Technology and Applications of metal pipe cutter

A metal pipe cutter is a tool designed for cutting pipes made of various metals like steel, copper, and aluminum. The technology and applications of metal pipe cutters are diverse, spanning different industries and requirements.

Technology:

1. Manual Pipe Cutters: These are simple, handheld tools with a sharp cutting wheel. The user rotates the cutter around the pipe, tightening it until the pipe is cut through. They are ideal for small-scale jobs and thin-walled pipes.

2. Electric and Battery-Operated Pipe Cutters: These tools offer more power and precision. They are equipped with a motor that drives the cutting mechanism, making them suitable for cutting thicker and tougher pipes quickly and efficiently.

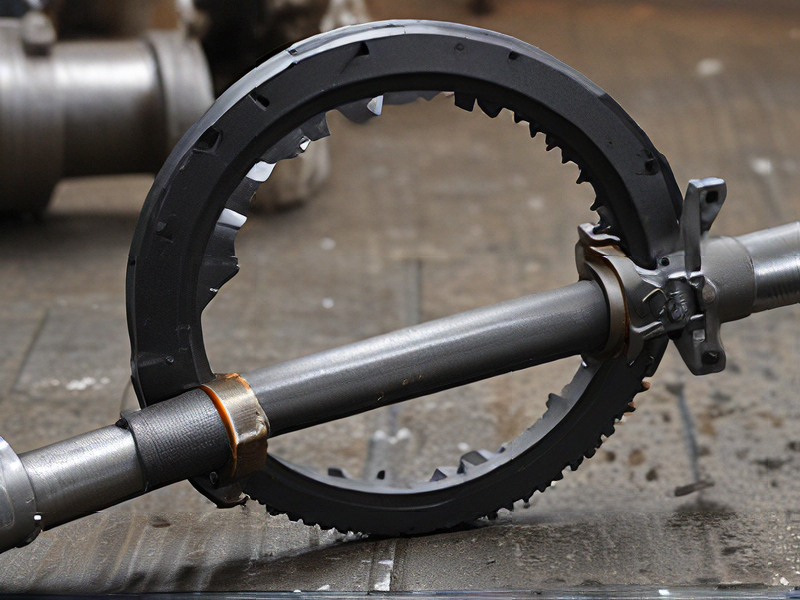

3. Rotary Pipe Cutters: These are used for large-diameter pipes. The cutter is clamped around the pipe and rotates to make the cut. It is often used in industrial applications.

4. Chain Pipe Cutters: These cutters use a chain equipped with cutting wheels. The chain wraps around the pipe, and the user tightens it to make the cut. They are useful for cutting pipes in tight or awkward spaces.

5. Plasma and Laser Cutters: These high-tech options use plasma or laser beams to cut through metal pipes with high precision. They are used in advanced manufacturing and specialized industries.

Applications:

1. Plumbing: Pipe cutters are essential for installing and repairing plumbing systems. They provide clean and precise cuts, which are crucial for fitting pipes correctly.

2. HVAC: In heating, ventilation, and air conditioning systems, pipe cutters are used to size pipes for ductwork and coolant lines.

3. Construction: Metal pipe cutters are used to cut structural pipes and conduits in construction projects.

4. Automotive and Aerospace: Precision pipe cutters are used in these industries to cut pipes for fuel lines, hydraulics, and other critical systems.

5. Manufacturing: In various manufacturing processes, pipe cutters help in creating components and assemblies that require precise pipe sections.

Metal pipe cutters are indispensable tools in many industries, offering precision, efficiency, and versatility. Their technology ranges from simple manual tools to advanced laser cutters, catering to a wide array of cutting needs.

Quality Testing Methods for metal pipe cutter and how to control quality

To ensure the quality of a metal pipe cutter, several testing methods can be employed throughout its production process:

1. Dimensional Inspection: Measure critical dimensions such as blade diameter, cutting capacity, and overall tool length to ensure they meet specifications.

2. Material Analysis: Conduct tests like spectroscopy or hardness testing to verify the quality and composition of the cutter’s materials, ensuring they meet strength and durability requirements.

3. Performance Testing: Subject the cutter to operational tests to evaluate its cutting precision, speed, and efficiency under simulated working conditions.

4. Durability Testing: Perform endurance tests to assess the cutter’s lifespan and resistance to wear and tear, ensuring it meets expected longevity standards.

5. Safety Testing: Validate safety features such as blade guards and ergonomic design through usability tests to prevent accidents and ensure user comfort.

To control quality effectively:

– Establish Standards: Define clear quality standards and specifications for every component and stage of production.

– Supplier Management: Select reliable suppliers for raw materials and components, ensuring they meet quality standards and provide consistent materials.

– Process Control: Implement quality control checkpoints throughout manufacturing, including inspections after each production stage to catch defects early.

– Training and Certification: Train staff on quality standards and procedures, encouraging continuous improvement and adherence to best practices.

– Feedback Mechanism: Establish a feedback loop from customers and field tests to identify potential issues and areas for improvement.

By integrating these testing methods and quality control measures, manufacturers can produce metal pipe cutters that meet high standards of performance, durability, and safety.

Tips for Procurement and Considerations when Purchasing from metal pipe cutter

When purchasing a metal pipe cutter, several key considerations can ensure you make an informed procurement decision:

1. Type of Cutter: Choose between manual, electric, or hydraulic cutters based on your needs. Manual cutters are portable and suitable for occasional use, while electric or hydraulic cutters are more powerful and efficient for frequent or heavy-duty tasks.

2. Pipe Diameter and Material: Ensure the cutter is compatible with the diameter and material of pipes you commonly work with (e.g., steel, copper, PVC). Different materials may require specific blade types or cutter designs.

3. Cutting Capacity and Thickness: Verify the cutter’s capacity to handle the thickness of pipes you typically work with. Consider both outer diameter (OD) and wall thickness specifications.

4. Accuracy and Precision: Look for features that ensure clean, square cuts without burrs or deformation, especially important for pipes used in plumbing or industrial applications.

5. Durability and Build Quality: Opt for cutters made from robust materials (e.g., hardened steel blades, durable frames) to withstand repeated use and tough working conditions.

6. Ease of Use and Maintenance: Choose a cutter that is ergonomic, easy to operate, and requires minimal maintenance. Features like quick-adjust mechanisms can enhance usability.

7. Safety Features: Prioritize cutters with safety features such as blade guards, emergency stop buttons, or ergonomic grips to reduce the risk of accidents during operation.

8. Brand Reputation and Reviews: Research reputable brands and read user reviews to gauge reliability, performance, and customer support.

9. Cost and Value: Consider the initial cost versus long-term value, factoring in efficiency, durability, and maintenance requirements over the cutter’s lifespan.

10. Warranty and Support: Check for warranty coverage and available customer support to address potential issues or concerns post-purchase.

By carefully evaluating these factors, you can select a metal pipe cutter that best suits your operational needs, ensuring efficiency, safety, and long-term reliability in your procurement decision.

FAQs on Sourcing and Manufacturing from metal pipe cutter in China

FAQs on Sourcing and Manufacturing Metal Pipe Cutters in China

1. Why source metal pipe cutters from China?

China is a leading global manufacturer due to its cost-effective production, advanced manufacturing technology, and a wide range of suppliers, providing both quality and affordability.

2. How to find reliable manufacturers?

Use platforms like Alibaba, Made-in-China, and Global Sources. Verify suppliers through reviews, certifications, and by requesting product samples. Visiting trade shows and factory tours can also help.

3. What certifications should I look for?

Look for ISO certifications (like ISO 9001 for quality management), CE marking for compliance with European standards, and any specific certifications relevant to your industry or region.

4. What is the typical MOQ (Minimum Order Quantity)?

MOQs vary by manufacturer but typically range from 500 to 1,000 units. Some suppliers may offer lower MOQs for higher prices or during initial orders to build a relationship.

5. How do I ensure product quality?

Request samples, conduct factory audits, and implement third-party quality inspections. Establish clear specifications and quality standards in your contract.

6. What are the payment terms?

Common payment terms include T/T (Telegraphic Transfer), with 30% deposit upfront and 70% before shipment, and L/C (Letter of Credit). Some suppliers might accept PayPal or other methods for smaller amounts.

7. What is the lead time for manufacturing?

Lead times typically range from 30 to 60 days, depending on order size and production schedules. Factor in additional time for shipping and customs clearance.

8. How to handle shipping and logistics?

Manufacturers can assist with shipping arrangements. Choose between FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms. Collaborate with freight forwarders for smooth logistics management.

9. What if there are issues with the products?

Address potential issues in your contract, including quality control procedures, warranty terms, and dispute resolution mechanisms. Open communication with suppliers is key to resolving problems efficiently.

By following these guidelines, you can effectively source and manufacture metal pipe cutters from China, ensuring quality and cost-efficiency in your supply chain.