Technology and Applications of majestic steel

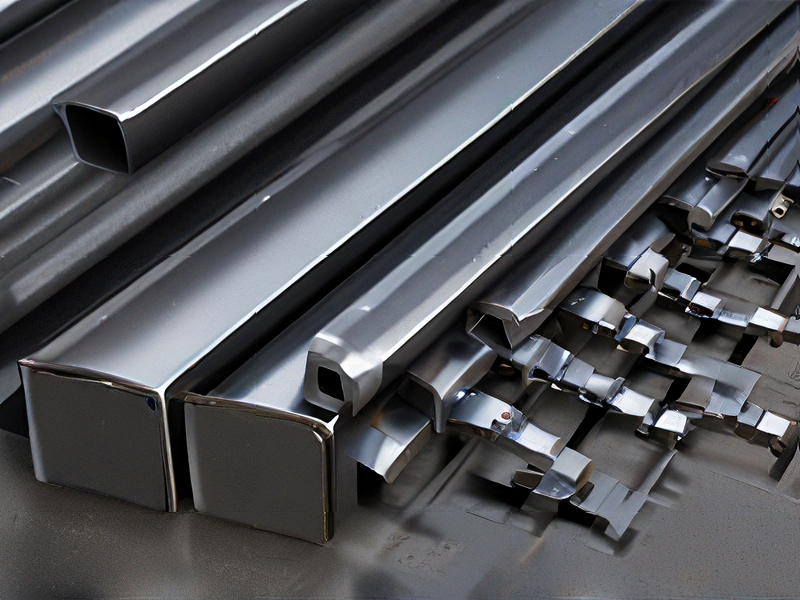

Majestic steel, often referred to as high-performance or advanced steel, is known for its superior strength, durability, and versatility. This type of steel is used in various industries due to its enhanced mechanical properties and resistance to corrosion, wear, and fatigue.

Technology

1. Production Process: Majestic steel is typically produced through advanced metallurgical processes such as alloying, heat treatment, and thermomechanical processing. These methods improve the steel’s microstructure, resulting in better performance characteristics.

2. Advanced Alloys: Incorporation of elements like chromium, nickel, molybdenum, and vanadium in the steel alloy enhances its strength, toughness, and corrosion resistance.

3. Surface Treatments: Techniques such as galvanization, coating, and plating are employed to further enhance the steel’s resistance to environmental factors and extend its lifespan.

Applications

1. Construction: Majestic steel is widely used in construction for building frameworks, bridges, and infrastructure projects. Its high strength-to-weight ratio and durability make it ideal for these applications.

2. Automotive Industry: In the automotive sector, majestic steel is used in the manufacturing of vehicle frames, body panels, and safety components. It helps improve vehicle safety and fuel efficiency by reducing weight without compromising strength.

3. Aerospace: The aerospace industry uses majestic steel for critical components such as landing gear, engine parts, and structural elements due to its exceptional strength and fatigue resistance.

4. Energy Sector: In the energy sector, especially in oil and gas, this steel is used for pipelines, drilling equipment, and offshore structures. Its resistance to harsh environmental conditions is crucial in these applications.

5. Manufacturing: Majestic steel is employed in the manufacturing of machinery, tools, and heavy equipment. Its durability and wear resistance are vital for the longevity and reliability of these products.

In summary, majestic steel’s advanced production technologies and superior properties make it a cornerstone material across multiple industries, offering enhanced performance, safety, and durability.

Quality Testing Methods for majestic steel and how to control quality

For Majestic Steel, quality testing methods and control mechanisms are crucial to ensuring consistent product excellence. Implementing stringent quality control involves several key steps:

1. Raw Material Inspection: Verify the quality of incoming materials through visual inspection, dimensional checks, and material certification validation.

2. Production Process Controls: Monitor critical processes like cutting, forming, and welding using statistical process control (SPC) methods to detect variations and ensure adherence to specifications.

3. Testing and Validation: Conduct thorough testing such as mechanical property testing (tensile strength, hardness), non-destructive testing (ultrasonic testing, X-ray inspection), and dimensional checks during and after production.

4. Quality Assurance Team: Employ a dedicated team to oversee quality at each stage, with trained inspectors performing regular audits and spot checks.

5. Documented Procedures: Maintain clear, standardized procedures for all quality-related activities, including protocols for handling non-conforming products.

6. Continuous Improvement: Implement feedback loops from quality issues to drive corrective actions and preventive measures, fostering a culture of continuous improvement.

By integrating these methods, Majestic Steel can uphold high standards, meet customer expectations, and sustain competitiveness in the market.

Tips for Procurement and Considerations when Purchasing from majestic steel

Tips for Procurement from Majestic Steel

1. Assess Your Needs:

– Clearly define the type, grade, and quantity of steel required for your project to ensure you get the right product.

2. Supplier Evaluation:

– Research Majestic Steel’s reputation, financial stability, and customer reviews to ensure reliability and quality service.

3. Quality Assurance:

– Verify the steel meets industry standards and certifications. Request quality assurance documents and test certificates.

4. Pricing:

– Request quotes and compare with other suppliers. Consider long-term contracts for better pricing and stability.

5. Lead Times:

– Understand Majestic Steel’s lead times and ensure they align with your project timelines to avoid delays.

6. Supply Chain Integration:

– Check if Majestic Steel offers supply chain integration services such as inventory management, JIT delivery, and logistics support.

7. Sustainability:

– Evaluate their sustainability practices and eco-friendly initiatives. This can be crucial for companies with green policies.

8. Payment Terms:

– Negotiate favorable payment terms that match your cash flow needs. Understand all financial commitments before finalizing the purchase.

Considerations when Purchasing

1. Material Specifications:

– Ensure the specifications match your requirements, including tensile strength, durability, and corrosion resistance.

2. Cost Analysis:

– Factor in all costs, including shipping, handling, and potential tariffs. Look for hidden costs that could impact the overall budget.

3. Vendor Support:

– Evaluate the level of customer support and after-sales service Majestic Steel offers, including technical assistance and return policies.

4. Delivery and Logistics:

– Confirm the logistics capabilities of Majestic Steel. Ensure they can deliver to your location within the required timeframe.

5. Contract Terms:

– Thoroughly review contract terms, including clauses related to delays, cancellations, and liabilities.

6. Technology and Innovation:

– Assess the technological capabilities of Majestic Steel, such as advanced manufacturing processes and digital procurement platforms.

By following these tips and considerations, you can streamline the procurement process and ensure a successful purchase from Majestic Steel.

FAQs on Sourcing and Manufacturing from majestic steel in China

FAQs on Sourcing and Manufacturing from Majestic Steel in China

1. What products does Majestic Steel offer?

Majestic Steel provides a wide range of steel products, including galvanized, galvalume, pre-painted, cold-rolled, and hot-rolled steel. These products cater to various industries such as construction, automotive, and appliances.

2. Why source from Majestic Steel in China?

Sourcing from Majestic Steel in China offers competitive pricing, high-quality products, and access to a large manufacturing base. China’s advanced production capabilities and efficient logistics also ensure timely delivery.

3. How do I ensure the quality of the steel products?

Majestic Steel adheres to stringent quality control processes. They are ISO certified and employ rigorous testing methods. Additionally, customers can request third-party inspections to verify quality.

4. What are the lead times for orders?

Lead times vary based on product type and order size. Typically, it ranges from 4 to 8 weeks, including production and shipping. Majestic Steel provides detailed timelines during the order confirmation process.

5. Can Majestic Steel handle custom orders?

Yes, Majestic Steel offers customization options to meet specific requirements. This includes custom sizes, coatings, and finishes. Customers should provide detailed specifications when placing orders.

6. What are the payment terms?

Payment terms are generally flexible, with options such as Letter of Credit (L/C), Telegraphic Transfer (T/T), and open account terms for established customers. Specific terms are negotiated during the contract stage.

7. How is shipping and logistics managed?

Majestic Steel has an experienced logistics team that coordinates with major shipping lines. They handle all aspects of shipping, including documentation, customs clearance, and delivery to the specified location.

8. Is there customer support available?

Yes, Majestic Steel offers comprehensive customer support, including pre-sales consultation, order tracking, and post-sales assistance. They provide dedicated account managers to assist with any inquiries.

9. Are there sustainability initiatives in place?

Majestic Steel is committed to sustainability, implementing eco-friendly practices in production. They focus on reducing emissions, recycling waste, and using energy-efficient technologies.

10. How can I place an order with Majestic Steel?

Orders can be placed directly through the Majestic Steel website or by contacting their sales team via email or phone. Detailed order instructions and support are provided to ensure a smooth process.