Technology and Applications of is aluminium a metal or nonmetal

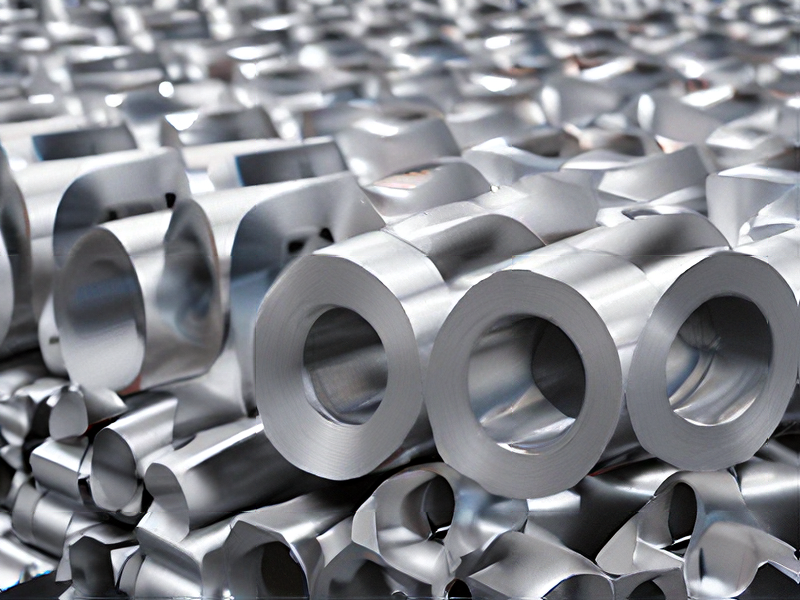

Aluminium is classified as a metal in the periodic table due to its properties. It exhibits typical metallic characteristics such as high electrical and thermal conductivity, malleability, and ductility. However, aluminium is relatively soft compared to most metals and has a low density, making it lightweight yet strong.

In terms of applications, aluminium’s unique combination of properties makes it highly versatile. It is extensively used in industries ranging from aerospace and automotive to construction and packaging. In aerospace, aluminium alloys are preferred for their strength-to-weight ratio, crucial for reducing the weight of aircraft and spacecraft while maintaining structural integrity.

In construction, aluminium’s corrosion resistance and ability to be easily shaped into various profiles make it ideal for windows, doors, and structural components. The automotive industry uses aluminium to manufacture lightweight parts that improve fuel efficiency without compromising safety.

Aluminium’s excellent reflectivity and thermal conductivity also make it indispensable in electronics and packaging industries. It is used in heat sinks for cooling electronic components and in foils for food packaging due to its barrier properties against moisture, bacteria, and light.

Overall, aluminium’s status as a metal allows it to fulfill diverse roles across multiple sectors, contributing significantly to modern technology and manufacturing processes. Its ongoing exploration in alloy development and recycling technologies continues to expand its applications and sustainability in various industries globally.

Quality Testing Methods for is aluminium a metal or nonmetal and how to control quality

Quality testing for aluminum, being a metal, primarily focuses on its chemical composition, mechanical properties, and physical characteristics.

Chemical Composition:

* Spectroscopy: Inductively coupled plasma atomic emission spectrometry (ICP-AES) or X-ray fluorescence (XRF) are used to determine the percentage of aluminum and any impurities present.

Mechanical Properties:

* Tensile Testing: Measures strength, yield point, and ductility.

* Hardness Testing: Determines resistance to indentation using methods like Brinell or Rockwell.

* Impact Testing: Assesses ability to withstand sudden shock loads.

Physical Characteristics:

* Density Testing: Verifies density against the standard value.

* Melting Point Determination: Ensures the metal melts within the expected range.

Quality Control:

* Raw Material Inspection: Incoming aluminum ingots or scraps are tested for composition and impurities.

* Process Control: Monitoring temperature, pressure, and other process variables during melting, casting, and forming.

* In-Process Inspections: Samples are taken at various stages of production for testing.

* Final Product Testing: Finished products undergo stringent quality checks before shipment.

By adhering to strict quality control measures and utilizing these testing methods, manufacturers ensure that aluminum products consistently meet the required standards.

Tips for Procurement and Considerations when Purchasing from is aluminium a metal or nonmetal

Aluminium is classified as a metal. When considering procurement of aluminium or any metal, several key factors should be taken into account:

1. Quality and Standards: Ensure the aluminium meets required quality standards (e.g., ASTM, ISO) for your specific application. Check certifications for purity and strength.

2. Suppliers: Evaluate suppliers based on reputation, reliability, and their ability to meet your volume and delivery needs. Consider their location and proximity to reduce shipping costs and lead times.

3. Cost and Pricing: Compare prices from multiple suppliers, but don’t compromise on quality. Look for opportunities to negotiate bulk discounts or long-term contracts.

4. Supply Chain Resilience: Assess the supplier’s supply chain resilience, especially in terms of sourcing raw materials and their responsiveness to market fluctuations.

5. Environmental Impact: Consider suppliers’ sustainability practices, such as recycling initiatives and energy-efficient manufacturing processes, to align with your company’s environmental goals.

6. Technical Support: Ensure the supplier offers adequate technical support and after-sales service, especially if you require custom alloys or specifications.

7. Logistics and Delivery: Evaluate logistics capabilities to ensure timely delivery and packaging that protects against damage during transit.

8. Contractual Terms: Review payment terms, warranties, and liability clauses carefully to mitigate risks and ensure clarity in case of disputes.

9. Regulatory Compliance: Ensure the supplier adheres to local and international regulations regarding aluminium production and transportation.

10. Feedback and Reviews: Seek feedback from other customers or industry peers regarding their experiences with the supplier.

By considering these factors, you can make informed decisions when procuring aluminium or any metal, ensuring quality, reliability, and cost-effectiveness aligned with your operational needs.

FAQs on Sourcing and Manufacturing from is aluminium a metal or nonmetal in China

FAQs on Sourcing and Manufacturing Aluminium in China

Q1: Is aluminium a metal or nonmetal?

A1: Aluminium is classified as a metal. It is a lightweight, silvery-white metallic element known for its malleability, durability, and resistance to corrosion.

Q2: Why source aluminium from China?

A2: China is one of the largest producers of aluminium in the world. Its extensive supply chain, competitive pricing, and advanced manufacturing technology make it an attractive option for sourcing aluminium.

Q3: What are the different aluminium products available?

A3: China manufactures a wide range of aluminium products, including sheets, plates, extrusions, and alloys. These products are used in various industries, such as automotive, aerospace, construction, and consumer goods.

Q4: How do I ensure quality in aluminium sourcing?

A4: To ensure quality, conduct thorough supplier assessments, request certifications (like ISO 9001), and consider third-party inspections during production. Establishing clear specifications and conducting sample tests before bulk orders can also help mitigate risks.

Q5: What are the common manufacturing processes for aluminium in China?

A5: Common processes include extrusion, casting, rolling, and forging. These methods are utilized depending on the specific product requirements and applications.

Q6: What are the environmental regulations related to aluminium manufacturing in China?

A6: China has been implementing stricter environmental regulations in response to pollution concerns. It’s essential to partner with manufacturers who comply with these regulations to ensure sustainable practices.

Q7: How can I navigate tariffs and trade policies when sourcing from China?

A7: Stay informed about current trade policies and tariffs that may affect aluminium imports. Consulting a trade expert or using a sourcing agent can help manage these complexities effectively.