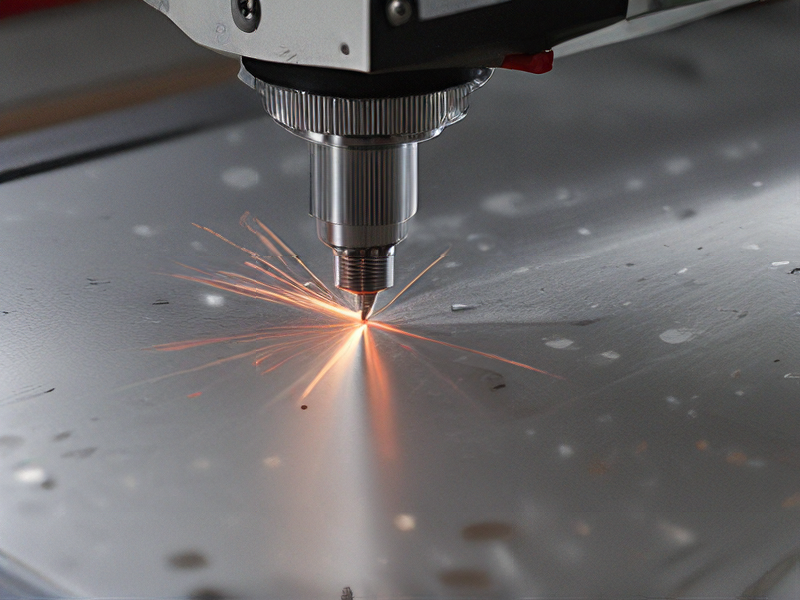

Technology and Applications of metal laser cutters

Metal laser cutters are advanced tools used in various industries for precise cutting of metals using laser technology. They utilize high-powered lasers to melt, burn, or vaporize material along a predetermined path, guided by computer numerical control (CNC) systems. The key applications of metal laser cutters span several industries:

1. Manufacturing: In manufacturing, laser cutters are essential for creating intricate metal components with high accuracy and repeatability. They are used in the production of automotive parts, aerospace components, machinery, and electronics.

2. Prototyping and Rapid Manufacturing: Metal laser cutters enable rapid prototyping by quickly producing complex parts without the need for expensive tooling. This flexibility is crucial in product development and customization.

3. Art and Architecture: Artists and architects utilize laser cutters to create detailed metal sculptures, decorative elements, and structural components. The precision of laser cutting allows for intricate designs and patterns.

4. Medical and Dental: In medical device manufacturing, laser cutters are used to produce fine surgical instruments, implants, and components for medical equipment. In dentistry, they create dental prosthetics and appliances.

5. Jewelry Making: Laser cutters are employed in the jewelry industry to cut intricate designs in metals like gold, silver, and platinum. They enable precise detailing and customization in jewelry manufacturing.

6. Electronics: Metal laser cutters produce precise components for electronic devices, including housings, connectors, and shielding components. Their accuracy is crucial for maintaining the functionality and reliability of electronic products.

Technological advancements in laser cutting machines continue to enhance their capabilities, such as increased cutting speeds, improved edge quality, and compatibility with a wider range of metals. These advancements drive their adoption across industries, offering efficient solutions for complex metal cutting challenges.

Quality Testing Methods for metal laser cutters and how to control quality

Quality testing methods for metal laser cutters typically include:

1. Dimensional Inspection: Using precise measurement tools like calipers or coordinate measuring machines (CMM) to verify dimensions against specifications.

2. Visual Inspection: Examining cut edges for burrs, dross (residual material), and overall cut quality to ensure they meet visual standards.

3. Surface Roughness Measurement: Assessing the surface finish using profilometers to ensure it meets required smoothness levels.

4. Material Testing: Conducting tests like hardness testing (Rockwell or Vickers) to verify material integrity after cutting.

5. Edge Quality Assessment: Evaluating edge sharpness and consistency, often using microscopy or edge profiling tools.

To control quality effectively:

– Establish Standards: Define clear quality criteria for dimensions, surface finish, and edge quality.

– Regular Calibration: Ensure laser cutters are regularly calibrated for accuracy and consistency.

– Operator Training: Train operators in proper machine operation, maintenance, and quality inspection techniques.

– Process Monitoring: Implement real-time monitoring of cutting parameters (power, speed, gas pressure) to detect deviations.

– Feedback Loops: Use feedback from inspections to continuously improve processes and prevent defects.

By employing these methods and controls, manufacturers can ensure consistent and high-quality outputs from their metal laser cutting operations.

Tips for Procurement and Considerations when Purchasing from metal laser cutters

When purchasing from metal laser cutters, consider these key tips and considerations:

1. Capabilities and Specializations: Evaluate the cutter’s capabilities, such as the range of materials they handle (aluminum, stainless steel, etc.) and their maximum cutting thickness. Ensure they specialize in the type of metal and thickness you require.

2. Quality Assurance: Inquire about their quality control measures and certifications (ISO, AS9100, etc.). This ensures consistent quality and adherence to industry standards.

3. Technology and Equipment: Check the type of laser cutting technology they use (CO2, fiber, etc.) and the age/condition of their equipment. Modern equipment typically offers higher precision and efficiency.

4. Experience and Reputation: Assess their experience in handling projects similar to yours. Look for reviews, testimonials, or case studies to gauge their reputation and reliability.

5. Customization and Design Support: Determine if they offer design assistance or CAD/CAM services. This can streamline the manufacturing process and ensure compatibility with their equipment.

6. Lead Times and Flexibility: Understand their lead times and production capabilities. Flexibility in handling rush orders or accommodating changes can be crucial for meeting project deadlines.

7. Cost and Value: Compare pricing structures, but also consider overall value including quality, service, and reliability. Cheaper isn’t always better if it compromises on these factors.

8. Logistics and Shipping: Discuss logistics, shipping options, and packaging methods to ensure your products arrive safely and on time.

9. Environmental and Ethical Considerations: Inquire about their sustainability practices and adherence to ethical standards in sourcing materials and labor.

10. Communication and Support: Clear communication channels and responsive customer support are essential for addressing issues promptly and ensuring a smooth purchasing experience.

By considering these factors, you can make an informed decision when selecting a metal laser cutter that meets your specific procurement needs and requirements.

FAQs on Sourcing and Manufacturing from metal laser cutters in China

FAQs on Sourcing and Manufacturing from Metal Laser Cutters in China

1. Why source metal laser cutters from China?

– Cost-Effectiveness: Chinese manufacturers often offer competitive pricing.

– Advanced Technology: Many Chinese firms use state-of-the-art laser cutting technology.

– Customization: Chinese manufacturers can provide tailored solutions to meet specific requirements.

2. How to find reliable suppliers?

– Online Platforms: Websites like Alibaba, Made-in-China, and Global Sources.

– Trade Shows: Attend exhibitions like the Canton Fair and CIIF.

– Third-Party Agencies: Use sourcing agents for vetting suppliers.

3. What should I consider when selecting a manufacturer?

– Reputation: Check reviews and ratings.

– Certifications: Ensure the supplier has relevant ISO certifications.

– Production Capacity: Verify their ability to meet your order size and deadlines.

– Quality Control: Inquire about their quality assurance processes.

4. How do I verify the quality of the products?

– Sample Testing: Request samples before placing large orders.

– Third-Party Inspection: Hire independent inspection services.

– Factory Audits: Conduct on-site visits to assess facilities.

5. What are the common payment terms?

– Initial Deposit: Typically, 30% upfront.

– Balance Payment: Remaining 70% upon shipment or after product inspection.

– Letters of Credit (LC): Used for larger orders to ensure payment security.

6. How can I ensure timely delivery?

– Clear Contracts: Include delivery timelines in the agreement.

– Regular Communication: Maintain frequent updates with the supplier.

– Penalties for Delays: Specify penalties for late delivery in the contract.

7. What logistics considerations are there?

– Shipping Options: Choose between air, sea, or rail depending on urgency and cost.

– Customs Clearance: Ensure all paperwork is in order to avoid delays.

– Freight Forwarders: Consider using a professional freight forwarder to manage logistics.

8. Are there any cultural or language barriers?

– Language Services: Many suppliers offer English-speaking staff.

– Cultural Sensitivity: Understand and respect Chinese business etiquette for smoother negotiations.

By addressing these FAQs, businesses can navigate the complexities of sourcing and manufacturing with metal laser cutters in China more effectively.