Technology and Applications of metal engraving machine laser

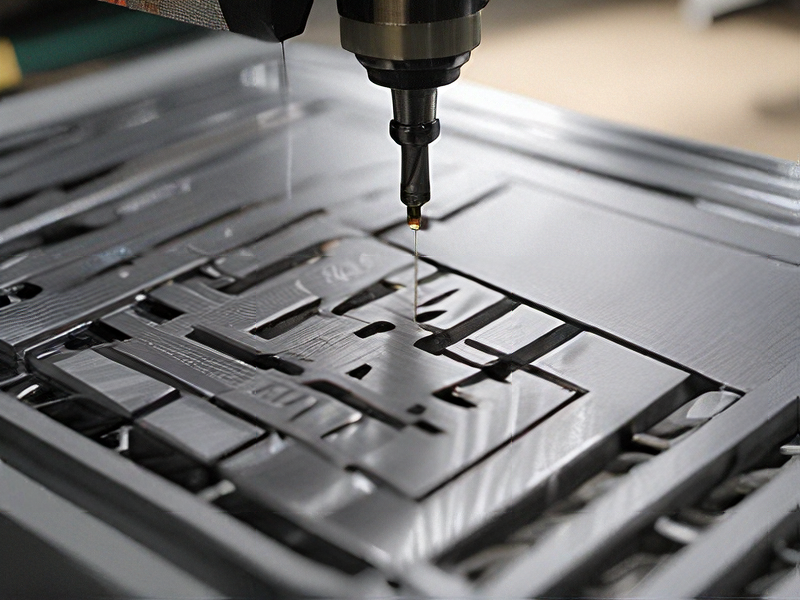

Metal engraving machines that utilize lasers offer precise and versatile capabilities across various applications. These machines employ high-powered lasers, typically CO2 or fiber lasers, to etch designs or markings onto metal surfaces with exceptional detail and accuracy.

Technology:

Metal engraving laser machines operate by focusing a concentrated beam of light onto the metal surface. CO2 lasers are effective for marking organic materials and some metals, using a wavelength absorbed well by materials like wood, plastics, and rubber. Fiber lasers are adept at engraving metals, using a fiber-optic cable to deliver a laser beam capable of marking a range of metals, with significant power and speed. The process involves the use of computer-aided design (CAD) software to create designs, which are then translated into instructions for the laser engraver to follow.

Applications:

1. Industrial Marking: Used extensively in manufacturing for part identification, serial numbers, and barcodes on metal components.

2. Jewelry Making: Enables intricate designs and personalization on metal jewelry pieces, enhancing craftsmanship and customization options.

3. Medical Instruments: Engraving medical devices with regulatory information, serial numbers, and logos for traceability and branding.

4. Aerospace and Automotive: Engraving on parts for identification, tracking, and aesthetic purposes, ensuring durability and readability under harsh conditions.

5. Gifts and Awards: Personalized gifts, trophies, and plaques benefit from the precision and customization capabilities of laser engraving.

These machines provide flexibility in engraving depth and speed, making them suitable for both industrial-scale production and small-scale artisanal work. They excel in creating permanent marks without compromising the integrity of the metal, offering durability and resistance to wear. As technology advances, these machines continue to evolve, incorporating features that enhance efficiency, ease of use, and broader compatibility with a variety of metal surfaces.

Quality Testing Methods for metal engraving machine laser and how to control quality

Quality testing for metal engraving laser machines involves various methods to ensure precision, consistency, and durability. Here’s a concise overview of key testing methods and quality control strategies:

Quality Testing Methods:

1. Visual Inspection: Check for visible defects such as scratches, inconsistencies, or irregular engravings.

2. Dimensional Accuracy: Use calipers and micrometers to measure the engraving dimensions against specifications.

3. Surface Roughness: Employ a profilometer to measure the surface roughness of the engraved area.

4. Laser Power and Focus Test: Utilize power meters and beam profilers to ensure the laser’s power output and focus are consistent.

5. Material Hardness Testing: Conduct hardness tests on the engraved areas to ensure the laser hasn’t altered the material properties.

6. Environmental Stress Testing: Expose engraved samples to various environmental conditions (humidity, temperature) to check for durability.

Quality Control Strategies:

1. Calibration: Regularly calibrate the laser machine to maintain accuracy.

2. Standard Operating Procedures (SOPs): Establish and follow SOPs for machine operation, maintenance, and testing processes.

3. Training: Ensure operators are well-trained in machine handling and quality inspection techniques.

4. Batch Testing: Perform quality tests on random samples from each batch of products to identify potential issues early.

5. Data Logging: Maintain detailed logs of machine settings, environmental conditions, and test results for traceability and analysis.

6. Feedback Loop: Implement a system for feedback from end-users and quality inspectors to continually improve processes and machine settings.

7. Preventive Maintenance: Schedule regular maintenance checks to prevent machine wear and tear, which can affect engraving quality.

By integrating these testing methods and quality control strategies, manufacturers can ensure their metal engraving laser machines produce high-quality, consistent, and durable engravings.

Tips for Procurement and Considerations when Purchasing from metal engraving machine laser

When procuring a metal engraving laser machine, it’s essential to consider several factors to ensure you make a well-informed decision that meets your needs. Here are some key tips and considerations:

Key Tips

1. Define Your Requirements:

– Identify the types of metals you will engrave, the thickness of the materials, and the complexity of designs.

– Consider the volume of work, whether for small batches or mass production.

2. Research and Compare:

– Investigate different models and brands, comparing their specifications, capabilities, and reviews.

– Check for features such as power output, precision, speed, and supported file formats.

3. Budget Wisely:

– Determine your budget, including the cost of the machine, maintenance, accessories, and potential software updates.

– Evaluate the cost-benefit ratio of different machines and consider long-term operational costs.

4. Vendor Reputation:

– Choose a reputable supplier with good customer service and support.

– Look for warranties and post-purchase support options, including training and troubleshooting.

5. Technology and Features:

– Opt for machines with advanced laser technology, such as fiber lasers, which offer high precision and durability.

– Consider additional features like rotary attachments for cylindrical objects or software for design customization.

Considerations

1. Safety:

– Ensure the machine complies with safety standards and includes safety features like protective enclosures and proper ventilation systems.

2. Maintenance and Support:

– Assess the ease of maintenance and availability of spare parts.

– Verify if the supplier offers technical support and training for your team.

3. Software Compatibility:

– Ensure the machine’s software is compatible with your existing systems and supports the file formats you use.

– Look for user-friendly software that allows easy design and customization.

4. Scalability:

– Consider if the machine can handle future increases in production demand or if it can be upgraded with additional features.

5. Energy Consumption:

– Evaluate the energy efficiency of the machine to minimize operational costs and environmental impact.

By thoroughly assessing these factors, you can select a metal engraving laser machine that meets your operational needs and provides long-term value.

FAQs on Sourcing and Manufacturing from metal engraving machine laser in China

FAQs on Sourcing and Manufacturing Metal Engraving Laser Machines in China

1. Why source metal engraving laser machines from China?

China is a leading hub for manufacturing metal engraving laser machines due to its advanced technology, competitive pricing, and extensive production capacity. Chinese manufacturers offer a wide range of options tailored to different industrial needs.

2. How to find reliable suppliers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Look for suppliers with high ratings, positive reviews, and verified certifications. It’s beneficial to request samples and visit factories if possible.

3. What certifications should I look for?

Ensure the supplier has ISO 9001 for quality management and CE marking for European standards. Other important certifications might include RoHS for environmental compliance and FDA for laser safety.

4. What are the typical lead times?

Lead times vary by manufacturer and order size, typically ranging from 2 to 6 weeks. Customizations may extend this period.

5. How to handle quality control?

Implement a quality control process, including pre-shipment inspections and third-party audits. Request detailed documentation and testing reports to verify the machine’s performance.

6. What about shipping and logistics?

Choose a reliable freight forwarder experienced in handling machinery. Consider shipping options like FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Ensure proper packaging to prevent damage during transit.

7. Are there any import duties or taxes?

Import duties and taxes depend on your country’s regulations. Check with local customs offices or a customs broker to understand applicable fees.

8. How does after-sales support work?

Ensure the supplier offers robust after-sales support, including technical assistance, spare parts, and warranty services. Verify the availability of remote troubleshooting and local service centers.

9. What are the payment terms?

Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and escrow services. Negotiate terms that protect your interests, such as partial payments upon delivery.

10. How to handle language barriers and communication?

Many Chinese suppliers have English-speaking representatives. Use clear, concise communication and confirm all details in writing to avoid misunderstandings.