Discover

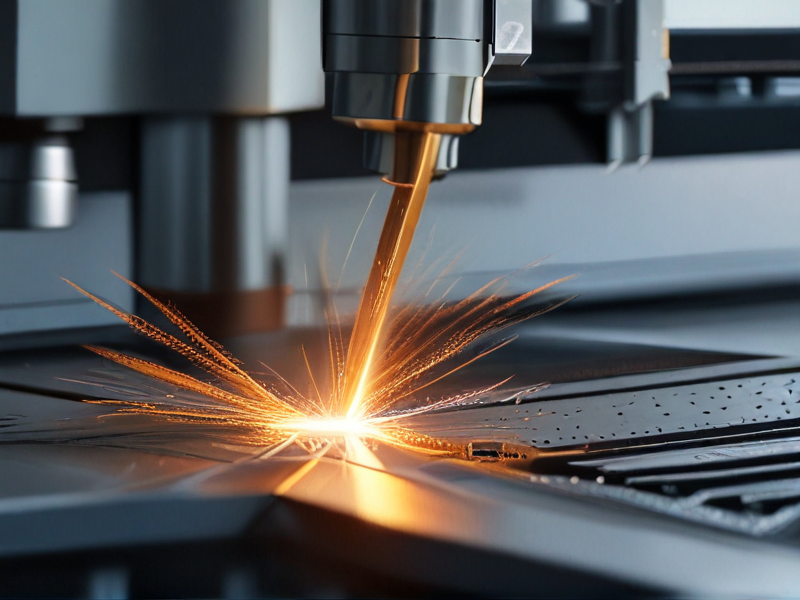

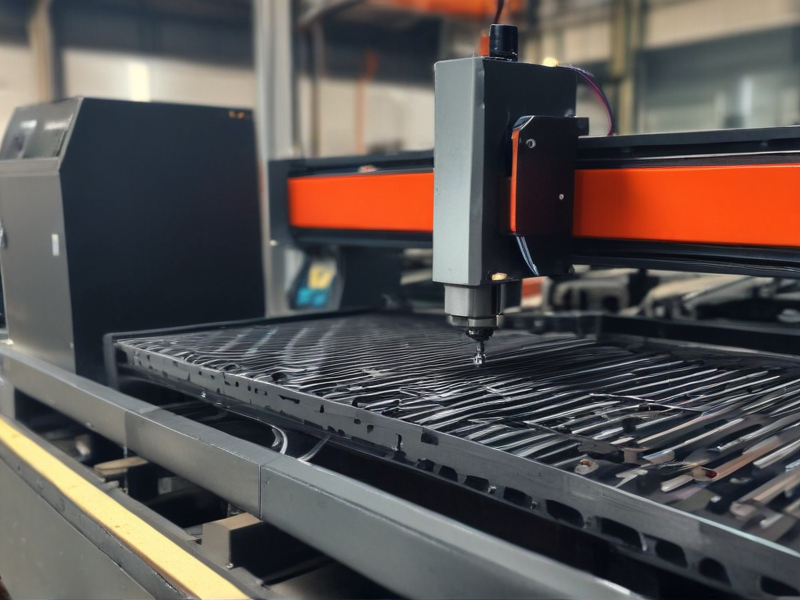

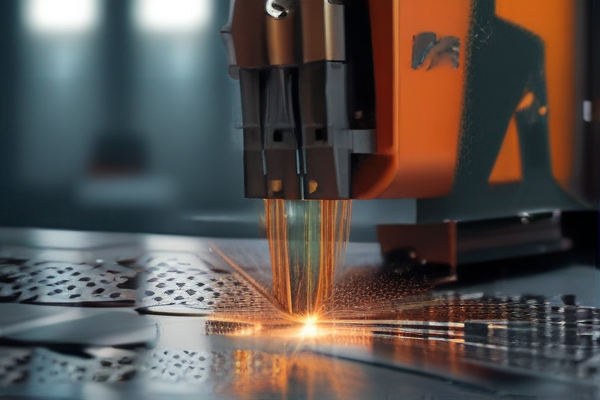

Reliable Metal Laser Cutting Machines from SourcifyChina Factory: Quality and Precision Guaranteed

—

When it comes to sourcing high-quality metal laser cutting machines, SourcifyChina Factory stands out as a reliable and reputable supplier. With years of experience in the industry, they offer a range of cutting-edge machines designed to meet the diverse needs of businesses worldwide.

SourcifyChina Factory is committed to delivering precision, efficiency, and durability in every product. Their metal laser cutting machines are equipped with advanced technology, ensuring accurate and clean cuts, which are essential for various industrial applications. Whether you are in automotive, aerospace, or any other sector requiring metal fabrication, their machines can significantly enhance your production capabilities.

One of the key benefits of choosing SourcifyChina Factory is their rigorous quality control process. Every machine undergoes thorough testing to ensure it meets international standards and performs reliably in demanding environments. Additionally, the factory offers excellent customer support, assisting with installation, maintenance, and troubleshooting to ensure seamless operation.

Furthermore, SourcifyChina Factory provides customization options to cater to specific requirements, making them a versatile choice for businesses of all sizes. Their competitive pricing, combined with exceptional quality, makes them a preferred partner for many companies looking to upgrade their manufacturing processes.

In summary, if you are in the market for reliable metal laser cutting machines, SourcifyChina Factory should be at the top of your list. Their commitment to quality, precision, and customer satisfaction sets them apart in the industry, providing you with the tools needed to achieve optimal production results.

Why Choose “SourcifyChina” Factory for Purchasing Metal Laser Cutting Machines from China?

SourcifyChina offers high-quality metal laser cutting machines that meet international standards. Their advanced technology ensures precision and efficiency in every cut, making them a reliable choice for buyers.

The factory provides competitive pricing without compromising on quality. This cost-effectiveness allows buyers to maximize their budget while still obtaining top-tier equipment.

With a strong focus on customer service, SourcifyChina offers comprehensive support throughout the purchasing process. From initial consultation to after-sales service, buyers receive expert guidance and assistance.

SourcifyChina’s extensive experience in the industry guarantees that they understand market needs and trends. Their expertise translates into products that are both innovative and reliable, meeting diverse industrial requirements.

The factory also emphasizes strict quality control measures. Every machine undergoes rigorous testing to ensure it meets the highest standards of performance and durability before delivery to customers.

In addition, SourcifyChina offers customization options to tailor machines according to specific buyer needs. This flexibility allows for optimal integration of the equipment into various production environments.

Choosing SourcifyChina means partnering with a factory committed to sustainable practices. They utilize environmentally friendly manufacturing processes, reducing their carbon footprint while delivering exceptional products.

The factory’s strong logistics network ensures timely delivery to international destinations. Buyers can rely on efficient shipping processes that minimize delays and ensure their machines arrive in excellent condition.

SourcifyChina also provides comprehensive training for operating their laser cutting machines. This support helps buyers quickly adapt to new technology, enhancing productivity and ensuring safe operation.

In conclusion, SourcifyChina stands out as a premier choice for purchasing metal laser cutting machines from China. Their commitment to quality, customer service, and innovation makes them a preferred partner for businesses worldwide seeking reliable and efficient manufacturing solutions.

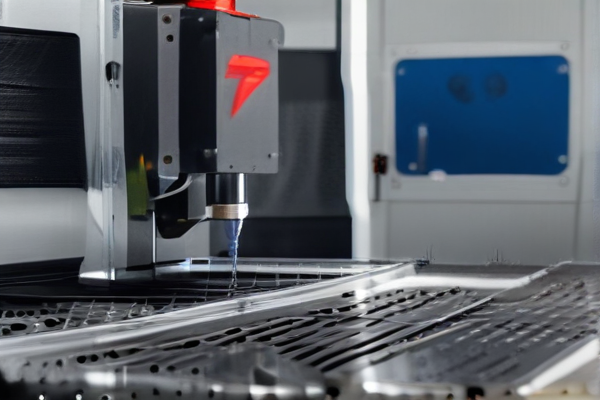

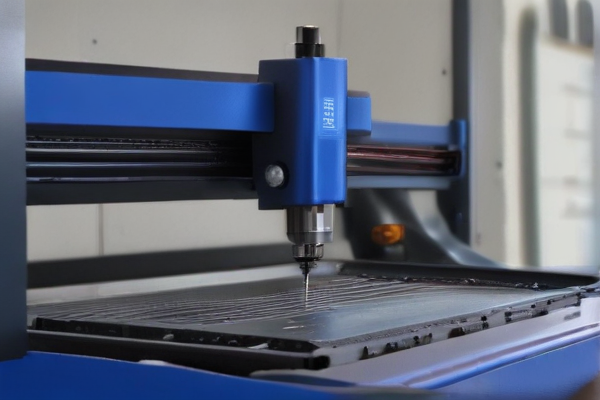

Metal laser cutting machines are essential for precise and efficient cutting of various metals. They come in different types, each suited for specific applications and materials.

– Fiber Laser Cutting Machines: These are known for their high efficiency and precision, suitable for cutting thin to thick metals such as stainless steel, carbon steel, aluminum, and brass.

– CO2 Laser Cutting Machines: These machines are versatile and can cut non-metal materials as well. They are ideal for cutting thicker materials but are generally slower compared to fiber lasers.

– Nd:YAG Laser Cutting Machines: These are less common but used for high-power applications. They are suitable for cutting thicker metals and are often used in automotive and aerospace industries.

– Hybrid Laser Cutting Machines: Combining the benefits of fiber and CO2 lasers, these machines offer flexibility and efficiency for various cutting tasks.

Key

Options and Features:

– Power Output: Determines the machine’s ability to cut through different thicknesses of metal. Common ranges are from 500W to over 10kW.

– Cutting Speed: Influences productivity; higher-powered machines generally offer faster cutting speeds.

– Precision and Accuracy: Essential for detailed and intricate designs, often measured in micrometers.

– Automation and CNC Control: Advanced machines come with computer numerical control (CNC) for automated cutting, improving precision and efficiency.

– Cooling Systems: Prevent overheating and maintain machine efficiency. Options include water-cooled and air-cooled systems.

– Material Compatibility: Ensures the machine can handle the specific types of metal you need to cut.

– Maintenance and Durability: Consider machines with lower maintenance needs and longer lifespans for cost-effectiveness.

– Software Integration: Advanced machines offer compatibility with CAD/CAM software for better design and cutting capabilities.

Choosing the right metal laser cutting machine depends on your specific needs, including the type of metal, thickness, production volume, and desired precision.

Metal laser cutting machines are revolutionizing various industries by providing precise, efficient, and versatile cutting solutions. These machines use focused laser beams to cut, engrave, and shape metal sheets, offering numerous applications across different sectors.

– Manufacturing: Ideal for cutting intricate parts and components, enhancing production speed and precision.

– Automotive Industry: Used for cutting car parts, body panels, and intricate designs, improving overall vehicle design and safety.

– Aerospace: Essential for fabricating complex aircraft components, ensuring high precision and durability.

– Construction: Employed in cutting structural components, beams, and metal frames, ensuring accurate and clean cuts.

– Medical Devices: Utilized for producing surgical instruments and implants with high precision and minimal material wastage.

– Art and Design: Enables artists and designers to create detailed metal sculptures, jewelry, and custom pieces.

– Electronics: Facilitates the production of precise metal casings and components for various electronic devices.

– Metal Fabrication Shops: Enhances capabilities for custom metalwork, from prototypes to final products.

Metal laser cutting machines are integral to modern manufacturing, offering unparalleled precision and versatility across a wide range of applications.

Metal laser cutting machines have revolutionized manufacturing in the aerospace, defense, and marine sectors, providing unmatched precision, efficiency, and versatility. In aerospace, these machines are crucial for producing complex components from high-strength materials such as titanium and Inconel. The ability to achieve tight tolerances and intricate geometries ensures that parts meet stringent safety and performance standards. Additionally, laser cutting reduces material waste and minimizes thermal distortion, which is critical for maintaining the integrity of thin-walled structures and aerodynamic surfaces.

In the defense and marine industries, metal laser cutting machines play a pivotal role in fabricating robust and reliable components. For defense applications, these machines can produce armor plating, vehicle parts, and weapon system components with exceptional accuracy and repeatability. This precision is vital for ensuring the effectiveness and durability of defense equipment under harsh conditions. In the marine sector, laser cutting is used to create hulls, frames, and other structural elements from corrosion-resistant metals like stainless steel and aluminum. The high-speed cutting capabilities and flexibility in handling various thicknesses make laser cutting an indispensable tool for shipbuilding and repair, enhancing both production efficiency and the longevity of marine vessels.

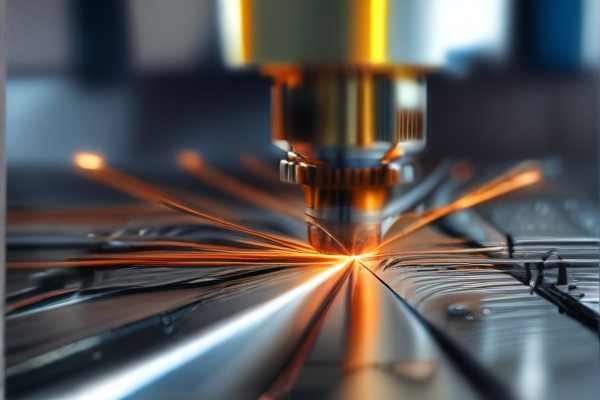

Metal laser cutting machines are revolutionizing the automotive industry by enhancing precision and efficiency in manufacturing processes. These machines use high-powered lasers to cut through various metals with remarkable accuracy, allowing for the production of intricate parts that are essential in modern vehicles. Automotive components such as chassis, engine parts, and intricate body designs benefit greatly from laser cutting due to its ability to produce clean, precise edges and complex shapes without the need for additional finishing. This technology reduces material waste, speeds up production times, and ensures consistent quality, all of which are crucial for meeting the high standards and demands of the automotive market.

In the electronics industry, metal laser cutting machines play a pivotal role in the fabrication of delicate and precise components. As electronic devices become increasingly compact and complex, the need for highly accurate cutting solutions grows. Laser cutting machines provide the precision required to produce small, intricate parts for circuit boards, connectors, and enclosures. The ability to cut with minimal thermal distortion ensures that the integrity of electronic components is maintained, which is critical for the performance and reliability of the final product. Additionally, the flexibility of laser cutting allows manufacturers to quickly adapt to design changes, facilitating rapid prototyping and innovation in the fast-paced electronics sector.

Metal laser cutting machines are revolutionizing the construction industry by enhancing precision and efficiency in cutting metal components. These machines utilize high-powered lasers to cut through various types of metal with remarkable accuracy, reducing material waste and enabling the creation of complex geometrical shapes that would be challenging with traditional cutting methods. The precise cuts provided by laser technology lead to cleaner edges, reducing the need for further processing and thereby speeding up the construction process. Additionally, the automation capabilities of modern laser cutting machines contribute to improved safety on construction sites by minimizing the need for manual handling of cutting tools.

In the energy sector, metal laser cutting machines play a critical role in the manufacturing of components for renewable energy systems such as wind turbines, solar panels, and fuel cells. The precision and speed of laser cutting technology allow for the efficient production of high-quality parts, which is essential for the performance and longevity of energy systems. For instance, in the production of wind turbines, laser cutting ensures that each blade is cut with exact dimensions, contributing to the overall aerodynamic efficiency of the turbine. Similarly, in solar panel manufacturing, laser cutting enables the precise shaping of metal frames and supports, enhancing the structural integrity and durability of the panels. By improving the manufacturing process, metal laser cutting machines help drive advancements in energy technology and contribute to the development of more efficient and sustainable energy solutions.

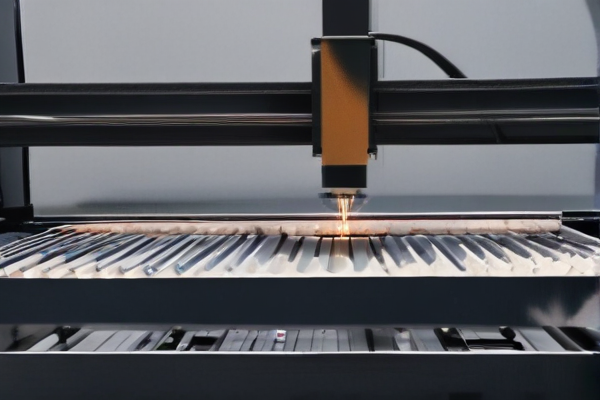

Metal laser cutting machines represent the ultimate advancement in precision engineering for the industrial sector. These machines utilize high-powered lasers to slice through metal with unparalleled accuracy and efficiency, making them indispensable in manufacturing and fabrication industries. The laser technology, typically involving CO2, fiber, or crystal lasers, enables precise cutting of various metals such as steel, aluminum, and titanium. One of the most remarkable features of metal laser cutting machines is their ability to produce complex shapes and intricate designs with minimal material waste, significantly enhancing production efficiency and reducing costs.

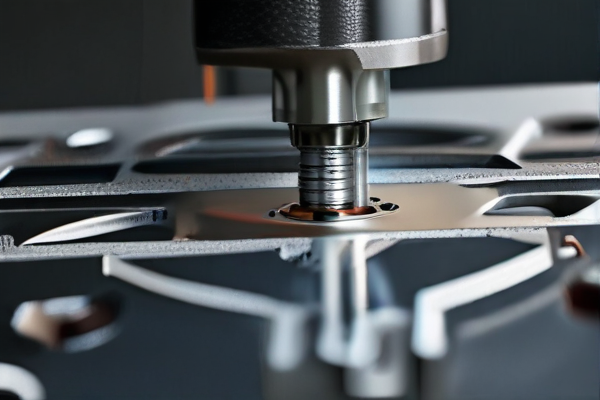

In addition to precision and efficiency, metal laser cutting machines offer incredible versatility and automation capabilities. Modern systems often integrate with computer numerical control (CNC) systems, allowing for detailed programming and automated operations, which reduce the need for manual intervention. This automation ensures consistent quality and repeatability in mass production settings. Moreover, the non-contact nature of laser cutting minimizes the risk of material contamination and deformation, which is critical for maintaining the integrity of high-tolerance components. The ultimate combination of speed, precision, and versatility makes metal laser cutting machines a cornerstone of modern industrial equipment, driving advancements across various sectors from automotive to aerospace.

Metal laser cutting machines are essential tools in the medical device industry, providing unmatched precision and efficiency. These machines utilize high-powered lasers to cut and shape metal components with extreme accuracy, crucial for producing intricate and delicate parts used in medical devices. The precision of laser cutting ensures that parts meet the strict tolerances required for medical applications, such as surgical instruments, implants, and diagnostic equipment. This level of accuracy is vital for ensuring the functionality and safety of medical devices, where even the smallest deviation can lead to significant performance issues.

Moreover, metal laser cutting machines offer significant advantages in terms of speed and versatility. They can quickly process a wide range of metals, including stainless steel, titanium, and various alloys, which are commonly used in the medical field due to their biocompatibility and durability. The ability to efficiently produce complex geometries and fine features without the need for additional tooling or processing steps reduces production time and costs. Additionally, the non-contact nature of laser cutting minimizes the risk of contamination and mechanical stress on the materials, maintaining the integrity and cleanliness required for medical devices. This combination of precision, speed, and versatility makes metal laser cutting machines an indispensable asset in the manufacturing of high-quality medical devices.

Metal laser cutting machines have revolutionized modern machining and manufacturing processes with their precision and efficiency. These machines utilize high-powered lasers focused through optics to melt, burn, or vaporize material along a predetermined path. This method allows for intricate designs and complex shapes to be cut from various metals with minimal material waste. The precision of laser cutting ensures tight tolerances and smooth finishes, making it ideal for industries where quality and accuracy are paramount, such as aerospace, automotive, and electronics. Additionally, the speed of laser cutting significantly reduces production times compared to traditional methods, enhancing overall productivity and cost-effectiveness.

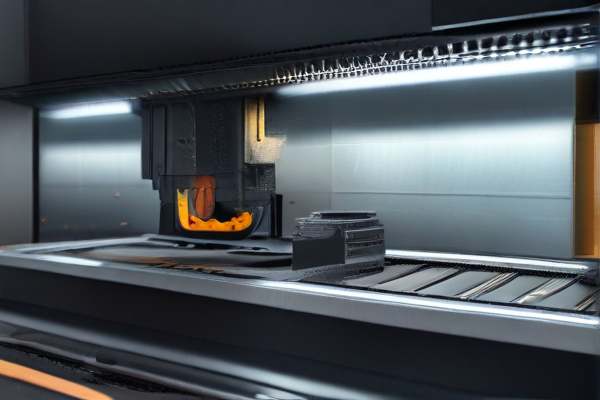

In terms of technology, metal laser cutting machines come in several types, including CO2 lasers and fiber lasers, each suited for different applications. CO2 lasers are versatile and work well with non-metal materials, while fiber lasers excel in cutting metals like steel, aluminum, and copper with exceptional speed and precision. Advancements in laser technology have also led to the development of hybrid machines combining laser cutting with other machining processes like milling and drilling, further expanding their capabilities. As the demand for more intricate and precise components grows across industries, metal laser cutting machines continue to evolve, offering manufacturers unparalleled flexibility and efficiency in their production processes.

SourcifyChina’s metal laser cutting machines are crafted from high-quality, durable materials designed to withstand rigorous industrial use. The main structure typically uses reinforced steel, ensuring stability and precision during operation. The cutting bed is often made from cast iron, providing a sturdy and vibration-resistant platform for cutting.

The laser sources, crucial to these machines, are constructed using advanced fiber optics, known for their efficiency and longevity. Protective glass shields are incorporated to safeguard users from laser exposure, emphasizing safety in design. These materials collectively ensure reliability, precision, and durability.

In conclusion, SourcifyChina’s metal laser cutting machines utilize a combination of reinforced steel, cast iron, advanced fiber optics, and protective glass, ensuring optimal performance and safety. This robust construction guarantees these machines meet the high standards required for industrial applications.

SourcifyChina employs stringent quality control measures in the manufacturing of their metal laser cutting machines. The process begins with the careful selection of raw materials, ensuring they meet high standards for durability and performance.

Once materials are sourced, they undergo rigorous testing to confirm their suitability. This includes stress tests and chemical analyses, ensuring they can withstand the demands of laser cutting operations without compromising quality.

During production, SourcifyChina implements continuous monitoring and inspection at each stage. Advanced machinery and skilled technicians work together to maintain precision and consistency in every component and assembly.

Each metal laser cutting machine is subjected to a series of functional tests before it leaves the factory. These tests simulate real-world conditions to ensure the machines operate flawlessly under various scenarios.

Final inspections include detailed reviews of the machine’s cutting accuracy, speed, and overall performance. Any deviations from the expected standards are corrected immediately, ensuring only top-quality machines reach the customers.

SourcifyChina also maintains a feedback loop with customers to continually improve their quality control processes. Customer feedback is analyzed to identify potential areas of enhancement, leading to continuous product improvements and customer satisfaction.

The commitment to quality control at SourcifyChina is evident in their comprehensive approach, from raw material selection to final product testing, ensuring their metal laser cutting machines are reliable, efficient, and of the highest quality.

SourcifyChina’s metal laser cutting machines boast precision and efficiency, enabling clean and accurate cuts for various metal types. These machines use advanced laser technology, reducing waste and improving production speed. Their versatility supports cutting through steel, aluminum, and other metals with ease, making them ideal for diverse industrial applications.

Equipped with user-friendly interfaces, SourcifyChina’s laser cutting machines offer intuitive controls and easy operation, minimizing the learning curve for operators. The machines are designed for durability, ensuring long-term, reliable performance even in demanding environments. Additionally, their robust construction ensures minimal maintenance requirements, enhancing overall productivity.

These machines integrate cutting-edge safety features to protect operators during use, including emergency stop functions and protective enclosures. This focus on safety helps to maintain a secure working environment. Furthermore, SourcifyChina provides comprehensive customer support, including training and troubleshooting, ensuring users can maximize the potential of their laser cutting equipment.

In conclusion, SourcifyChina’s metal laser cutting machines deliver high precision, efficiency, and safety, making them a valuable asset for any metalworking operation. Their advanced features and robust construction ensure they can handle various cutting tasks with ease, contributing to enhanced productivity and reduced operational costs.

Metal laser cutting machines offer unparalleled precision and efficiency, making them essential in modern manufacturing and metalworking.

– High Precision: Laser cutting machines deliver highly accurate cuts with minimal tolerances, ensuring exact specifications are met.

– Speed and Efficiency: These machines can cut through metal at high speeds, significantly reducing production time and increasing throughput.

– Versatility: Capable of cutting various metals, including steel, aluminum, and copper, laser cutters are adaptable to different project requirements.

– Quality of Cut: The clean edges produced by laser cutting reduce the need for additional finishing processes, saving time and resources.

– Automation and Integration: Many laser cutting machines can be integrated with CAD/CAM software for automated operations, enhancing productivity and consistency.

– Material Utilization: Laser cutting optimizes material use, reducing waste and cost, which is economically beneficial for large-scale production.

– Safety and Clean Operation: Laser cutting is a non-contact process, minimizing the risk of injury and contamination, and often includes features to manage fumes and debris.

– Reduced Maintenance: Compared to traditional cutting tools, laser cutters require less maintenance, ensuring lower downtime and long-term cost savings.

Overall, metal laser cutting machines are a vital investment for industries aiming to enhance their manufacturing capabilities with high precision, speed, and efficiency.

Metal laser cutting machines are renowned for their precision, efficiency, and versatility in manufacturing and fabrication. Here are some key features:

– High Precision: Laser cutting machines can achieve extremely fine and detailed cuts, with tolerances as tight as 0.1 mm, making them ideal for intricate designs.

– Speed: These machines offer fast cutting speeds, which significantly reduce production times and increase throughput.

– Versatility: Capable of cutting various metals, including steel, aluminum, brass, and copper, laser cutters are suitable for a wide range of applications.

– Automation: Modern laser cutters often feature automated loading and unloading systems, reducing manual labor and increasing productivity.

– Low Heat Affected Zone (HAZ): The laser cutting process minimizes the heat-affected zone, reducing thermal distortion and maintaining the integrity of the material.

– Clean Cuts: The precision of laser cutting results in clean, burr-free edges, minimizing the need for secondary finishing processes.

– Energy Efficiency: Advances in laser technology have made these machines more energy-efficient, reducing operational costs and environmental impact.

– Software Integration: Many laser cutting machines are equipped with advanced software for CAD/CAM integration, enabling easy design modifications and efficient workflow management.

– Safety Features: Equipped with enclosures and safety interlocks, laser cutting machines ensure a safe working environment for operators.

– Maintenance: While maintenance requirements exist, modern machines are designed for easier upkeep with features like self-cleaning nozzles and automated diagnostics.

These features collectively make metal laser cutting machines an essential tool in modern manufacturing, offering unmatched precision, efficiency, and flexibility.

SourcifyChina specializes in custom metal laser cutting machines, providing precision and efficiency for diverse projects. Their advanced technology ensures high-quality cuts for various metal types and thicknesses.

With a focus on customization, SourcifyChina tailors their machines to meet specific project requirements, enhancing productivity and reducing waste. They support industries ranging from automotive to aerospace, delivering reliable and durable solutions.

SourcifyChina’s commitment to innovation drives continuous improvement in their laser cutting machines, integrating the latest advancements for optimal performance. Their dedicated team offers expert support and training, ensuring seamless integration and operation.

Projects completed using SourcifyChina’s machines include intricate designs, complex components, and large-scale productions, demonstrating versatility and precision. Clients benefit from their extensive experience and dedication to quality, ensuring successful outcomes for every project.

In conclusion, SourcifyChina stands out for their custom metal laser cutting machines, catering to varied industry needs with precision, efficiency, and reliability. Their innovative approach and expert support make them a trusted partner for all metal cutting requirements, ensuring excellence in every project they undertake.

SourcifyChina is a prominent player in the metal laser cutting machine industry, known for its high-quality, innovative solutions tailored to meet the diverse needs of its global clientele. With a strong focus on precision and efficiency, SourcifyChina offers a range of state-of-the-art laser cutting machines that cater to various industrial applications, from automotive and aerospace to construction and manufacturing. Their machines are equipped with advanced features such as high-speed cutting, exceptional accuracy, and user-friendly interfaces, making them ideal for both large-scale production and intricate custom work. Additionally, SourcifyChina is committed to customer satisfaction, providing comprehensive after-sales support, including installation, training, and maintenance services. This dedication to quality and service has established SourcifyChina as a trusted name in the laser cutting market, driving innovation and excellence in the metalworking industry.

Metal laser cutting machines are pivotal in the aerospace industry due to their ability to achieve high precision and efficiency in cutting complex shapes and materials. Aircraft components, which require exact tolerances and intricate designs, benefit significantly from laser cutting technology. This technology ensures minimal material wastage and reduces the need for secondary processing, thereby improving overall production speed and cost-efficiency. Additionally, laser cutting supports the use of lightweight yet strong materials like titanium and aluminum, essential for aircraft structures and parts, ultimately enhancing performance and fuel efficiency.

In the defense and marine sectors, metal laser cutting machines play a crucial role in fabricating parts for vehicles, vessels, and weapon systems. The ability to cut through thick and hardened materials with high accuracy is indispensable for creating durable armor, hulls, and structural components. Laser cutting also facilitates rapid prototyping and customization of parts, which is vital in adapting to evolving defense needs and technological advancements. For marine applications, the precision of laser cutting helps in producing parts that withstand harsh marine environments, ensuring longevity and reliability. Overall, the integration of metal laser cutting machines in these industries enhances production capabilities, ensures superior quality, and supports the development of advanced, resilient equipment.

Metal laser cutting machines have revolutionized the automotive industry by enhancing precision and efficiency in manufacturing. These machines enable the production of complex and precise parts, such as engine components, body panels, and intricate designs on the chassis. The high accuracy and repeatability of laser cutting reduce material waste and ensure consistent quality, which is crucial in automotive manufacturing. Additionally, the flexibility of laser cutting allows for rapid prototyping and customization, which is essential for developing new models and designs. This technology also supports the lightweighting trend in the automotive sector by enabling the use of advanced materials like aluminum and high-strength steel, which are more challenging to cut with traditional methods.

In the electronics industry, metal laser cutting machines play a pivotal role in the production of various components, from circuit boards to enclosures for electronic devices. The precision of laser cutting is particularly beneficial for creating the fine, intricate patterns required on printed circuit boards (PCBs). This precision ensures the reliability and performance of electronic devices. Furthermore, laser cutting allows for the efficient production of metal enclosures and casings, which provide essential protection for electronic components. The ability to cut complex shapes and designs quickly and accurately enables manufacturers to meet the ever-growing demand for miniaturization and high-density packing in electronic devices. Overall, metal laser cutting technology is indispensable for maintaining the high standards and rapid pace of innovation in the electronics industry.

In the construction industry, metal laser cutting machines play a crucial role in enhancing precision, speed, and efficiency. These machines are instrumental in fabricating components for buildings, bridges, and other structures by cutting through various metals with high accuracy. The ability to cut complex shapes and intricate designs allows for more innovative architectural solutions and customized structural elements. Moreover, the precision of laser cutting reduces material wastage, ensuring cost-effective operations. This technology is also beneficial for prefabrication, where components are produced off-site with exact specifications, streamlining the construction process and reducing on-site assembly time.

In the energy sector, metal laser cutting machines are pivotal in the manufacturing and maintenance of equipment used in power generation, distribution, and storage. For instance, in the production of wind turbines, solar panels, and nuclear reactors, the high precision of laser cutting ensures the components meet stringent quality standards. This precision is essential for the efficiency and safety of energy systems. Additionally, laser cutting is used to produce parts for pipelines and other infrastructure in the oil and gas industry, where durability and exact fit are critical. The ability to quickly produce and repair components reduces downtime and enhances the overall reliability of energy systems, contributing to more sustainable energy solutions.

Metal laser cutting machines have revolutionized the industrial equipment sector, providing unparalleled precision and efficiency in cutting a variety of metals. These machines utilize a focused laser beam to melt, burn, or vaporize metal, allowing for intricate designs and complex shapes to be cut with minimal waste. Industries such as automotive, aerospace, and heavy machinery heavily rely on laser cutting technology for producing components with tight tolerances and superior edge quality. The ability to process different metals, including steel, aluminum, and titanium, without the need for tool changes makes metal laser cutting machines an invaluable asset in manufacturing and fabrication environments.

Furthermore, metal laser cutting machines contribute significantly to reducing production times and costs. Their high-speed operation and automation capabilities enable mass production runs with consistent quality, reducing the need for manual intervention and rework. This technology also enhances flexibility in manufacturing processes, allowing for quick adjustments and prototyping. Additionally, the integration of computer numerical control (CNC) systems ensures precision and repeatability, essential for maintaining stringent industry standards. As industries continue to advance, the adoption of metal laser cutting machines is set to grow, driven by their ability to meet the demands for high-quality, efficient, and versatile metal processing solutions.

Metal laser cutting machines play a pivotal role in the manufacturing of medical devices, offering unparalleled precision and efficiency. These machines utilize high-powered lasers to cut through metals with exceptional accuracy, making them ideal for creating intricate components required in medical instruments. For instance, surgical tools, stents, and orthopedic implants often demand precise geometries and smooth finishes to ensure safety and efficacy. Laser cutting meets these stringent requirements by providing clean, precise cuts without causing thermal damage to the surrounding material. This technology is particularly advantageous for working with metals like titanium and stainless steel, which are commonly used in medical devices due to their biocompatibility and strength.

Beyond cutting, metal laser cutting machines are also used for engraving and drilling in the medical field. They can create fine features and detailed patterns essential for diagnostic tools and devices, such as microfluidic chips and catheter tips. The versatility of laser cutting allows for rapid prototyping and customization of medical devices, catering to the evolving demands of personalized medicine. Furthermore, the non-contact nature of laser cutting minimizes the risk of contamination, a critical consideration in medical device manufacturing. Overall, metal laser cutting machines enhance the capability to produce high-quality, precise, and reliable medical devices that meet the rigorous standards of the healthcare industry.

Metal laser cutting machines have revolutionized the machining and manufacturing industries by offering unparalleled precision and efficiency. These machines utilize high-powered lasers to cut through various types of metals, including steel, aluminum, and titanium. The primary advantage of laser cutting lies in its ability to produce intricate designs and tight tolerances that are often unachievable with traditional cutting methods. This precision is achieved through the laser’s fine focus and the controlled movement of the cutting head, which is guided by computer numerical control (CNC) systems. Consequently, metal laser cutting machines are ideal for producing complex components in industries such as aerospace, automotive, and electronics, where accuracy and consistency are paramount.

In addition to precision, metal laser cutting machines significantly enhance manufacturing efficiency. The speed at which these machines operate, coupled with their ability to perform continuous, high-volume production runs, drastically reduces lead times. This efficiency is further bolstered by the minimal need for secondary processes, as laser cutting often results in clean edges and smooth finishes. Moreover, laser cutting is a versatile process that can be adapted for different material thicknesses and compositions without extensive retooling. This adaptability, along with reduced material waste due to the precision of the cuts, makes laser cutting a cost-effective solution in modern manufacturing. As a result, metal laser cutting machines have become a cornerstone in the drive towards lean manufacturing and high-quality production standards.

Sure, here are some FAQs for manufacturing “metal laser cutting machines quality work from SourcifyChina factory”:

Q: What materials can SourcifyChina’s metal laser cutting machines process?

A: SourcifyChina’s metal laser cutting machines can process a variety of metals including stainless steel, carbon steel, aluminum, copper, and brass. Our machines are designed to handle different thicknesses and grades to meet diverse industrial needs.

Q: How does SourcifyChina ensure the quality of its metal laser cutting machines?

A: Quality assurance is achieved through rigorous testing and inspection protocols at every production stage. We use high-quality components and adhere to international standards. Additionally, each machine undergoes a comprehensive performance test before shipment.

Q: What are the key features of SourcifyChina’s metal laser cutting machines?

A: Our machines feature high precision, fast cutting speeds, energy efficiency, and user-friendly interfaces. They also include advanced control systems, automated height adjustment, and robust build quality to ensure reliable and consistent performance.

Q: What support services does SourcifyChina offer for its laser cutting machines?

A: We provide comprehensive support including installation, training, maintenance, and technical assistance. Our dedicated customer service team is available to address any issues and ensure smooth operation of your machines.

Q: How does the pricing of SourcifyChina’s laser cutting machines compare with other manufacturers?

A: SourcifyChina offers competitive pricing without compromising on quality. We leverage our efficient manufacturing processes and economies of scale to provide cost-effective solutions for our customers.

Q: What is the delivery time for SourcifyChina’s metal laser cutting machines?

A: Delivery times vary depending on the order size and customization requirements. Typically, standard machines are delivered within 4-6 weeks. For customized orders, the delivery timeline will be provided upon consultation.

Q: Can SourcifyChina customize metal laser cutting machines according to specific needs?

A: Yes, we offer customization services to tailor our machines to your specific requirements. Our engineering team works closely with clients to design and produce machines that meet their unique needs.

These FAQs provide a snapshot of what you can expect from SourcifyChina in terms of quality, support, and customization options for metal laser cutting machines.

1. Understand the Market Needs:

– Assess the specific requirements of your target market, including the types of metals most commonly cut and the desired precision.

2. Choose the Right Technology:

– Fiber lasers are generally preferred for metal cutting due to their efficiency and precision. Ensure the machines you manufacture are equipped with high-quality fiber laser sources.

3. Focus on Machine Design:

– Optimize the design for durability and ease of maintenance. Use robust materials to withstand the rigors of metal cutting.

4. Precision and Speed:

– Invest in high-precision components and control systems to ensure accurate cuts. Balance cutting speed with quality to meet diverse customer needs.

5. Safety Features:

– Incorporate comprehensive safety features, such as protective enclosures, emergency stop buttons, and laser beam shields to protect operators.

6. Software Integration:

– Equip your machines with advanced CNC software that offers user-friendly interfaces, customizability, and support for various file formats.

7. Quality Control:

– Implement rigorous quality control procedures to ensure consistency and reliability in every machine. Regularly test and calibrate your machines to maintain high standards.

8. Customer Support and Training:

– Provide comprehensive training for operators and robust customer support. Offer resources such as manuals, tutorials, and online support to help users maximize the machine’s potential.

9. After-Sales Service:

– Establish a reliable after-sales service network. Offer maintenance, repair services, and readily available spare parts to keep your customers’ operations running smoothly.

10. Cost Efficiency:

– While maintaining high quality, strive for cost efficiency in production to offer competitive pricing. Explore sourcing high-quality yet affordable components.

11. Sustainability:

– Consider environmental factors by adopting energy-efficient technologies and reducing waste in the manufacturing process.

12. Compliance with Standards:

– Ensure your machines comply with international safety and quality standards, such as ISO and CE certifications, to facilitate global sales.

By focusing on these aspects, you can enhance the quality, reliability, and competitiveness of metal laser cutting machines produced at SourcifyChina factory.

Sure, here are the FAQs for sourcing metal laser cutting machines from SourcifyChina factory:

1. What types of metal laser cutting machines does SourcifyChina offer?

SourcifyChina offers a variety of metal laser cutting machines, including fiber laser cutting machines, CO2 laser cutting machines, and hybrid models. These machines cater to different cutting needs, from thin sheets to thicker metal plates.

2. What materials can SourcifyChina’s laser cutting machines handle?

SourcifyChina’s machines are designed to cut a wide range of materials, including stainless steel, carbon steel, aluminum, brass, copper, and other metal alloys.

3. What are the key features of SourcifyChina’s laser cutting machines?

Key features include high precision cutting, fast cutting speeds, energy efficiency, user-friendly interfaces, and robust build quality. Advanced models also offer automated loading and unloading systems, as well as smart control systems.

4. What is the delivery time for an order from SourcifyChina?

The typical delivery time ranges from 30 to 60 days, depending on the machine specifications and order volume. Customizations may affect delivery times.

5. Does SourcifyChina provide installation and training services?

Yes, SourcifyChina offers comprehensive installation and training services to ensure customers can efficiently operate their new laser cutting machines.

6. What kind of warranty and after-sales support does SourcifyChina provide?

SourcifyChina provides a standard warranty period of 1 to 2 years, covering parts and labor. They also offer extended warranties and lifetime technical support.

7. How can I request a quote or place an order?

You can request a quote or place an order by visiting SourcifyChina’s website, contacting their sales team via email or phone, or using their online inquiry form.

8. Are there any customization options available?

Yes, SourcifyChina offers customization options to meet specific cutting requirements, including machine size, power, and additional features.

9. How does SourcifyChina ensure the quality of their laser cutting machines?

SourcifyChina employs rigorous quality control measures, including pre-shipment inspections, performance testing, and compliance with international standards.

10. Can SourcifyChina assist with shipping and logistics?

Yes, SourcifyChina provides assistance with shipping and logistics, ensuring safe and timely delivery of your laser cutting machines.

Sourcing metal laser cutting machines from SourcifyChina factory involves a few key steps to ensure you get the best product for your needs:

– Material Type and Thickness: Specify the types of metals (e.g., steel, aluminum) and their thicknesses.

– Cutting Speed and Precision: Determine the required cutting speed and accuracy.

– Power and Size: Consider the machine’s power (watts) and size to fit your production capacity and workspace.

– Company Background: Check SourcifyChina’s history, production capabilities, and reputation.

– Certifications: Ensure they have necessary certifications like ISO9001, CE, or other relevant industry standards.

– References and Reviews: Look for customer reviews or ask for references to verify their credibility.

– Technical Specs: Compare technical details such as laser type (fiber, CO2), power output, and software compatibility.

– Sample Testing: Request samples of the machine’s cutting performance on your specified materials.

– Detailed Inquiry: Provide a clear and detailed inquiry to SourcifyChina, mentioning your specific requirements and expectations.

– Follow-up Questions: Ask about machine warranty, after-sales service, and technical support.

– Pricing: Discuss pricing, ensuring it includes all costs (shipping, taxes, customs).

– Payment Terms: Negotiate favorable payment terms, such as a deposit and balance upon delivery.

– Lead Time: Confirm the production and delivery lead times.

– Pre-Shipment Inspection: Arrange for a third-party inspection to verify the machine meets your specifications before shipping.

– Documentation: Ensure all shipping documents, manuals, and warranties are in order.

– Training: Ask about training for your staff on how to use the machine.

– Technical Support: Ensure there is reliable technical support for maintenance and troubleshooting.

By following these tips, you can effectively source a high-quality metal laser cutting machine from SourcifyChina, ensuring it meets your production needs and quality standards.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.