Technology and Applications of low alloy steel vs stainless steel

Low alloy steels and stainless steels each excel in different applications due to their unique compositions and properties.

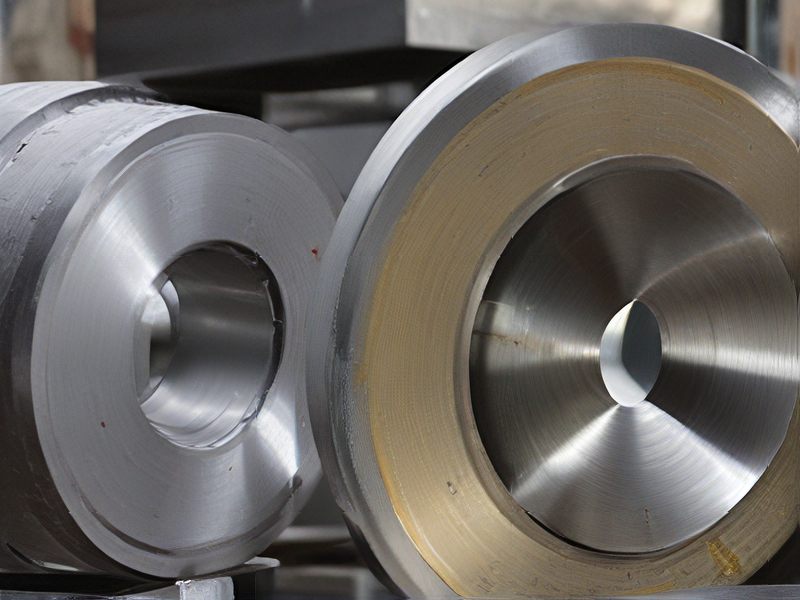

Low alloy steels, containing small amounts of alloying elements like manganese, chromium, or nickel, offer enhanced strength, toughness, and corrosion resistance compared to plain carbon steel. They find use in construction (bridges, buildings), automotive components (chassis, axles), and manufacturing (tools, machinery).

Stainless steels, known for their high chromium content (at least 10.5%), boast remarkable corrosion resistance, making them ideal for food processing equipment, medical instruments, and chemical processing plants.

However, stainless steel is generally more expensive than low alloy steel.

Ultimately, the choice between the two depends on the specific application’s requirements for strength, corrosion resistance, and budget.

Quality Testing Methods for low alloy steel vs stainless steel and how to control quality

Quality testing methods for low alloy steel and stainless steel typically focus on different aspects due to their distinct compositions and applications:

Quality Testing Methods:

Low Alloy Steel:

1. Chemical Composition Analysis: Using techniques like spectroscopy or chemical analysis to ensure the correct alloying elements are present in the required proportions.

2. Mechanical Testing: Includes tests like tensile strength, hardness, impact resistance, and fatigue testing to verify performance under stress.

3. Microstructure Examination: Utilizing metallography to assess grain structure, inclusion content, and phase distribution for integrity.

4. Non-Destructive Testing (NDT): Techniques such as ultrasonic testing (UT), magnetic particle inspection (MPI), or radiographic testing (RT) to detect internal flaws without damaging the material.

Stainless Steel:

1. Chemical Composition Verification: Ensuring the correct levels of chromium, nickel, and other alloying elements to maintain corrosion resistance.

2. Corrosion Testing: Assessing resistance to various corrosive environments through methods like salt spray testing (ASTM B117) or electrochemical tests (potentiodynamic polarization).

3. Surface Finish Inspection: Checking for surface defects, roughness, or contamination that could affect performance.

4. Welding Inspection: Evaluating weld quality using techniques such as liquid penetrant testing (PT) or visual inspection.

Quality Control Measures:

1. Specification Compliance: Ensure materials meet specified standards (e.g., ASTM, ASME) through rigorous testing and documentation.

2. Process Control: Implementing procedures to monitor and control manufacturing processes to minimize variability and ensure consistency.

3. Supplier Quality Assurance: Establishing stringent criteria for suppliers and conducting audits to verify adherence to quality standards.

4. Continuous Improvement: Regular review of testing methods and procedures to incorporate advancements and enhance quality assurance practices.

By employing these methods and control measures, manufacturers can ensure both low alloy steel and stainless steel meet the required quality standards for their intended applications.

Tips for Procurement and Considerations when Purchasing from low alloy steel vs stainless steel

When deciding between low alloy steel and stainless steel for procurement, several key considerations can guide your choice:

1. Corrosion Resistance: Stainless steel is highly resistant to corrosion, making it ideal for environments exposed to moisture or chemicals. Low alloy steel may require additional coatings or treatments to achieve similar protection.

2. Strength and Durability: Both types of steel offer good strength, but low alloy steel often provides higher tensile and yield strength compared to stainless steel, which can be advantageous in structural applications.

3. Cost: Low alloy steel generally costs less than stainless steel, making it more economical for many applications. Consider lifecycle costs, including maintenance and potential replacements, to assess overall cost-effectiveness.

4. Temperature Resistance: Stainless steel exhibits better resistance to high temperatures and thermal expansion than low alloy steel, making it suitable for applications requiring heat resistance.

5. Application Specificity: Determine the specific requirements of your application. For example, if your project involves food processing or medical equipment requiring hygiene standards, stainless steel’s non-reactive and easy-to-clean properties may be essential.

6. Availability and Sourcing: Consider availability from suppliers and any regional preferences or standards that may influence your decision.

7. Environmental Impact: Evaluate the environmental impact of each material throughout its lifecycle, including manufacturing, use, and disposal/recycling considerations.

Ultimately, the choice between low alloy steel and stainless steel hinges on balancing these factors against your project’s requirements, budget, and long-term considerations.

FAQs on Sourcing and Manufacturing from low alloy steel vs stainless steel in China

## Sourcing & Manufacturing FAQ: Low Alloy vs. Stainless Steel in China

Sourcing:

* Availability: Both low alloy and stainless steel are widely available in China, with a vast network of mills and suppliers catering to diverse needs.

* Pricing: Low alloy steel generally offers competitive pricing compared to stainless steel due to lower material costs.

* Quality: China boasts reputable steel producers, but quality can vary. Verify certifications and conduct thorough due diligence when sourcing from new suppliers.

Manufacturing:

* Processing: Both steel types can be processed by Chinese manufacturers, but stainless steel often requires specialized equipment and expertise due to its higher chromium content.

* Fabrication: Low alloy steel is generally easier to weld and shape, while stainless steel demands precision and specialized techniques to avoid corrosion issues.

* Cost: Manufacturing costs for stainless steel are typically higher due to the complexity of processing and specialized equipment.

Considerations:

* Corrosion resistance: Stainless steel excels in resisting corrosion, making it suitable for demanding environments. Low alloy steel offers varying levels of corrosion resistance depending on its composition.

* Strength and durability: Both steel types provide good strength and durability, but specific grades within each category offer different levels of performance.

* Applications: Choose the steel type based on the intended application and required properties.

Remember to carefully evaluate your specific needs and budget when deciding between low alloy and stainless steel in China.