Technology and Applications of laser cut metal

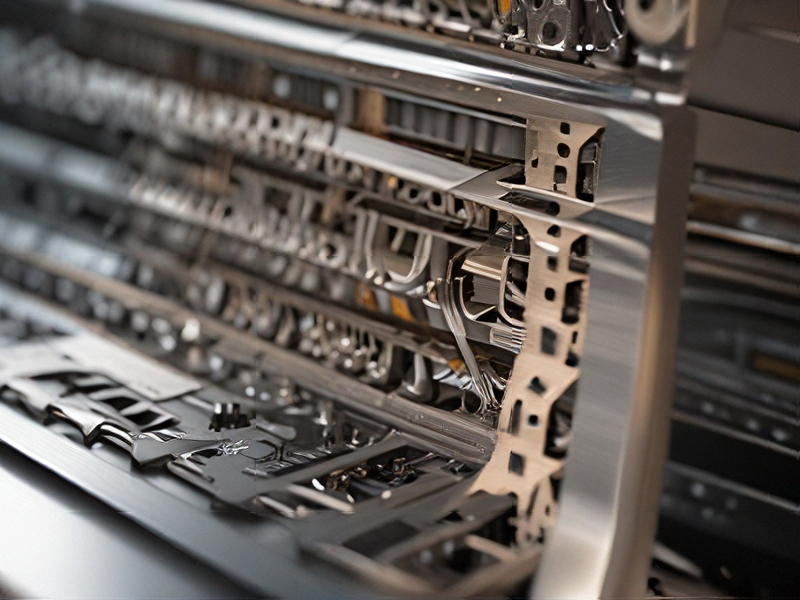

Laser cutting technology revolutionizes metal fabrication by offering precision, speed, and versatility. Using a focused laser beam, typically CO2 or fiber lasers, it vaporizes or melts metal with intense heat, guided by CNC (Computer Numerical Control) systems. This method excels in intricate designs and high-volume production, cutting various metals including steel, aluminum, and titanium with minimal material wastage.

Applications span diverse industries:

1. Automotive: Laser-cut parts ensure precise fit and durability in vehicle assembly, from chassis components to intricate interior designs.

2. Aerospace: Critical for lightweighting components, enhancing fuel efficiency, and meeting stringent safety standards with precise cuts in alloys like titanium.

3. Architecture: Enables complex facade designs, decorative panels, and structural components with high aesthetic appeal and durability.

4. Electronics: Microscopic precision aids in manufacturing circuit boards, ensuring reliable conductivity and compact designs.

5. Medical: Used in surgical tools, implants, and equipment manufacturing for sterile, precise components crucial for patient safety.

6. Art and Design: Artists and designers utilize laser-cut metal for sculptures, jewelry, and customized decorative elements due to its ability to achieve intricate details.

Advantages include speed, automation reducing labor costs, and the ability to produce highly complex shapes without tooling changes. Challenges include initial setup costs and limitations on material thicknesses in some cases. As technology advances, laser cutting continues to expand its capabilities, driving innovation across various sectors.

Quality Testing Methods for laser cut metal and how to control quality

Quality testing methods for laser-cut metal typically focus on several key aspects to ensure precision and consistency:

1. Dimensional Accuracy: Use calipers, micrometers, or coordinate measuring machines (CMMs) to measure dimensions against design specifications. This ensures parts are cut to the correct size.

2. Edge Quality: Inspect the cut edges for smoothness, burrs, and dross (residual material). Visual inspection and tactile methods can determine if the edges meet quality standards.

3. Geometric Tolerances: Employ optical comparators or CMMs to verify angles, hole diameters, and other geometric features against tolerance limits specified in engineering drawings.

4. Material Integrity: Use non-destructive testing (NDT) methods like dye penetrant testing or ultrasonic testing to check for cracks, voids, or other defects that could affect structural integrity.

5. Surface Finish: Measure surface roughness using profilometers or surface roughness testers to ensure the finish meets required specifications.

To control quality:

– Process Monitoring: Regularly monitor laser parameters (power, speed, focus) and machine condition to maintain consistency.

– Operator Training: Train operators in proper machine setup, maintenance, and quality inspection techniques.

– Quality Assurance Plans: Develop and follow comprehensive quality control plans that outline inspection points, testing methods, and acceptance criteria.

– Feedback Loop: Establish a feedback mechanism where any deviations from quality standards trigger immediate corrective actions.

By implementing these testing methods and quality control measures, manufacturers can ensure laser-cut metal parts meet customer requirements and industry standards consistently.

Tips for Procurement and Considerations when Purchasing from laser cut metal

When procuring laser-cut metal, several key considerations ensure you get the best value and quality for your investment:

1. Material Selection: Different metals have distinct properties. Consider the end use of the product—stainless steel for corrosion resistance, aluminum for lightweight applications, or carbon steel for cost-effectiveness and strength.

2. Quality Standards: Verify that the supplier adheres to relevant industry standards (e.g., ISO certifications). High-quality laser cutting ensures precise dimensions and clean edges, reducing the need for additional finishing.

3. Supplier Capabilities: Assess the supplier’s equipment and technology. Modern, well-maintained laser cutters provide better accuracy and efficiency. Ensure the supplier can handle the required thickness and complexity of your designs.

4. Experience and Expertise: Choose a supplier with a proven track record in laser cutting. Experienced suppliers can offer valuable insights into design optimizations and potential cost-saving measures.

5. Design Specifications: Provide clear, detailed design files (preferably in CAD format) to avoid misunderstandings. Confirm that the supplier can meet your specific requirements regarding tolerances, cut quality, and finishing.

6. Volume and Lead Times: Discuss the expected order volumes and lead times upfront. Ensure the supplier can handle your production schedule, especially if you have high-volume or time-sensitive needs.

7. Cost Factors: Beyond the per-unit price, consider other costs like setup fees, shipping, and potential post-processing needs. Request detailed quotes to compare different suppliers effectively.

8. Prototyping and Testing: Before committing to large orders, consider requesting prototypes or samples. This helps verify the supplier’s quality and ensures the final product meets your expectations.

9. Sustainability and Ethics: Evaluate the supplier’s sustainability practices and ethical standards. Opting for environmentally responsible suppliers can enhance your company’s reputation and reduce environmental impact.

10. Communication and Support: Ensure effective communication channels with the supplier. Responsive customer support is crucial for resolving issues promptly and maintaining a smooth procurement process.

By considering these factors, you can ensure a successful procurement process, yielding high-quality laser-cut metal parts that meet your specifications and business needs.

FAQs on Sourcing and Manufacturing from laser cut metal in China

When sourcing laser cut metal from China, consider these FAQs:

1. Why choose China for laser cut metal?

China offers competitive pricing and a wide range of manufacturing capabilities, including advanced laser cutting technologies.

2. How can I find reliable manufacturers?

Use online platforms like Alibaba or Global Sources to find suppliers. Verify their credibility through reviews, certifications, and direct communication.

3. What should I consider before placing an order?

Clarify specifications such as material type, thickness, tolerances, and finishing requirements. Request samples to assess quality.

4. How do I manage quality control?

Define quality standards in your contract. Consider hiring a third-party inspection service to ensure compliance with specifications.

5. What are common challenges in manufacturing in China?

Communication barriers, intellectual property protection, and logistics delays are common. Address these through clear contracts and regular updates.

6. How can I ensure intellectual property protection?

Use Non-Disclosure Agreements (NDAs) and clearly define ownership of designs. Consider registering patents or trademarks in China if necessary.

7. What are the shipping and logistics considerations?

Plan for shipping costs, import duties, and transit times. Choose reputable freight forwarders to handle logistics.

8. How can I handle language barriers?

Hire a translator or work with manufacturers proficient in English. Ensure all communication is clear and documented.

9. What are the payment terms and methods?

Negotiate payment terms that balance security and flexibility. Consider using secure methods like letters of credit or Alibaba’s Trade Assurance.

10. What should I do if issues arise during manufacturing?

Maintain open communication with the manufacturer. Document issues and work together to find solutions promptly.

By addressing these FAQs, you can navigate sourcing and manufacturing laser cut metal from China more effectively.