Technology and Applications of is zinc metal magnetic

Zinc metal, in its pure form, is not magnetic. It is classified as a diamagnetic material, meaning it has a very weak and negative susceptibility to magnetic fields. When exposed to a magnetic field, zinc will create an induced magnetic field in the opposite direction, resulting in a repulsive effect. This property is typical of diamagnetic materials, which generally have paired electrons that produce no net magnetic moment.

Applications of Zinc:

1. Galvanization:

Zinc’s primary application is in galvanization, where it is used to coat iron and steel to prevent rusting. The zinc layer acts as a protective barrier, and even if scratched, it offers sacrificial protection, corroding first before the underlying metal.

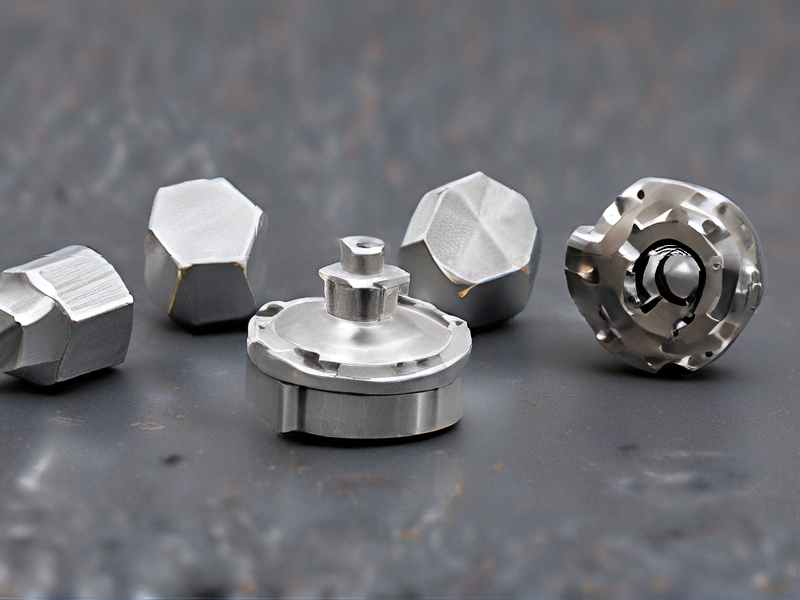

2. Alloys:

Zinc is a key component in various alloys. Brass, an alloy of copper and zinc, is used in musical instruments, plumbing, and hardware due to its acoustic properties and resistance to corrosion. Zinc-aluminum alloys (ZA alloys) are used in die casting, which finds applications in automotive, electrical, and hardware industries due to their strength and durability.

3. Batteries:

Zinc is used in batteries, such as zinc-carbon and zinc-air batteries. These batteries are commonly used in flashlights, remote controls, hearing aids, and other portable electronic devices due to their low cost and reliable performance.

4. Chemical Industry:

Zinc is used in the production of various chemicals, including zinc oxide, which is used in rubber manufacturing, pharmaceuticals, cosmetics, and as a UV protector in sunscreens. Zinc sulfate is used in agriculture as a dietary supplement for animal feed and fertilizers.

5. Construction:

Zinc sheets and plates are used in the construction industry for roofing, cladding, and rainwater systems. Zinc’s durability, corrosion resistance, and aesthetic appeal make it a popular choice for architectural applications.

Despite its lack of magnetic properties, zinc’s versatility in industrial applications highlights its importance in modern technology and manufacturing.

Quality Testing Methods for is zinc metal magnetic and how to control quality

Determining whether zinc metal is magnetic involves testing its magnetic susceptibility. Zinc itself is not magnetic in its pure form due to its non-ferromagnetic properties. Quality control methods for zinc metal typically involve:

1. Visual Inspection: Check for surface defects, discoloration, or irregularities that could indicate impurities or manufacturing issues.

2. Chemical Composition Analysis: Use techniques like X-ray fluorescence (XRF) or atomic absorption spectroscopy (AAS) to verify the elemental composition and ensure it meets specified purity levels.

3. Physical Properties Testing: Measure density, hardness, and tensile strength to confirm adherence to required specifications.

4. Corrosion Resistance Testing: Conduct tests such as salt spray testing or humidity exposure to assess resistance to corrosion, a critical factor for zinc products.

5. Dimensional Inspection: Ensure dimensional accuracy through measurements against technical drawings or specifications.

To maintain quality control:

– Establish Standards: Define clear quality standards and specifications for zinc metal based on industry requirements.

– Regular Testing: Implement regular sampling and testing procedures throughout production to monitor quality consistency.

– Supplier Evaluation: Evaluate and select suppliers based on their ability to consistently meet quality standards and provide certified materials.

– Process Controls: Implement process controls such as temperature monitoring during smelting or casting to minimize variability.

By employing these methods and controls, manufacturers can ensure that their zinc metal products meet quality expectations regarding magnetic properties and overall performance.

Tips for Procurement and Considerations when Purchasing from is zinc metal magnetic

When considering procurement of zinc metal, particularly in applications where magnetic properties are a concern, here are some key tips and considerations:

1. Material Specifications: Ensure the zinc metal you are procuring meets the required specifications, including its magnetic properties if relevant. Zinc itself is not magnetic in its pure form, but impurities or alloying elements can affect this property. Verify with the supplier or manufacturer about the specific composition and magnetic characteristics of the zinc.

2. Supplier Reliability: Choose a reputable supplier with a track record of providing high-quality metals. Check for certifications and reviews that attest to their reliability and product consistency. This is crucial to avoid issues with material quality and compliance.

3. Cost Considerations: Compare prices from different suppliers while keeping quality and reliability in mind. Opting for the cheapest option might compromise on material purity or supplier reliability, which can lead to increased costs in the long run due to defects or delays.

4. Application Requirements: Understand the exact requirements of your application regarding magnetic properties. If magnetic susceptibility is critical, consider requesting test certificates or conducting independent tests to validate the material’s suitability.

5. Delivery and Lead Times: Ensure the supplier can meet your delivery schedule and lead time requirements. Delays in procurement can disrupt production schedules and incur additional costs.

6. Environmental and Regulatory Compliance: Verify that the supplier adheres to environmental standards and regulatory requirements relevant to the production and distribution of zinc metal. This ensures ethical sourcing and compliance with local laws.

7. Packaging and Handling: Consider how the zinc metal will be packaged and transported to prevent contamination or damage during transit. Adequate packaging also minimizes the risk of material loss or degradation.

8. Long-Term Supplier Relationships: Building a long-term relationship with a reliable supplier can provide benefits such as consistent quality, preferential pricing, and priority access during shortages.

By carefully considering these factors and conducting thorough research, you can make informed decisions when procuring zinc metal, ensuring it meets both your technical requirements and business needs effectively.

FAQs on Sourcing and Manufacturing from is zinc metal magnetic in China

FAQs on Sourcing and Manufacturing Zinc Metal in China

1. Is Zinc Metal Magnetic?

Zinc is not magnetic. It is a diamagnetic metal, which means it does not generate a magnetic field on its own and is slightly repelled by a magnetic field.

2. Why Source Zinc Metal from China?

China is one of the largest producers of zinc in the world. The country offers competitive prices, a wide range of suppliers, and robust manufacturing infrastructure, making it a preferred destination for sourcing zinc metal.

3. What Are the Main Uses of Zinc?

Zinc is primarily used for galvanizing iron and steel to prevent rusting. It is also used in alloys (such as brass), batteries, and die-casting.

4. How to Identify a Reliable Zinc Supplier in China?

To find a reliable supplier:

– Verify the company’s credentials and certifications.

– Request samples and inspect quality.

– Check customer reviews and ratings.

– Conduct factory audits if possible.

5. What Are the Key Considerations in Manufacturing with Zinc?

When manufacturing with zinc, consider:

– Purity and grade of the zinc.

– The type of alloy or application.

– Cost and supply stability.

– Compliance with international standards.

6. What Are the Common Challenges in Sourcing Zinc from China?

Challenges include:

– Quality control issues.

– Communication barriers.

– Long shipping times and costs.

– Regulatory and compliance issues.

7. How to Ensure Quality Control?

Ensure quality by:

– Establishing clear specifications and quality standards.

– Conducting regular inspections and audits.

– Using third-party quality control services.

8. What Is the Typical Lead Time for Zinc Supply from China?

Lead times can vary but generally range from 2 to 6 weeks, depending on the order size and specific requirements.

9. Are There Any Import Duties or Taxes?

Import duties and taxes depend on the destination country’s regulations. It’s important to check the latest tariff schedules and trade agreements.

10. How to Manage Logistics and Shipping?

Work with experienced logistics providers, ensure proper packaging, and choose the right shipping method (air, sea, or rail) based on cost and urgency.