Technology and Applications of mechanical part

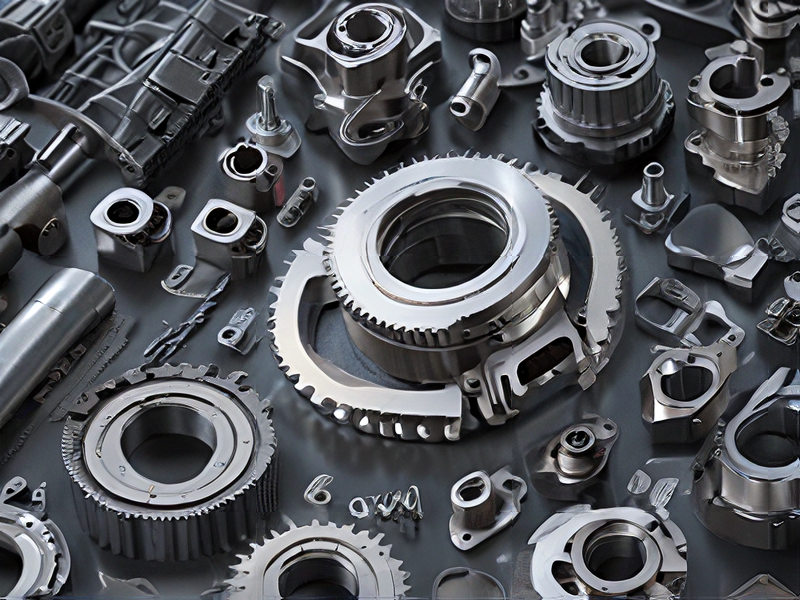

Mechanical parts encompass a wide array of technologies and applications crucial to various industries. These parts are fundamental components in machinery, vehicles, and equipment, enabling mechanical functions across sectors like manufacturing, aerospace, automotive, and more.

Technologies:

1. CAD (Computer-Aided Design): CAD software allows engineers to design and simulate mechanical parts with precision, improving efficiency and reducing errors.

2. CAM (Computer-Aided Manufacturing): CAM software translates CAD designs into instructions for automated manufacturing processes, such as CNC machining, ensuring accuracy and repeatability.

3. Materials and Metallurgy: Advances in materials science have led to the development of high-performance alloys, composites, and polymers tailored for specific mechanical properties like strength, durability, and weight.

4. Simulation and Analysis: Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulate mechanical behavior under different conditions, optimizing designs for performance and safety.

Applications:

1. Automotive Industry: Mechanical parts such as engines, transmissions, and suspension systems are critical for vehicle performance and safety.

2. Manufacturing: Robotics, conveyor systems, and precision machinery rely on mechanical parts for automation and production efficiency.

3. Aerospace: Aircraft propulsion systems, landing gear, and control surfaces require robust mechanical parts to ensure reliability and safety in extreme environments.

4. Consumer Electronics: Precision components like actuators, gears, and bearings are essential in devices ranging from smartphones to household appliances.

Mechanical parts continue to evolve with advancements in materials, manufacturing processes, and digital technologies, driving innovation across industries and enabling new capabilities in automation, sustainability, and performance optimization.

Quality Testing Methods for mechanical part and how to control quality

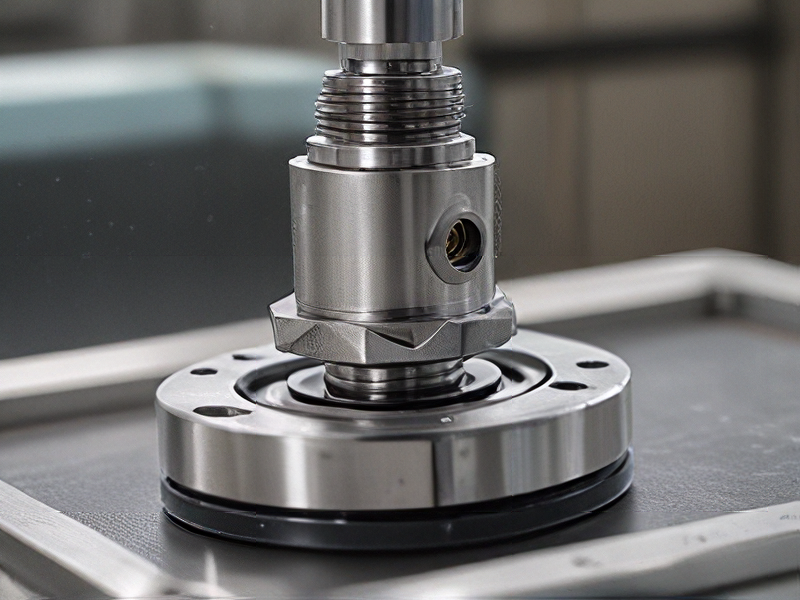

Quality testing methods for mechanical parts typically involve a combination of destructive and non-destructive techniques to ensure reliability and adherence to specifications. Non-destructive testing (NDT) methods include visual inspection, ultrasonic testing (UT), magnetic particle testing (MPT), dye penetrant testing (DPT), and radiographic testing (RT). These methods detect surface defects, internal flaws, and structural integrity without damaging the part.

Destructive testing methods, such as tensile testing, hardness testing, and impact testing, are used to understand material properties and failure points under stress conditions. These tests provide crucial data for design validation and quality assurance.

To control quality, manufacturers implement rigorous procedures. This includes defining clear quality standards, conducting regular inspections at various production stages, and maintaining calibrated equipment for accurate testing. Statistical process control (SPC) techniques like control charts and process capability indices monitor production variability and ensure consistency.

Documentation and traceability are vital for tracking quality metrics and addressing any deviations promptly. Continuous improvement through feedback mechanisms and corrective actions helps in refining processes and reducing defects over time.

Overall, a robust quality control system integrates diverse testing methods with stringent process controls and continuous improvement initiatives to deliver mechanically sound and reliable parts.

Tips for Procurement and Considerations when Purchasing from mechanical part

When procuring mechanical parts, consider these essential tips to ensure efficiency and quality:

1. Specification Clarity: Clearly define technical requirements such as dimensions, material type, tolerances, and performance standards. This avoids ambiguity and ensures suppliers deliver precisely what you need.

2. Supplier Selection: Choose suppliers based on their experience, reputation, and ability to meet your specifications. Evaluate their track record, certifications, and quality control processes.

3. Cost vs. Quality: Balance between cost-effectiveness and quality. Cheaper options may compromise durability or performance, so prioritize suppliers who offer reasonable prices without sacrificing quality.

4. Lead Times and Logistics: Evaluate suppliers’ lead times and their ability to meet your project timelines. Factor in shipping logistics, especially if dealing with international suppliers.

5. Quality Assurance: Implement stringent quality assurance processes. Inspect incoming parts to ensure they meet specifications before acceptance, reducing the risk of defects impacting production.

6. Communication and Contracts: Maintain clear communication with suppliers throughout the procurement process. Establish contracts detailing specifications, delivery schedules, pricing, and terms to mitigate misunderstandings.

7. Supplier Relationships: Cultivate strong relationships with reliable suppliers. This fosters better collaboration, priority handling during shortages, and potential cost savings through long-term partnerships.

8. Risk Management: Identify potential risks such as supply chain disruptions or quality issues. Have contingency plans in place to mitigate these risks and maintain continuity of operations.

By adhering to these considerations, you can streamline the procurement of mechanical parts, ensuring they meet your project requirements efficiently and effectively.

FAQs on Sourcing and Manufacturing from mechanical part in China

FAQs on Sourcing and Manufacturing Mechanical Parts in China

1. Why source mechanical parts from China?

China offers competitive pricing, a wide range of manufacturers, advanced manufacturing technologies, and significant production capacity, making it a preferred destination for sourcing mechanical parts.

2. How do I find reliable suppliers in China?

Use platforms like Alibaba, Global Sources, and Made-in-China. Verify suppliers through site visits, audits, and requesting references. Employ third-party inspection services for added assurance.

3. What are the key considerations when selecting a manufacturer?

Consider factors like manufacturing capabilities, quality control processes, certifications (ISO 9001), lead times, and communication efficiency. Visit potential factories to assess their operations firsthand.

4. How do I ensure the quality of parts?

Define clear specifications and quality standards. Use detailed contracts and include quality assurance clauses. Conduct regular inspections and audits, and employ third-party quality control services.

5. What are the common payment terms?

Typical terms include a 30% deposit before production and 70% upon shipment. Letters of credit (LC) and escrow services offer additional security.

6. How can I protect my intellectual property (IP)?

Use Non-Disclosure Agreements (NDAs) and Non-Compete Clauses (NCCs). Register your patents and trademarks in China. Work with reputable manufacturers and limit the sharing of sensitive information.

7. What are the shipping and logistics considerations?

Choose between air freight for faster delivery or sea freight for cost-effectiveness. Consider Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight). Partner with reliable freight forwarders and customs brokers.

8. Are there any cultural differences to be aware of?

Building relationships (guanxi) is crucial. Be patient in negotiations, show respect, and be aware of holidays like Chinese New Year which can impact production schedules.

9. What legal regulations should I consider?

Familiarize yourself with Chinese manufacturing laws, import/export regulations, and tariffs. Ensure compliance with international standards relevant to your industry.

10. How do I handle communication barriers?

Use bilingual staff or translators. Establish clear and concise communication channels and document all agreements in writing to avoid misunderstandings.

By addressing these common questions, you can navigate the complexities of sourcing and manufacturing mechanical parts in China more effectively.