period.

– Precision and Consistency: Excellent dimensional accuracy, ensuring parts are uniform and meet stringent specifications.

– Material Versatility: Supports a wide range of thermoplastics and thermosetting polymers.

– Reduced Post-Production Work: Smooth finish and intricate designs minimize the need for additional machining or finishing.

– Reusable Molds: Durable molds can be reused for several production cycles, further lowering costs.

– Complex Geometry Capability: Perfect for creating complex shapes and detailed features.

– Automation Potential: Can be easily automated, enhancing productivity and reducing labor costs.

Injection molding’s combination of high efficiency, precision, and versatility makes it a crucial process in the modern manufacturing landscape.

Injection molding is a widely used manufacturing process that involves high initial costs but offers significant long-term benefits in mass production.

– Material Costs: The price varies significantly based on the type of plastic resin used. Engineering plastics tend to be more expensive.

– Tooling Costs: High initial investment is required for mold creation. Complex designs and larger molds increase these costs.

– Production Volume: Costs per unit decrease as production volume increases due to economies of scale.

– Cycle Time: Faster cycle times reduce labor and machine operation costs, leading to lower overall pricing.

– Labor Costs: Automation reduces labor costs significantly, but initial setup can be expensive.

– Customization and Design: Complex geometries or bespoke designs can increase costs due to additional tooling requirements.

– Secondary Processes: Additional operations like painting, machining, or assembly also add to the costs.

– Material Utilization: Efficient use of raw materials can reduce waste and overall costs.

– Energy Consumption: High energy usage machinery impacts operational costs. Energy-efficient machines can save costs in the long run.

– Market Demand: High demand can drive up material prices, influencing overall costs.

Understanding these factors helps in optimizing the injection molding process, leading to cost-effective production and improved profitability.

SourcifyChina is a renowned service provider in injection molding, offering competitive pricing for custom products and projects. Utilizing advanced machinery and techniques, they ensure precision and efficiency in manufacturing.

Clients benefit from SourcifyChina’s cost-effective solutions, which balance quality and affordability. Their transparent pricing model allows businesses to budget effectively without compromising on product standards.

Experienced in a variety of industries, SourcifyChina caters to both small and large-scale projects. They are adept at handling complex specifications and delivering tailored solutions that meet client requirements.

Quality control is a priority at SourcifyChina. Each product undergoes rigorous testing to ensure it meets the highest standards. This commitment to excellence differentiates them from other providers.

SourcifyChina’s customer-centric approach ensures clear communication and accountability throughout the project lifecycle. They provide detailed quotes and timelines, fostering trust and reliability with their clients.

From initial concept to final delivery, SourcifyChina supports clients at every stage. Their expertise in injection molding and project management guarantees a seamless process and superior end products.

Through continuous innovation and dedication, SourcifyChina remains a top choice for businesses seeking dependable and cost-effective injection molding services for their unique needs.

SourcifyChina is an esteemed player in the injection molding industry, renowned for its competitive pricing and high-quality service offerings. With an established reputation for delivering precise, durable, and cost-effective injection molding solutions, the company caters to a vast array of industries, including automotive, electronics, medical, and consumer goods. SourcifyChina prides itself on its advanced technological capabilities and a team of skilled professionals who ensure that each project meets the stringent quality standards and specifications required by clients. Their strategic location in China enables them to leverage local manufacturing advantages, thereby reducing production costs without compromising quality. This ensures clients receive high-value services at highly competitive rates. In addition to their core injection molding services, SourcifyChina also offers comprehensive support from design to prototype development and production, establishing themselves as a one-stop solution for all injection molding needs. Their commitment to customer satisfaction, coupled with transparent pricing and punctual delivery times, reinforces their position as a reliable partner for businesses looking to optimize their manufacturing processes and reduce costs.

Injection molding, a manufacturing process for producing parts by injecting molten material into a mold, plays a crucial role in the aerospace, defense, and marine industries. Due to the high volume and precision required in these sectors, the injection molding price becomes a significant consideration. In aerospace, lightweight yet durable components are essential, and injection molding allows for the creation of intricate designs that reduce weight without compromising strength. This cost-effective method is utilized to produce everything from intricate cockpit instrument panels to aerodynamic exterior parts, optimizing both performance and cost. The durability and precision of these components ensure they meet stringent aerospace standards, while the bulk production capabilities of injection molding help keep expenses manageable.

In the defense sector, the reliability and precision of parts are paramount, and injection molding delivers on both fronts. Military equipment often requires components that can withstand extreme conditions and rigorous use. Injection molding is employed to produce robust parts for firearms, communication devices, and even protective gear, ensuring uniformity and robustness. Similarly, in marine applications, corrosion-resistant materials are essential for parts that will be submerged or exposed to harsh marine environments. Injection molding is vital for crafting complex, high-strength components such as propeller blades, underwater housings, and other marine hardware. By achieving consistent quality and reducing waste material, injection molding helps keep manufacturing costs low while maintaining top-tier performance standards. The economic efficiency of injection molding thus supports the sustainability and operational readiness of these critical industries.

Injection molding is a pivotal manufacturing process in both the automotive and electronics industries due to its cost-efficiency, ability to produce complex shapes, and scalability. In the automotive sector, injection molding enables the mass production of components ranging from small interior buttons to large exterior body panels. The precision and consistency offered by this technique are paramount in meeting the stringent safety and performance standards of automotive parts. The cost-effectiveness of injection molding is particularly beneficial in the automotive industry, where reducing material waste and labor costs can significantly affect overall production expenses. For example, high-volume parts like dashboard covers, bumpers, and lighting housings are commonly produced using injection molding, leveraging its ability to create highly detailed and durable parts at a lower per-unit cost when mass-produced.

In the electronics industry, injection molding is equally crucial, particularly for producing the intricate, high-precision components required for modern electronic devices. From smartphone casings to intricate connectors and tiny internal components, the flexibility of injection molding allows for the manufacturing of complex geometries with high precision and repeatability. The ability to use various types of plastics and polymers enhances the functionality and durability of electronic devices, while also maintaining a sleek, aesthetically pleasing design. The pricing aspect of injection molding is a significant advantage in this sector, where high production volumes can drastically reduce the cost per unit, making it ideal for producing millions of units required for consumer electronics. Many electronics manufacturers rely on this process to meet the demands of rapid technological advancements and the consumer market’s need for affordable, high-quality products.

Injection molding is a highly versatile manufacturing process used extensively in the construction industry to create durable, high-strength components at economical prices. The cost-effectiveness of the technique stems from its ability to mass-produce complex shapes with minimal material waste and reduced labor costs. For builders and contractors, the injection molding price is an appealing factor, especially when it comes to producing key infrastructural elements like plumbing fittings, electrical housings, and decorative panels. Such components, often requiring stringent compliance with industry standards, benefit from the precision and consistency that injection molding offers. As construction projects increasingly demand rapid deployment and cost-efficiency, the relatively low injection molding price makes it a financially viable option for large-scale production while maintaining high-quality outputs.

In the energy sector, injection molding plays a significant role in the fabrication of essential components for a variety of applications, from renewable energy systems to traditional power generation. With the growing focus on sustainable energy solutions, there is substantial interest in the development of low-cost, high-performance materials and components. Injection molding price is a crucial determinant for energy companies looking to optimize operational efficiency and minimize production costs. For instance, complex parts for wind turbines, solar panel mounts, and battery casings can be manufactured using this method, resulting in durable components that can withstand harsh environmental conditions. Additionally, the process’s ability to work with advanced polymers and composite materials ensures that the produced parts meet the stringent performance criteria necessary for energy applications. By leveraging the cost advantages of injection molding, energy companies can achieve a better balance between performance and affordability.

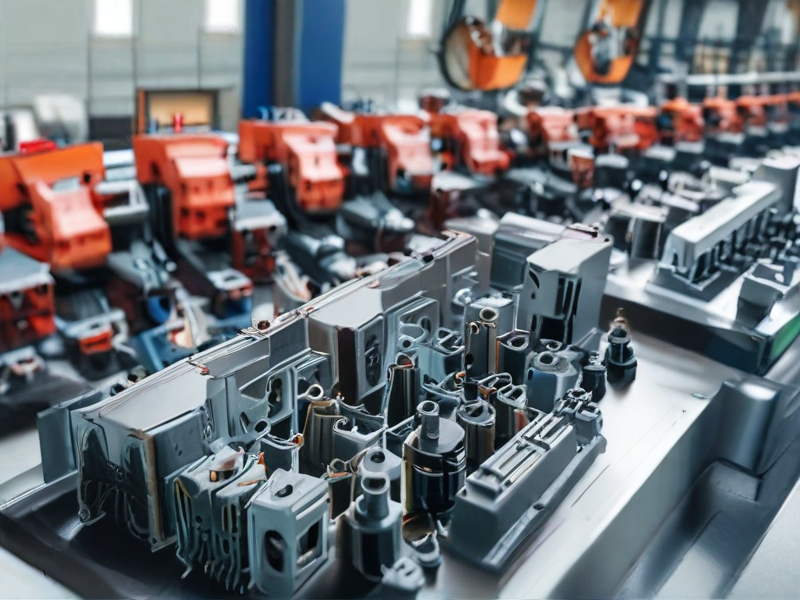

The industrial equipment industry extensively utilizes injection molding due to its ability to produce high-precision and durable parts at scale, making it a valuable manufacturing technique for creating various components. This method involves injecting molten materials, such as plastic or metals, into a mold to form intricate shapes with exceptional detail. The application of injection molding within this sector is crucial for manufacturing components like gears, housings, seals, and connectors, which are vital for the functionality and longevity of industrial machinery. The industry benefits from the cost-efficiency of this process, as it reduces material waste and often requires minimal finishing. Assessing and optimizing injection molding prices is imperative for companies to maintain competitive production costs while ensuring high quality standards.

Furthermore, the injection molding process enables the industrial equipment industry to achieve significant economies of scale. The initial investment in mold creation can be substantial, but this cost is offset by the low per-unit price during mass production. This is particularly advantageous when manufacturing standardized parts in large quantities, as it spreads the cost over many units, reducing the overall price per item. By leveraging contemporary advancements in simulation and automation, manufacturers can further drive down costs associated with trial-and-error during mold creation and enhance production speeds. Consequently, competitive injection molding prices not only help in maintaining competitive market positions but also in delivering reliable, high-performance components essential for robust industrial operations. Keeping these prices optimized allows manufacturers to meet stringent quality requirements while adhering to budget constraints, essential in an industry marked by precise engineering and durability demands.

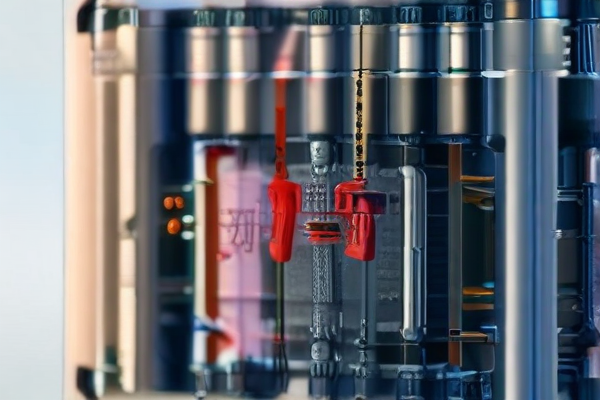

Injection molding plays a crucial role in the manufacturing of medical devices, offering a cost-effective solution for producing high-volume, precise, and complex components. The pricing of injection molding in this industry is influenced by several factors including material selection, mold complexity, and production volume. Medical-grade materials such as polycarbonate, polyethylene, and polyetheretherketone (PEEK) are often chosen for their biocompatibility and durability, which can impact the overall cost. Additionally, the initial investment in mold creation is substantial, often requiring detailed design and engineering to meet stringent regulatory standards. However, once the mold is created, the per-unit cost of producing medical device components like syringes, catheters, and implantable devices becomes relatively low, making injection molding an economical choice for large-scale production.

Furthermore, the precision of injection molding ensures consistency and reliability, which are paramount in the medical field where even minor deviations can lead to significant consequences. Automation and technological advancements in injection molding processes have further optimized production efficiency and reduced labor costs, contributing to a lower overall price. The ability to produce complex geometries with tight tolerances also allows for the innovation of new medical devices that can improve patient outcomes. By aligning with regulatory requirements and maintaining high-quality standards, injection molding not only provides an economical advantage but also ensures that medical devices are safe, effective, and ready for market. As a result, injection molding remains a popular manufacturing method for producing a wide range of medical devices, balancing cost and quality to meet the needs of the healthcare industry.

Injection molding is a widely recognized manufacturing process utilized extensively in the production of a myriad of plastic parts, from small intricate components to large structural items. One of its prime advantages is cost-efficiency, which plays a pivotal role in machining and manufacturing applications. The injection molding price encompasses various factors, such as material costs, mold design, and production volume, all of which are carefully analyzed to ensure economic feasibility. In mass production scenarios, the initial high cost of mold creation is offset by the low per-unit price achieved through high-volume manufacturing, making injection molding particularly attractive for producing large quantities of identical parts efficiently and consistently.

From a machining perspective, the introduction of advanced materials and precision mold manufacturing techniques has revolutionized the industry, driving down costs associated with injection molding. Innovations in computer-aided design and computer-aided manufacturing (CAD/CAM) have streamlined the mold-making process, reducing lead times and enhancing precision. Additionally, the use of automated systems in injection molding machines not only minimizes labor costs but also ensures uniformity and accuracy, further influencing the overall injection molding price. This amalgamation of technology and manufacturing prowess makes injection molding an indispensable method in sectors like automotive, consumer electronics, and medical devices, where cost-effectiveness and high-quality standards are imperative.

Sure! Here are some frequently asked questions (FAQ) along with answers regarding injection molding price, quality, and work from SourcifyChina factory:

1. What factors influence the cost of injection molding at SourcifyChina factory?

– The cost is influenced by several factors including mold complexity, material selection, production volume, and any additional post-processing needs. SourcifyChina provides competitive pricing based on these variables to ensure affordable solutions.

2. How does SourcifyChina ensure the quality of injection molded products?

– We use high-grade materials, advanced machinery, and employ stringent quality control processes such as ISO certifications and regular inspections to ensure that each product meets or exceeds industry standards.

3. What materials are available for injection molding at SourcifyChina?

– SourcifyChina offers a wide range of materials, including thermoplastics like ABS, polypropylene, and polycarbonate, as well as specialized resins tailored to specific requirements such as heat resistance or tensile strength.

4. What is the typical lead time for an injection molding project?

– Lead times can vary depending on the complexity and volume of the project. On average, it takes about 4-6 weeks from design approval to delivery, but expedited services are available upon request.

5. Does SourcifyChina offer design assistance for injection molding?

– Yes, SourcifyChina provides comprehensive design and engineering support, including DFM (Design for Manufacturability) analysis to optimize designs for cost-effective and efficient production.

6. Can SourcifyChina handle high-volume production runs?

– Absolutely. SourcifyChina is equipped to handle both low and high-volume production runs with equal precision and quality assurance, leveraging advanced machinery and scalable processes.

7. What kind of post-processing services does SourcifyChina offer?

– We offer an array of post-processing services including painting, coating, assembly, and packaging to ensure your products are production-ready when they leave our facility.

8. How do I get a quote for my injection molding project?

– You can get a quote by submitting your design files and specifications through our online portal or by contacting our sales team directly. A detailed quotation will be provided typically within 24-48 hours.

If you have more specific questions or need further clarification, please feel free to contact SourcifyChina directly.

When considering injection molding price manufacturing from a company like SourcifyChina factory, it’s crucial to understand and optimize several factors to get the best value:

1. Design Complexity: Simplify part designs where possible. Complex designs require more intricate molds, increasing costs.

2. Material Choice: Different plastics have varying costs. Select materials that meet your functional requirements without being overly high-end. SourcifyChina can guide material sourcing efficiently.

3. Mold Quality: Opt for durable molds that withstand long production runs. While initial costs are higher, quality molds reduce long-term expenses.

4. Quantity: Higher production volumes lower the per-unit cost. Bulk orders can significantly reduce the overall price due to spreading the mold cost over more units.

5. Production Speed: Faster cycles might increase wear and tear on molds, but slow cycles could impede cost efficiency. Balance speed and quality.

6. Manufacturing Location: Leverage SourcifyChina’s expertise in local manufacturing to minimize logistics costs and import duties.

7. Technological Advancements: Utilize factories that adopt advanced injection molding technologies to enhance precision and reduce waste.

8. Tooling Costs: Address upfront tooling costs in your budgeting. Negotiate with SourcifyChina to understand their pricing structure and any potential for discounts on large orders.

9. Secondary Processes: Factor in post-molding services like assembly, painting, or finishing. Integrating these can sometimes save costs compared to separate handling.

10. Communication: Maintain clear and consistent communication with SourcifyChina’s team. Clear specifications and regular updates help avoid costly misunderstandings.

By carefully managing these factors, you can optimize the injection molding price and achieve cost-effective manufacturing solutions from SourcifyChina’s factory, ensuring high-quality production and timely delivery.

Sure, here is a list of frequently asked questions (FAQ) with answers for sourcing injection molding prices from SourcifyChina factory:

Q: What factors influence the injection molding price at SourcifyChina factory?

A: The price is influenced by various factors including the complexity of the design, the type of material used, the size of the part, the quantity of units ordered, and any additional processes required such as painting or assembly.

Q: How can I get a quote for injection molding?

A: To get a quote, you need to provide detailed information about your project, including design files (CAD models), material specifications, quantity, and any other specific requirements. You can submit this information via SourcifyChina’s online portal or contact their sales team directly.

Q: What types of materials can SourcifyChina handle for injection molding?

A: SourcifyChina handles a wide range of materials including thermoplastics, thermosetting plastics, and various custom compounds. They can advise on the best material choice for your specific application.

Q: What is the typical lead time for injection molding projects?

A: The lead time varies depending on the complexity and scale of the project. Generally, it can range from 2 to 6 weeks. For more accurate timelines, it’s best to discuss your project details directly with SourcifyChina.

Q: Can SourcifyChina handle both small and large volume orders?

A: Yes, SourcifyChina is equipped to manage both small and large volume production runs, offering scalability according to your needs.

Q: How does SourcifyChina ensure the quality of the injection molded parts?

A: SourcifyChina follows strict quality control protocols, including in-process inspections, final inspections, and testing to ensure that all parts meet the specified criteria. They are also ISO certified, which underscores their commitment to quality.

Q: Are there any additional fees I should be aware of?

A: Additional fees may include costs for mold creation, prototyping, and any secondary processes such as surface finishing or assembly. It is advisable to ask for a detailed cost breakdown when you receive your quote.

Q: Can I request design assistance or modifications from SourcifyChina?

A: Yes, SourcifyChina offers design assistance and can help with modifications to optimize your design for the injection molding process. They provide engineering support to ensure that the final product meets your specifications.

Sourcing injection molding prices from SourcifyChina can be streamlined with these tips:

1. Prepare Detailed Specifications:

– Provide precise dimensions, materials, and design files of the parts you need molded. Clarity minimizes misunderstandings and ensures accurate quotes.

2. Request Comprehensive Quotes:

– Ask for a breakdown of costs including mold creation, production per unit, material costs, and any additional fees (e.g., setup or shipping).

3. Verify Capabilities:

– Ensure the factory can meet your quality standards and production volume. Ask about their equipment, certifications, and past projects.

4. Sample Order:

– Request a small batch before committing to larger orders. This helps assess quality and address any issues early.

5. Negotiate Terms and Conditions:

– Discuss payment terms, lead times, and quality guarantees upfront. Clear terms help prevent disputes later on.

6. Check References and Reviews:

– Look for feedback from other clients. Reliable factories will have positive reviews and provide references upon request.

7. Factory Visit:

– If possible, visit the factory to verify their operations and standards. This builds trust and provides firsthand insight.

8. Protect Intellectual Property:

– Ensure NDAs and contracts include clauses to protect your designs and data.

Utilize SourcifyChina’s platform effectively by consistently communicating and clarifying expectations. Doing so ensures a smooth process and satisfactory outcomes.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.