Technology and Applications of metal laser engraving machines

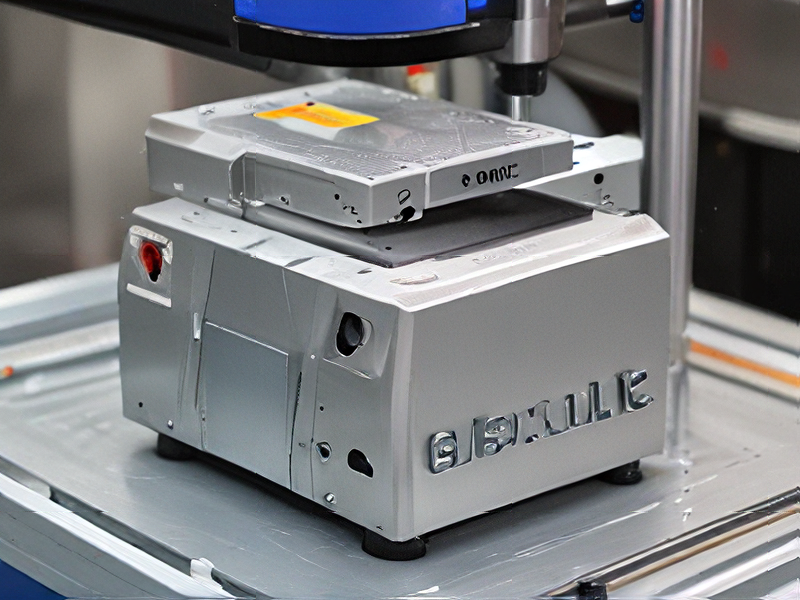

Metal laser engraving machines use laser technology to etch or mark metal surfaces with high precision. These machines employ fiber lasers, CO2 lasers, or diode lasers to create detailed patterns, texts, or images on metal. The laser beam’s high energy density allows it to vaporize or oxidize the metal surface, creating permanent marks.

Technology

1. Fiber Lasers: These are the most common in metal engraving due to their high efficiency and ability to engrave hard metals like stainless steel, aluminum, and titanium. They offer precise control, high speed, and deep engraving capabilities.

2. CO2 Lasers: Typically used for non-metal materials, but with the right setup, they can also engrave coated metals and anodized aluminum.

3. Diode Lasers: Less powerful than fiber lasers, suitable for lighter engraving tasks and marking softer metals.

Applications

1. Industrial Manufacturing: Laser engraving is used for creating serial numbers, barcodes, and logos on parts and products, ensuring traceability and brand identity. It’s crucial in sectors like automotive, aerospace, and electronics.

2. Jewelry and Personalization: Offers intricate designs and customization on jewelry pieces, watches, and personalized gifts, enhancing aesthetic appeal and uniqueness.

3. Medical Devices: Engraving on medical instruments and implants for identification, compliance with regulations, and ensuring patient safety.

4. Tool Marking: Marking tools and machinery parts with identification codes, operational instructions, or measurement scales.

5. Art and Decoration: Creating detailed artworks, decorative items, and trophies with high precision and durability.

Advantages

– Precision and Quality: Laser engraving delivers high-resolution marks without physical contact, reducing wear and tear.

– Speed and Efficiency: Fast engraving process with minimal setup time.

– Durability: Permanent marks that resist wear, corrosion, and high temperatures.

– Versatility: Suitable for various metals and applications, adaptable to different industry needs.

Metal laser engraving machines are essential in modern manufacturing and customization, offering unmatched precision, speed, and versatility.

Quality Testing Methods for metal laser engraving machines and how to control quality

Quality testing for metal laser engraving machines involves various methods to ensure precision, consistency, and durability of the engravings. Here’s a summary of the key methods and control measures:

Quality Testing Methods

1. Visual Inspection: Checking for defects such as rough edges, inconsistent depths, and unclean cuts.

2. Dimensional Accuracy: Using calipers and micrometers to measure the engraved dimensions against specifications.

3. Surface Roughness: Employing surface profilometers to assess the smoothness of engraved surfaces.

4. Laser Power and Focus Testing: Verifying the laser power output and focus using specialized meters and calibration tools.

5. Material Compatibility Tests: Engraving different metals to check the machine’s adaptability and consistency.

6. Durability Tests: Subjecting engraved samples to wear and environmental tests to assess the longevity of the engravings.

Quality Control Measures

1. Calibration: Regular calibration of the laser system to maintain accuracy and performance.

2. Environmental Control: Maintaining a controlled environment (temperature, humidity) to avoid affecting the laser’s performance.

3. Routine Maintenance: Scheduled cleaning and maintenance of laser optics, nozzles, and other critical components.

4. Operator Training: Ensuring operators are well-trained in using and maintaining the machines to reduce errors.

5. Software Updates: Keeping the control software up-to-date for improved functionality and accuracy.

6. Standardized Procedures: Implementing standardized operating procedures (SOPs) for consistency in the engraving process.

These methods and measures help maintain high-quality standards in metal laser engraving, ensuring reliable and precise outputs.

Tips for Procurement and Considerations when Purchasing from metal laser engraving machines

When procuring a metal laser engraving machine, several key factors and considerations can ensure you make an informed and beneficial purchase:

1. Understand Your Needs:

– Determine the specific types of metals you’ll be engraving and the complexity of the designs.

– Identify the production volume to decide between a machine suited for small-scale or industrial-scale operations.

2. Laser Type:

– Choose between fiber lasers, CO2 lasers, or Nd:YAG lasers. Fiber lasers are typically preferred for metal due to their efficiency and precision.

3. Power and Speed:

– Higher wattage lasers can cut and engrave faster and handle thicker materials but come at a higher cost. Balance power with your specific needs.

4. Precision and Quality:

– Evaluate the machine’s resolution (DPI) and accuracy. High-resolution machines produce finer details, crucial for intricate designs.

5. Software Compatibility:

– Ensure the machine’s software is user-friendly and compatible with common design programs like AutoCAD or CorelDRAW. Software features like design preview, layer management, and parameter settings are beneficial.

6. Maintenance and Support:

– Check for the availability of customer support, training, and maintenance services. Machines with easily replaceable parts and comprehensive support plans minimize downtime.

7. Safety Features:

– Look for safety features such as enclosed laser systems, proper ventilation, and safety interlocks to protect operators.

8. Budget:

– Consider not just the initial purchase price but also the total cost of ownership, including maintenance, consumables, and potential upgrades.

9. Supplier Reputation:

– Purchase from reputable suppliers with positive reviews and reliable after-sales service. Verify their experience in the industry and the warranty terms offered.

10. Compliance and Certification:

– Ensure the machine complies with relevant industry standards and certifications for quality and safety, such as CE marking.

By carefully evaluating these factors, you can select a metal laser engraving machine that meets your operational needs, budget constraints, and quality expectations, ensuring a successful investment.

FAQs on Sourcing and Manufacturing from metal laser engraving machines in China

When sourcing metal laser engraving machines from China, it’s essential to address several key FAQs:

1. Quality Assurance: Ensure the supplier provides detailed specifications and quality assurances, possibly through certifications like ISO standards.

2. Supplier Verification: Verify the supplier’s reputation through customer reviews, industry certifications, and onsite visits if feasible.

3. Customization Options: Check if the supplier offers customization options such as laser power, engraving area sizes, and additional features to meet specific needs.

4. Lead Times and Logistics: Inquire about lead times, shipping methods, and logistics arrangements to anticipate delivery schedules and potential delays.

5. Support and Warranty: Understand the warranty terms and after-sales support offered by the supplier to address potential maintenance or repair needs.

6. Cost Considerations: Compare pricing structures, including upfront costs, shipping fees, and potential import duties or taxes to calculate the total landed cost.

7. Intellectual Property Protection: Discuss measures the supplier takes to protect intellectual property rights, ensuring your designs and technologies remain secure.

8. Communication Channels: Establish clear communication channels and language proficiency to avoid misunderstandings during negotiations and ongoing support.

By addressing these FAQs, you can navigate the sourcing and manufacturing process of metal laser engraving machines from China more effectively, ensuring a smooth procurement experience aligned with your business requirements.