“Reliable SourcifyChina Factory Specializing in Precision Laser Cutting of Metal Products”

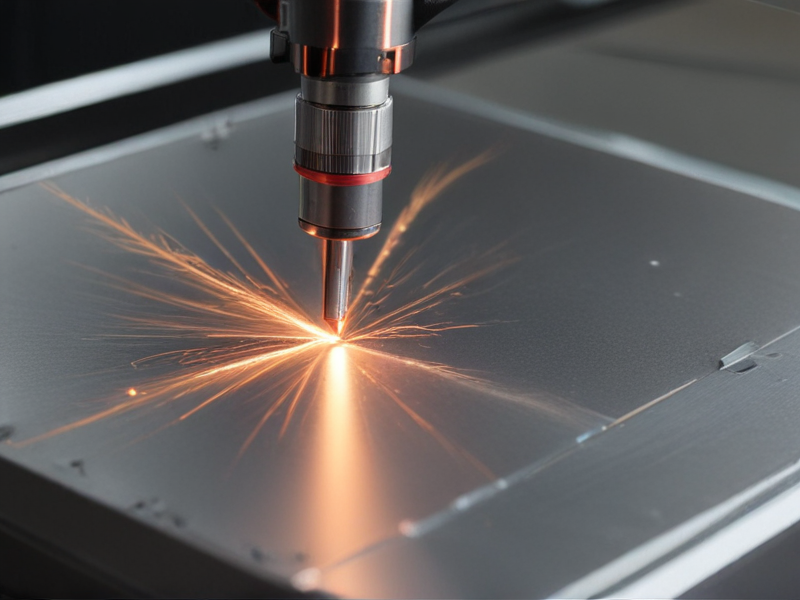

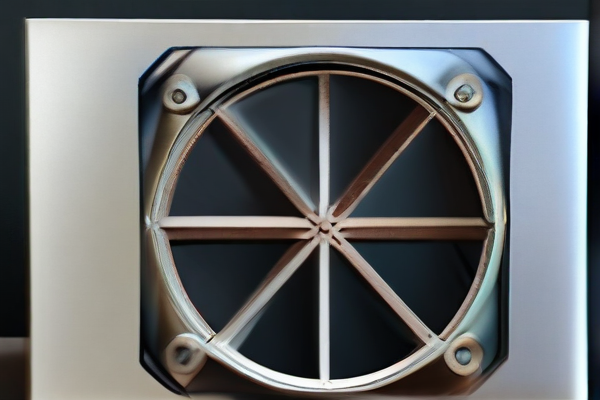

At SourcifyChina, our factory stands out as a reliable source for high-quality laser cutting of metal products. Our state-of-the-art equipment and skilled technicians ensure precise cuts, catering to diverse industry needs. We pride ourselves on our commitment to excellence, offering customized solutions for various applications. Our services cover a wide range of metals, ensuring durability and accuracy in every project. Partner with SourcifyChina for your metal fabrication needs and experience the best in laser cutting technology. Our dedication to quality and customer satisfaction makes us a trusted name in the industry.

Why Choose “SourcifyChina” Factory for Laser Cutting Metal from China?

“SourcifyChina” offers cutting-edge laser cutting technology that ensures precision and efficiency in metal fabrication. Their state-of-the-art equipment guarantees high-quality cuts for various industrial applications, meeting diverse customer needs.

The factory’s experienced team of engineers and technicians provides exceptional expertise in metal cutting. Their deep knowledge and commitment to excellence result in superior craftsmanship and consistent quality, setting them apart from competitors.

Moreover, “SourcifyChina” maintains strict quality control measures throughout the production process. They adhere to international standards, ensuring that every piece meets or exceeds customer expectations, thus building trust and reliability in their services.

Competitive pricing is another key advantage of choosing “SourcifyChina.” They offer cost-effective solutions without compromising on quality, making them an attractive option for businesses looking to maximize their investment in metal fabrication.

Additionally, the factory provides comprehensive customer support, assisting buyers from the initial consultation through to delivery. Their responsive and professional service ensures a smooth and hassle-free purchasing experience, fostering long-term partnerships with clients.

In conclusion, “SourcifyChina” Factory is the ideal choice for buyers seeking high-quality, precision laser cutting metal services from China. Their advanced technology, skilled workforce, stringent quality control, competitive pricing, and excellent customer support make them a reliable and efficient partner in the metal fabrication industry.

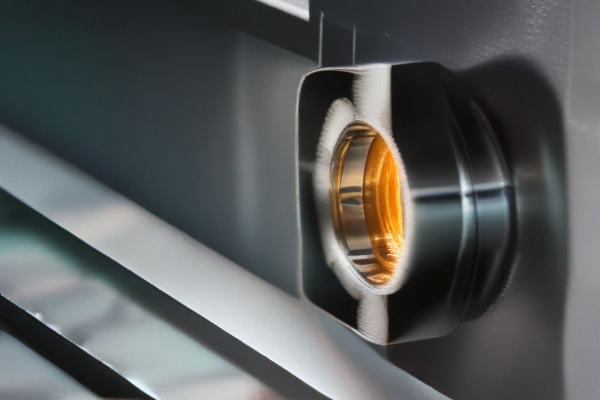

Laser cutting metal involves using high-powered lasers to precisely cut and shape various types of metals. This technique is widely used in industries for its accuracy and efficiency. There are several types of laser cutting methods and options available:

– CO2 Laser Cutting: Ideal for cutting, boring, and engraving materials like stainless steel, aluminum, and titanium.

– Fiber Laser Cutting: Known for its high efficiency and speed, suitable for cutting both thin and thick metals.

– Nd:YAG Laser Cutting: Used for high power applications, capable of cutting metals like steel and aluminum.

– Plasma Laser Cutting: Commonly used for cutting thick metals, providing a clean and precise cut.

– Water Jet Laser Cutting: Combines laser cutting with water jets for cutting metals without generating heat.

Each type of laser cutting offers unique benefits depending on the material and the requirements of the project.

Laser cutting metal is a precise and efficient method used in various industries for creating intricate designs and shapes. It offers high accuracy, minimal waste, and the ability to cut complex geometries.

– Automotive industry: manufacturing parts and components

– Aerospace: cutting high-strength materials

– Electronics: creating small, precise components

– Medical devices: producing surgical instruments

– Jewelry: crafting detailed designs

– Construction: fabricating structural elements

– Art and sculpture: creating intricate metal artworks

– Signage: producing custom metal signs

– Prototyping: rapid creation of metal prototypes

SourcifyChina offers high-quality laser cutting services for various metals, including steel, aluminum, and copper. The precision of their laser cutting technology ensures clean, accurate cuts, minimizing waste and reducing production time. Their services are suitable for industries requiring intricate designs and precise dimensions.

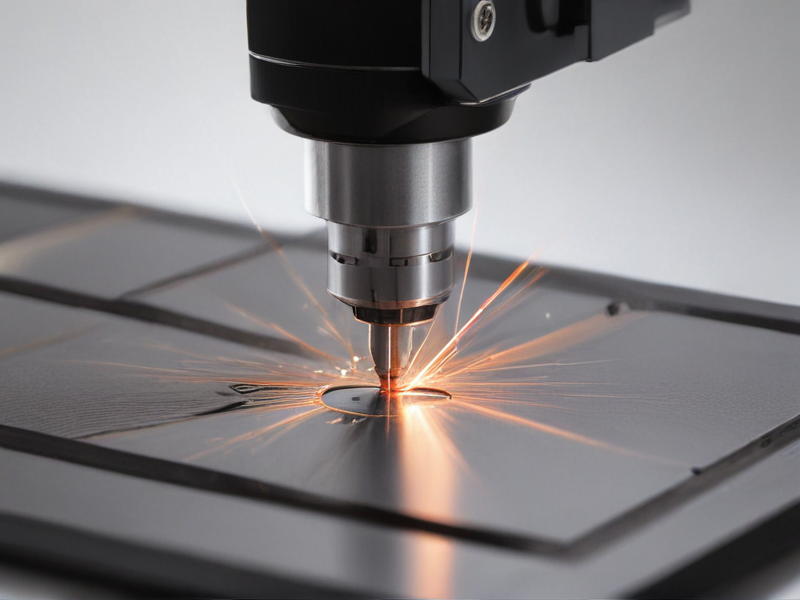

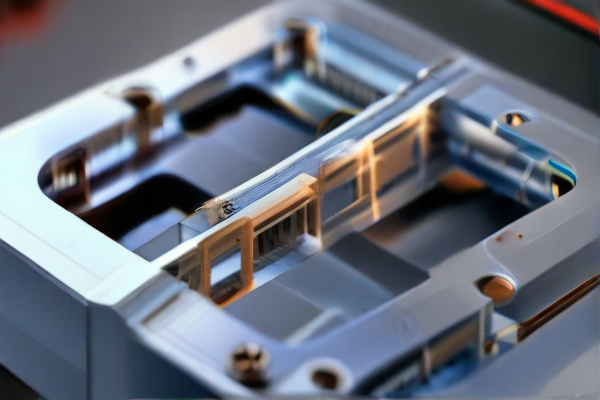

The company utilizes advanced machinery that can handle different thicknesses and sizes, accommodating a wide range of project specifications. Their laser cutting process is known for its efficiency and consistency, producing smooth edges and detailed patterns without the need for secondary finishing.

SourcifyChina’s expertise in laser cutting metal extends to custom projects, enabling clients to achieve specific design requirements. Their team works closely with customers to ensure the final product meets exact specifications, maintaining high standards of quality and reliability.

The use of laser technology in metal cutting also allows for flexibility in design, making it possible to create complex shapes and patterns. SourcifyChina’s commitment to innovation and precision in laser cutting metal ensures that clients receive top-notch products that meet their unique needs.

SourcifyChina employs rigorous quality control in its laser cutting metal manufacturing process. The initial step involves precise material selection to ensure only top-grade metals are used. This guarantees durability and performance in the final products.

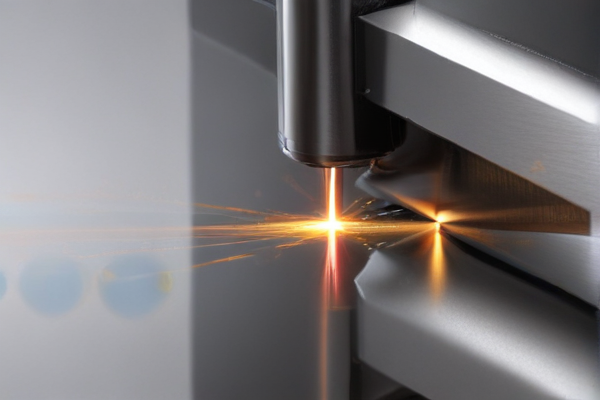

Advanced laser cutting technology is utilized, allowing for high precision and minimal waste. The lasers are regularly calibrated and maintained to ensure consistent performance and accuracy.

Skilled technicians oversee the entire process, from programming the laser cutters to inspecting the final cuts. This human oversight ensures that any anomalies are quickly identified and rectified.

Post-cutting, each metal piece undergoes thorough quality inspections. Dimensional accuracy, edge smoothness, and structural integrity are all meticulously checked. Any defects found are addressed immediately to maintain the highest standards.

Continuous improvement practices are also implemented. Feedback from clients and internal audits are regularly reviewed to enhance the process. This commitment to quality ensures that SourcifyChina consistently delivers superior laser-cut metal products.

SourcifyChina specializes in laser cutting metal with exceptional precision and efficiency. Their advanced laser cutting technology ensures tight tolerances and high-quality finishes on various metals like steel, aluminum, and titanium. The company leverages state-of-the-art machinery to handle both small and large-scale projects, catering to diverse industrial needs.

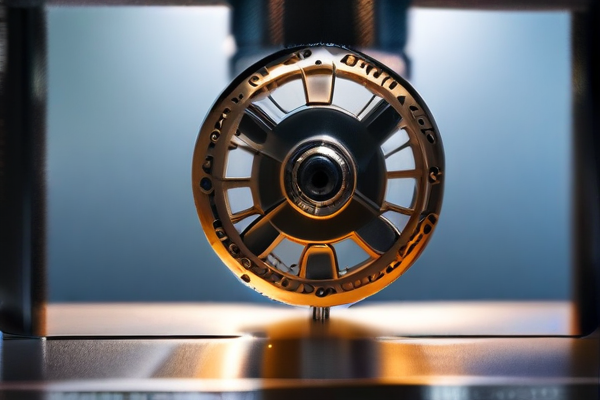

Their laser0: cutting capabilities include intricate patterns and complex geometries that traditional0: cutting methods cannot achieve. This ability to create detailed designs makes SourcifyChina a preferred choice for industries requiring high customization levels, such as aerospace, automotive,0: and decorative metalwork.

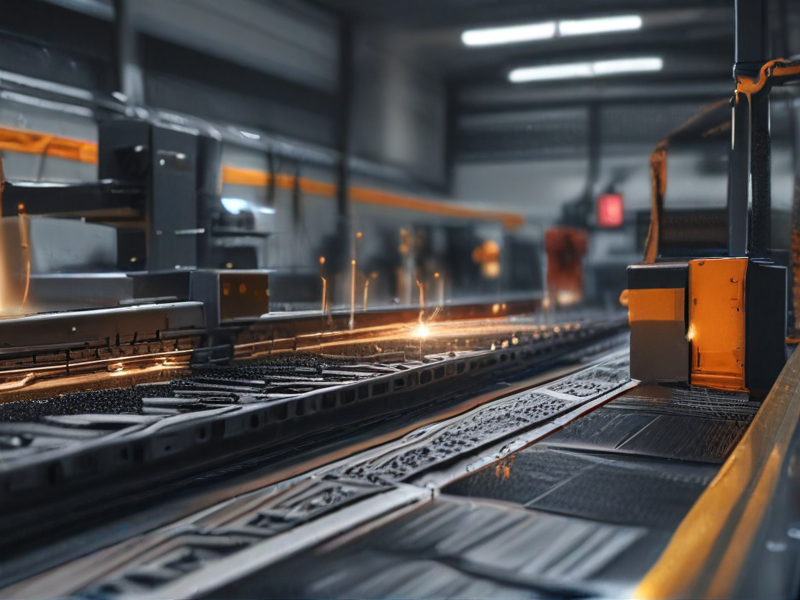

In addition to precision, SourcifyChina prioritizes speed0: and cost-effectiveness. Their automated systems reduce production time and labor costs, providing clients with timely and budget-friendly solutions. Whether it’s prototyping or mass production, SourcifyChina ensures consistent quality and timely delivery.

SourcifyChina also emphasizes sustainability in its operations. Their laser cutting processes generate minimal waste, and they follow strict environmental guidelines to reduce their carbon footprint. This commitment to eco-friendly practices appeals to environmentally conscious0: clients seeking reliable manufacturing partners.

The company offers comprehensive services, including material selection, design consultation, and post-processing treatments0: like powder coating and anodizing. This one-stop service approach simplifies the supply chain and enhances customer satisfaction. SourcifyChina’s expertise and dedication to quality make them a leading provider in the laser cutting industry.

Their team of skilled engineers and technicians works closely with0: clients to understand their specific requirements and deliver tailor-made solutions. This collaborative approach ensures that each project meets the highest standards of excellence and functionality.

SourcifyChina’s continuous investment in technology and training keeps0: them at the forefront of the industry. By embracing innovation and maintaining a customer-centric focus, they consistently exceed client expectations and set new benchmarks in laser cutting0: metal capabilities.

Laser cutting metal offers precise and efficient cutting, making it an invaluable technique in various industries. This method provides numerous benefits, including accuracy, speed, and versatility.

– High Precision: Laser cutting delivers exact cuts with minimal tolerance, reducing material waste.

– Efficiency: The process is faster than traditional methods, increasing productivity.

– Versatility: Suitable for various metals and thicknesses, from steel to aluminum.

– Quality Edges: Produces clean, burr-free edges, minimizing the need for additional finishing.

– Automation Potential: Easily integrated with CNC systems for automated and repeatable cutting processes.

– Minimal Distortion: Reduced heat-affected zones preserve material integrity.

– Complex Shapes: Capable of cutting intricate patterns and designs with ease.

Laser cutting metal offers precision, efficiency, and versatility, making it a preferred method in various industries for creating intricate designs and shapes.

– Precision: Laser cutting provides high accuracy, capable of cutting with tolerances as fine as 0.001 inches.

– Speed: The process is fast, enabling quick production runs and reducing lead times.

– Versatility: It can cut various metals, including steel, aluminum, and titanium.

– Quality: Produces clean edges and smooth finishes, minimizing the need for additional processing.

– Automation: Easily integrated with CNC machines, allowing for automated, repeatable, and scalable operations.

– Complexity: Capable of handling complex geometries and intricate patterns without compromising quality.

– Material Efficiency: Minimizes waste through precise cutting paths, optimizing material usage.

– Heat Affected Zone (HAZ): Creates a small HAZ, reducing thermal distortion and preserving material properties.

– Cost-Effective: Reduces labor and material costs through efficient and automated processes.

– Flexibility: Suitable for both prototyping and large-scale production, adapting to different project needs.

SourcifyChina specializes in custom laser cutting metal products, delivering precision and quality. Their advanced technology ensures intricate designs and high accuracy in every project.

Clients can rely on SourcifyChina for bespoke metal components tailored to specific needs. Their expertise spans various industries, including automotive, aerospace, and manufacturing.

The company offers a range of services, from prototyping to mass production, all underpinned by rigorous quality control. This guarantees consistent results and customer satisfaction.

SourcifyChina’s commitment to innovation and excellence makes them a trusted partner for all laser cutting metal projects, providing efficient and cost-effective solutions.

SourcifyChina Laser Cutting Metal is a premier Chinese company specializing in precision laser cutting services for a wide array of metals. Leveraging advanced laser cutting technology, the company delivers high-quality, precise cuts that meet the stringent requirements of diverse industries, including automotive, aerospace, and manufacturing. SourcifyChina prides itself on its state-of-the-art equipment and skilled workforce, ensuring exceptional accuracy and efficiency in every project. Their comprehensive service offerings include cutting, shaping, and finishing various metals such as stainless steel, aluminum, and carbon steel, catering to both large-scale production and custom, intricate designs. Committed to excellence, SourcifyChina combines innovative techniques with rigorous quality control measures to provide solutions that not only meet but exceed customer expectations. This dedication to superior service has established SourcifyChina as a trusted partner for businesses seeking reliable and precise metal cutting solutions.

Laser cutting metal is a critical technology in the aerospace, defense, and marine industries due to its precision, efficiency, and versatility. In aerospace, laser cutting is used to fabricate intricate components from high-strength alloys, ensuring minimal material wastage and superior accuracy. The ability to produce complex geometries with tight tolerances is essential for creating lightweight structures that meet stringent performance and safety standards. For example, laser cutting is utilized in manufacturing aircraft skins, engine components, and structural parts, contributing to overall weight reduction and fuel efficiency. This precision ensures consistent quality in high-stress applications, where failure is not an option.

In the defense and marine sectors, laser cutting plays a pivotal role in the production of robust and durable components. Defense applications benefit from the technology’s capability to cut through thick, tough materials used in armor plating and vehicle parts, enhancing the protection and resilience of military equipment. The marine industry leverages laser cutting for the construction and repair of ships and submarines, where the process is used to cut large metal sheets with exceptional precision. This technology allows for the creation of intricate shapes and sizes needed for hulls, decks, and other structural components, improving overall vessel performance and longevity. The high precision and efficiency of laser cutting ensure that both sectors can meet their rigorous demands for durability and reliability.

In the automotive industry, laser cutting metal is a transformative technology that enhances precision, efficiency, and design flexibility. Laser cutting enables the production of complex geometries and intricate parts with high accuracy, crucial for modern automotive components that demand stringent tolerances. This technology is widely employed in the manufacturing of car bodies, chassis, and various small components such as brackets and gears. The high-speed and non-contact nature of laser cutting reduces production times and minimizes material wastage, leading to cost-effective manufacturing processes. Additionally, the ability to easily integrate laser cutting systems into automated production lines streamlines operations and improves overall productivity, making it an indispensable tool in automotive manufacturing.

In the electronics sector, laser cutting metal plays a critical role in the fabrication of precise and miniaturized components required for modern electronic devices. The technology is essential for cutting thin metal sheets used in the production of enclosures, circuit boards, and connectors. Laser cutting’s precision allows for the creation of intricate patterns and fine features that are often necessary in electronics, ensuring reliable and high-performance end products. Furthermore, the ability to work with various metals, including copper and aluminum, makes laser cutting versatile and suitable for a wide range of electronic applications. The non-contact nature of the process also reduces the risk of damaging sensitive components, which is vital in maintaining the integrity and functionality of electronic devices.

Laser cutting metal has significantly transformed the construction industry by providing precision and efficiency in material handling and structural fabrication. This technology allows for the accurate cutting of complex shapes and patterns in metal sheets, beams, and other structural components, which is crucial for modern architectural designs and engineering specifications. The high precision of laser cutting reduces material wastage and the need for secondary finishing processes, thereby lowering production costs and enhancing project timelines. Additionally, the ability to cut through various metal thicknesses with minimal distortion ensures the structural integrity and aesthetic quality of construction elements, facilitating the creation of innovative and durable building structures.

In the energy sector, laser cutting metal plays a pivotal role in the manufacturing and maintenance of energy systems, particularly in the production of components for renewable energy technologies like wind turbines, solar panels, and fuel cells. The precision and versatility of laser cutting enable the fabrication of intricate parts required for high-efficiency energy systems, such as the finely detailed blades of wind turbines and the delicate components of photovoltaic cells. Moreover, laser cutting is essential in the maintenance and repair of energy infrastructure, allowing for quick and accurate modifications and replacements of worn-out parts. This capability enhances the reliability and efficiency of energy systems, contributing to the advancement of sustainable energy solutions and the overall reduction of carbon footprints.

Laser cutting metal is a pivotal technology in the industrial equipment industry, revolutionizing the way components are manufactured and assembled. Utilizing high-powered lasers, this process precisely cuts through various metals, including steel, aluminum, and titanium, to create intricate designs and components. The precision and speed of laser cutting significantly enhance production efficiency, reducing waste and ensuring consistent quality across large production runs. This technology is particularly beneficial in industries where precision is paramount, such as aerospace, automotive, and medical device manufacturing. By enabling complex geometries and fine detailing that traditional cutting methods struggle to achieve, laser cutting has become indispensable for modern industrial operations.

In addition to its precision, laser cutting offers remarkable versatility and flexibility, accommodating a wide range of materials and thicknesses. This adaptability allows manufacturers to swiftly pivot between different projects without extensive retooling, thus optimizing production schedules and reducing downtime. The non-contact nature of laser cutting also minimizes the risk of material deformation, ensuring the structural integrity of delicate components. Moreover, advancements in laser technology, such as fiber lasers and CO2 lasers, have further expanded the capabilities of metal cutting, providing manufacturers with more options to tailor their processes to specific requirements. Overall, laser cutting metal stands as a cornerstone in the industrial equipment industry, driving innovation and efficiency in manufacturing practices.

Laser cutting metal is a crucial technology in the medical device industry, enabling the production of highly precise and intricate components essential for various medical applications. This technology uses a focused laser beam to cut metals with extreme accuracy, allowing for the creation of complex geometries and fine features that are often required in medical devices such as surgical instruments, stents, and implants. The precision of laser cutting ensures that these components meet stringent medical standards and specifications, which is vital for patient safety and the effectiveness of medical treatments. Moreover, laser cutting can be used on a variety of biocompatible metals, including stainless steel and titanium, which are commonly used in medical devices due to their strength, durability, and compatibility with the human body.

Beyond precision and material compatibility, laser cutting offers significant advantages in terms of manufacturing efficiency and scalability. The non-contact nature of laser cutting reduces the risk of contamination and damage to the metal, maintaining the integrity and sterility required for medical applications. Additionally, the technology allows for rapid prototyping and quick adjustments to design, which accelerates the development process for new medical devices. This is particularly important in the fast-evolving medical field, where innovation and timely deployment of new technologies can significantly impact patient care. The capability to produce small batch sizes with consistent quality also makes laser cutting an ideal choice for custom medical devices tailored to individual patient needs, further enhancing personalized medicine approaches.

Laser cutting metal is a highly precise and efficient machining technique employed in modern manufacturing. Utilizing a concentrated laser beam, this method can cut through a variety of metals with exceptional accuracy and minimal material waste. The laser’s intensity and focal precision enable it to create intricate shapes and designs that traditional cutting methods might struggle with. This capability is particularly beneficial for industries requiring complex components, such as aerospace, automotive, and electronics. Additionally, laser cutting offers a clean edge finish, reducing the need for secondary processing and enhancing the overall production speed.

In manufacturing, laser cutting metal is valued for its versatility and automation potential. Advanced computer numerical control (CNC) systems can guide the laser with high precision, making it suitable for both prototype development and large-scale production. This automation not only improves consistency and quality but also lowers labor costs. Moreover, laser cutting is adaptable to different metals, including stainless steel, aluminum, and titanium, making it an integral part of various manufacturing processes. The ability to quickly switch between different cutting patterns and materials without significant downtime further underscores its efficiency, making laser cutting a cornerstone of modern manufacturing technology.

Sure, here are some frequently asked questions (FAQ) with answers for manufacturing “laser cutting metal quality work from SourcifyChina factory”:

What types of metals can SourcifyChina laser cut?

SourcifyChina can laser cut a variety of metals including stainless steel, carbon steel, aluminum, brass, and copper. We accommodate various thicknesses depending on the metal type.

What is the maximum thickness of metal that can be laser cut?

For carbon steel, we can cut up to 25mm. For stainless steel, the maximum thickness is 20mm, and for aluminum, it is 15mm.

How accurate is the laser cutting process?

Our laser cutting process offers high precision with a tolerance of +/- 0.1mm. This ensures that parts are cut with exceptional accuracy.

What are the benefits of laser cutting over other cutting methods?

Laser cutting provides precise cuts, minimal material waste, faster production times, and the ability to cut complex shapes with smooth edges. It’s also ideal for both small and large batch productions.

Can you provide custom designs for laser cutting?

Yes, we accept custom design files in various formats such as DXF, DWG, and AI. Our team can also assist with design modifications to ensure optimal cutting quality.

What is the typical lead time for laser cutting orders?

The lead time depends on the complexity and quantity of the order. Generally, small to medium-sized orders take 5-7 business days. Larger orders may require more time.

Do you offer any post-processing services?

Yes, we offer a range of post-processing services including deburring, bending, welding, powder coating, and assembly to meet your specific requirements.

How do you ensure the quality of laser-cut parts?

We have a rigorous quality control process in place, including inspections at multiple stages of production to ensure the parts meet the highest standards of quality and precision.

What is the cost structure for laser cutting services?

Pricing is based on factors such as material type, thickness, complexity of the design, and quantity. Contact us for a detailed quote tailored to your project needs.

How can I place an order with SourcifyChina?

You can place an order by contacting our sales team through our website, email, or phone. Provide your design files and specifications, and we will guide you through the process.

Laser cutting metal manufacturing from SourcifyChina factory involves precision and efficiency in metal fabrication. Here are some tips to ensure optimal results:

1. Material Selection: Choose the right type of metal suitable for laser cutting. Commonly used metals include stainless steel, aluminum, and carbon steel. Each metal has unique properties affecting the cutting process.

2. Thickness Consideration: The thickness of the metal significantly impacts the cutting speed and quality. Thicker materials require more powerful lasers and slower cutting speeds.

3. Laser Power: Adjust the laser power according to the metal type and thickness. Higher power settings are necessary for thicker and denser metals.

4. Focus and Alignment: Ensure the laser is properly focused and aligned. Accurate focus enhances the precision of cuts and reduces the risk of defects.

5. Cutting Speed: Optimize the cutting speed based on the material and design complexity. Too fast can cause incomplete cuts; too slow can lead to excessive heat buildup and warping.

6. Assist Gas Selection: Use the appropriate assist gas (such as oxygen, nitrogen, or air) to improve cutting performance. Oxygen is typically used for carbon steels, while nitrogen is preferred for stainless steel and aluminum to prevent oxidation.

7. Design Optimization: Simplify designs to reduce cutting time and material waste. Avoid intricate details that may be challenging to cut cleanly.

8. Regular Maintenance: Keep the laser cutting machine well-maintained. Regularly clean the lenses, check the nozzles, and ensure the cooling system is functioning correctly.

9. Quality Control: Implement a robust quality control process to inspect the finished parts for accuracy and consistency. Use precision measuring tools to verify dimensions and tolerances.

10. Training and Safety: Ensure operators are well-trained and adhere to safety protocols. Proper handling of equipment and materials minimizes risks and enhances productivity.

Following these tips can help achieve high-quality laser cutting results from SourcifyChina factory, ensuring efficient and precise metal manufacturing.

What materials can SourcifyChina factory laser cut?

SourcifyChina factory specializes in laser cutting a variety of metals including stainless steel, aluminum, carbon steel, brass, and copper. Custom requests for other metals can also be accommodated.

What thickness of metal can be cut?

The factory can cut metals ranging from 0.5mm to 20mm in thickness. The precise cutting capability depends on the type of metal.

What is the lead time for laser cutting orders?

Typical lead time ranges from 7 to 15 days, depending on the complexity and volume of the order. Expedited services are available upon request.

Do you provide design assistance for laser cutting projects?

Yes, SourcifyChina offers design assistance. Clients can submit their CAD files or request help to create custom designs suitable for laser cutting.

What file formats are accepted for laser cutting designs?

Accepted file formats include DXF, DWG, AI, and PDF. If you have a different format, contact us for compatibility confirmation.

Is there a minimum order quantity?

There is no strict minimum order quantity. Both small and large volume orders are welcome.

What quality control measures are in place?

The factory adheres to strict quality control procedures including pre-production samples, in-process inspections, and final product checks to ensure precision and quality.

Can you provide finishing services after laser cutting?

Yes, we offer a range of finishing services including polishing, painting, powder coating, and anodizing to meet your specific needs.

What are the payment terms?

Payment terms typically require a 30% deposit upfront with the balance due upon completion. Flexible terms can be discussed for large orders or long-term partnerships.

How do I get a quote for my laser cutting project?

To get a quote, submit your design files and project specifications via our online form or email. We will respond with a detailed quotation within 24 hours.

Sourcing laser cutting metal services from SourcifyChina factory involves several key steps to ensure quality, cost-effectiveness, and reliability. Here are some tips to guide you:

1. Define Your Requirements: Clearly specify the type of metal, thickness, and precision needed. Provide detailed drawings or CAD files to the factory to avoid any miscommunication.

2. Evaluate Factory Capabilities: Ensure SourcifyChina has the necessary technology and expertise for your specific requirements. Check their machinery, production capacity, and quality control processes.

3. Request Samples: Before placing a large order, request sample cuts to assess the quality of their work. Examine the samples for precision, edge quality, and consistency.

4. Verify Certifications: Ensure the factory holds relevant certifications, such as ISO 9001, which indicates adherence to quality management standards.

5. Negotiate Terms: Discuss pricing, payment terms, and delivery schedules. Be clear about your expectations regarding lead times and shipping logistics to avoid delays.

6. Check References and Reviews: Look for feedback from other clients who have worked with SourcifyChina. Positive reviews and testimonials can provide assurance of their reliability and quality.

7. Inspect Quality Control Processes: Inquire about their quality control measures and inspection processes. This includes checking if they conduct regular inspections and tests on their products.

8. Use Secure Payment Methods: Opt for secure payment methods and consider using a third-party escrow service to protect your payment until you receive and verify the quality of the goods.

9. Establish Clear Communication: Maintain regular communication with the factory throughout the production process. Use clear and concise language to avoid misunderstandings.

10. Plan for Contingencies: Have a backup plan in case of delays or issues with the order. This might include alternative suppliers or additional lead time.

By following these tips, you can effectively source laser cutting metal services from SourcifyChina, ensuring a smooth and successful procurement process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.