Technology and Applications of is steel magnet

Technology and Applications of Magnetic Steel

Is Steel Magnetic?

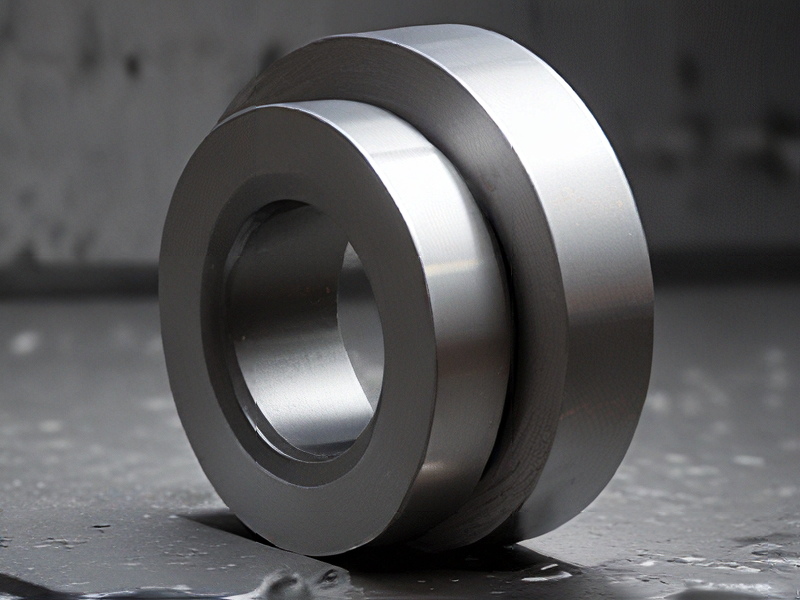

Steel is an alloy primarily composed of iron, which inherently has magnetic properties. However, the magnetism of steel depends on its composition and structure. Most steels are magnetic, but stainless steels, containing high amounts of chromium and nickel, can be non-magnetic due to their crystal structure.

Technology Behind Magnetic Steel:

1. Material Composition: Steel’s magnetic properties arise from its iron content. When alloyed with other elements, the magnetic properties can be enhanced or diminished. For instance, adding nickel can reduce magnetism.

2. Heat Treatment: The magnetic properties of steel can be manipulated through heat treatment processes, which alter the internal structure of the metal.

3. Cold Working: Deforming steel at low temperatures can increase its magnetism by realigning its crystal structure.

Applications of Magnetic Steel:

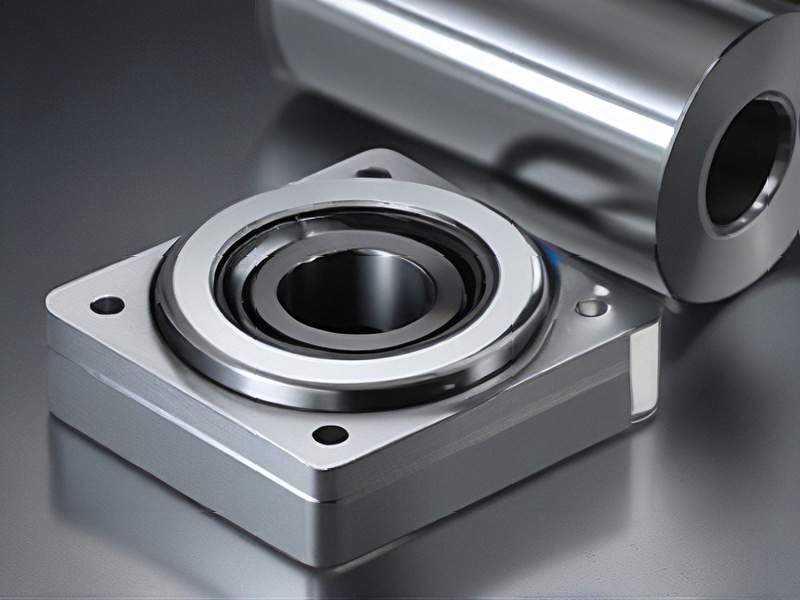

1. Electric Motors and Generators: Magnetic steel is crucial in the construction of rotors and stators, where it helps in converting electrical energy to mechanical energy and vice versa.

2. Transformers: Steel’s magnetic properties enable efficient magnetic flux conduction, making it essential in transformer cores.

3. Magnetic Storage Media: Steel components are used in hard drives and other magnetic storage devices to record and store data.

4. Sensors and Actuators: Magnetic steel is used in various sensors and actuators, where magnetic properties are utilized for detection and movement.

5. Magnetic Separators: In recycling and material processing industries, magnetic steel helps in separating ferrous materials from non-ferrous materials.

In conclusion, the magnetism of steel is a pivotal property that finds numerous technological applications. The ability to control and utilize this magnetism has led to advancements in various fields, from energy generation to data storage.

Quality Testing Methods for is steel magnet and how to control quality

Quality Testing Methods for Steel Magnetism

1. Magnetic Permeability Testing: Measures the ability of steel to become magnetized. Tools like a permeability meter can be used to ensure the steel meets required standards.

2. Magnetization Testing: Involves magnetizing the steel and using a Gauss meter to measure the magnetic field strength. This helps determine the steel’s magnetic properties.

3. Coercivity Testing: Assesses the steel’s resistance to becoming demagnetized. High-coercivity steel retains magnetism longer and is tested using a coercivity meter.

4. Hysteresis Loop Analysis: Involves plotting the magnetization and demagnetization cycle to study the steel’s magnetic behavior, using a hysteresis graph.

5. Eddy Current Testing: Uses electromagnetic induction to detect surface and sub-surface flaws in the steel. It’s a non-destructive method to ensure the material’s integrity.

6. Visual Inspection: Checks for surface defects that could affect magnetic properties, such as cracks or inclusions.

Quality Control Methods

1. Standardization: Ensures all steel batches conform to established magnetic property standards.

2. Calibration: Regular calibration of testing equipment to maintain accuracy and reliability.

3. Sampling: Randomly selecting samples from production batches for testing to detect any anomalies.

4. Documentation: Keeping detailed records of test results and procedures to track performance and identify areas for improvement.

5. Training: Regular training for personnel on testing procedures and equipment handling to minimize errors.

6. Automation: Using automated systems for testing and data collection to enhance precision and reduce human error.

7. Regular Audits: Conducting periodic internal and external audits to ensure compliance with quality standards and identify potential areas for improvement.

By implementing these testing and control methods, the quality of steel magnetism can be effectively monitored and maintained.

Tips for Procurement and Considerations when Purchasing from is steel magnet

When procuring steel from suppliers, several key factors must be considered to ensure you make informed decisions and maintain quality standards. Here are essential tips and considerations:

1. Supplier Reputation: Choose suppliers with a solid track record for quality, reliability, and customer service. Look for certifications like ISO, which indicate adherence to international standards.

2. Quality Assurance: Ensure the steel meets industry standards and specifications. Request certifications of quality and conduct periodic inspections and tests on the materials received.

3. Pricing and Payment Terms: Compare prices from multiple suppliers but be wary of prices that seem too low, as they may indicate inferior quality. Negotiate favorable payment terms that allow for flexibility and cash flow management.

4. Delivery and Lead Times: Evaluate the supplier’s delivery capabilities. Consistent, on-time delivery is crucial to avoid production delays. Consider suppliers with efficient logistics and proximity to your location.

5. Sustainability and Ethics: Choose suppliers committed to sustainable practices and ethical sourcing. This not only enhances your corporate responsibility but can also improve your brand image.

6. Technical Support and Services: A good supplier should offer technical support, including advice on steel grades, fabrication methods, and application suitability. They should also provide after-sales support.

7. Magnetism in Steel: Steel’s magnetic properties vary based on its composition. Most carbon steels are magnetic, while stainless steels can be either magnetic or non-magnetic depending on their microstructure (austenitic grades like 304 and 316 are generally non-magnetic).

8. Customization and Flexibility: Assess the supplier’s ability to provide customized solutions tailored to your specific needs. Flexibility in terms of order sizes and specifications is advantageous.

9. Regulatory Compliance: Ensure the steel complies with local and international regulations, including safety, environmental, and health standards.

By carefully evaluating these factors, you can secure high-quality steel that meets your operational requirements and contributes to the overall success of your projects.

FAQs on Sourcing and Manufacturing from is steel magnet in China

FAQs on Sourcing and Manufacturing from IS Steel Magnet in China

1. What is IS Steel Magnet?

IS Steel Magnet is a prominent supplier and manufacturer of steel products in China, offering a wide range of steel types and grades for various industrial applications.

2. What types of steel products are available?

IS Steel Magnet provides a variety of steel products including hot-rolled, cold-rolled, galvanized, and stainless steel sheets, coils, and plates. They also offer customized steel components based on client specifications.

3. How do I start the sourcing process?

To begin sourcing from IS Steel Magnet, contact their sales team via their website or email. Provide details about your requirements, including the type and quantity of steel needed, and they will guide you through the quotation and ordering process.

4. What are the payment terms?

Payment terms typically include options such as Telegraphic Transfer (T/T), Letter of Credit (L/C), and other secure payment methods. Specific terms can be negotiated based on the order size and client relationship.

5. Can IS Steel Magnet handle large volume orders?

Yes, IS Steel Magnet is equipped to handle large volume orders due to their extensive manufacturing capabilities and supply chain network.

6. What quality control measures are in place?

IS Steel Magnet implements stringent quality control measures throughout the manufacturing process, including raw material inspection, production monitoring, and final product testing to ensure compliance with international standards.

7. Are there any certifications available?

IS Steel Magnet holds various certifications such as ISO 9001 for quality management, ensuring that their products meet international quality standards.

8. How is shipping handled?

Shipping is managed by IS Steel Magnet’s logistics team, which can arrange for sea, air, or land transport. They offer flexible shipping options to meet customer needs and ensure timely delivery.

9. Can I visit the manufacturing facilities?

Yes, clients are welcome to visit IS Steel Magnet’s manufacturing facilities to inspect the production process and meet the team. Arrangements can be made through their customer service department.

10. What support is available post-purchase?

IS Steel Magnet provides comprehensive after-sales support, including technical assistance, product replacement, and customer service to address any issues that may arise.

For more detailed information, visit the IS Steel Magnet website or contact their customer service team directly.