“SourcifyChina: Reliable Factory for Precision Milling Machines – Expert Definitions and Insights”

In this informative piece, we delve into SourcifyChina’s reliable factory specializing in precision milling machines. Gain expert insights and definitions to understand why this manufacturer stands out in quality and innovation.

Choosing SourcifyChina Factory for purchasing a milling machine ensures quality and reliability. They rigorously test every unit for top-notch performance, making them a trusted name in the industry.

SourcifyChina provides comprehensive customer support, guiding buyers from selection to post-purchase services. Their dedicated team ensures a smooth procurement process, minimizing potential issues.

Moreover, SourcifyChina offers competitive pricing without compromising on quality. Their extensive network and efficient supply chain management allow them to provide cost-effective solutions.

Lastly, buyers benefit from SourcifyChina’s commitment to innovation. They continuously improve their products, incorporating the latest technology to meet evolving market demands, ensuring customers get the best value.

A milling machine is a tool used to shape solid materials by removing excess parts. It operates by rotating a cutting tool, often a rotary cutter, against a workpiece to achieve the desired design and dimensions.

Types and Options for Milling Machines:

– Horizontal Milling Machine: This machine relies on a horizontally oriented spindle. Known for handling heavier and larger materials better than its vertical counterpart.

– Vertical Milling Machine: Utilizing a vertically aligned spindle, this machine excels in precision and is commonly used for small to medium-sized projects.

– Knee-Type Milling Machine: Features a vertically adjustable worktable that rests on a saddle, which sits on a “knee” bracket. Very versatile, often used in workshops and labs.

– Bed-Type Milling Machine: Features a worktable that isn’t adjustable vertically. The consistent bed height offers stability and is suitable for heavy-duty tasks.

– Planer-Type Milling Machine: Equipped with a planning mechanism, these machines are ideal for large and heavy workpieces. They offer accurate straight cuts over longer stretches.

– CNC Milling Machine: Controlled by a computer, this type allows for precise and repeatable operations. Ideal for complex and high-volume operations.

– Universal Milling Machine: Combines the features of horizontal and vertical machines, offering flexibility for various tasks.

– Turret Milling Machine: Equipped with a spindle fixed to a turret that can move in different directions, allowing for a variety of complex operations.

Each type offers distinct advantages, making the selection dependent on specific project requirements, materials, and accuracy needs.

A milling machine is a versatile tool used in metalworking and woodworking to shape materials. It rotates a cutting tool to remove material from a workpiece, achieving precise dimensions and shapes.

Applications of Milling Machine:

– Manufacturing complex parts for automotive and aerospace industries.

– Creating custom molds and dies for plastic or metal components.

– Fabricating and finishing metal or wooden frames.

– Producing gears, slots, and other precision components.

– Drilling, boring, and tapping holes in a variety of materials.

– Prototyping new designs quickly with high accuracy.

– Engraving detailed designs or text on surfaces.

– Reconditioning worn parts through precise machining.

– Creating intricate patterns and textures on materials.

– Assembling complex projects by machining individual parts.

– Surface finishing for a polished appearance.

– Adjusting and fitting custom mechanical parts.

– Production of small batches of precision parts for aerospace.

– Machining heavy-duty parts for industrial machinery.

– Creating components for medical devices and equipment.

– Making customized parts for robotics and automation.

– Shaping metals for military and defense applications.

– Crafting bespoke jewelry and decorative items.

– Machining parts for electronic devices and enclosures.

– Tool and die making for mass production.

– Machining complex features such as Heatsinks for electronics industry.

– Milling sculpted parts and prototypes for the fashion industry.

– Machining plastic parts for consumer goods.

– Producing components for renewable energy devices like wind turbines.

– Educational purposes in machining and engineering courses.

– Customized parts production for the marine industry.

– Cutting precision slots for mechanical assemblies.

– Crafting wooden furniture with intricate designs.

– Electrical discharge machining (EDM) preparation.

– Precision cutting for clock and watch parts.

– Creating parts for rail transport equipment.

– Machining specialty components for food processing machinery.

SourcifyChina Milling Machine Definition

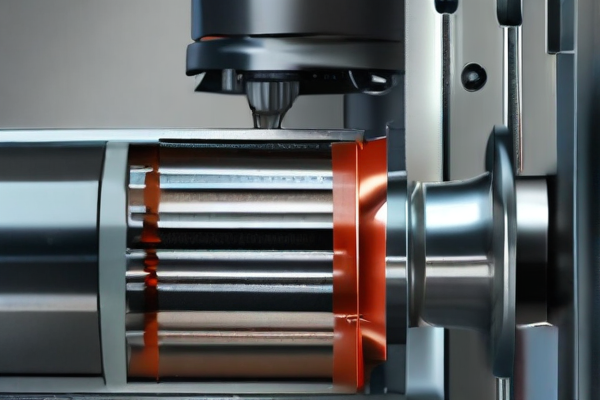

SourcifyChina’s milling machines are precision tools used for shaping and cutting metal, wood, and other solid materials. They employ rotary cutters to remove material, offering high accuracy and efficiency.

The materials used in constructing SourcifyChina milling machines include high-grade cast iron and steel. These materials ensure durability, stability, and resistance to wear and tear. Superior materials also enhance the machine’s ability to perform intricate machining tasks without compromising on quality.

The use of advanced alloys and composite materials further improves the machine’s performance. Enhanced rigidity and thermal stability are crucial for maintaining dimensional accuracy during prolonged machining processes.

In addition to traditional metals and composites, SourcifyChina incorporates cutting-edge technology, such as high precision ball screws and linear guides. These components are crucial for achieving exceptional accuracy and extended machine life, ensuring consistent performance even in demanding industrial settings.

Moreover, SourcifyChina’s milling machines are designed with ergonomic and user-friendly interfaces, making them accessible for operators of varying skill levels. The combination of robust materials and innovative design ensures that SourcifyChina’s milling machines meet the high standards of modern manufacturing industries.

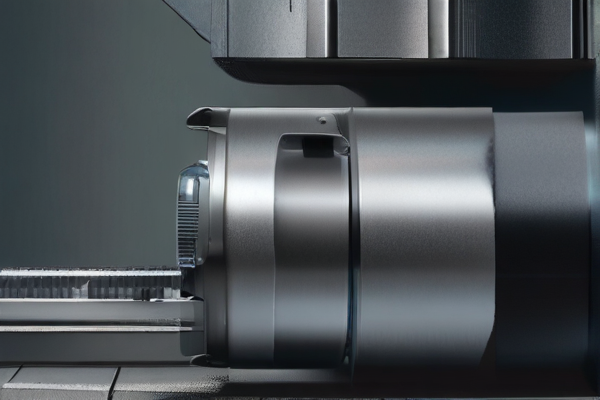

SourcifyChina specializes in the production of top-quality milling machines, recognized for their precision and durability. A milling machine cuts and shapes materials like metal and wood, essential for various industrial applications.Today we’ll focus on the quality control manufacturing process.

At SourcifyChina, quality control begins with raw material selection. Only top-grade metals and components are chosen, ensuring the final product’s longevity and reliability. Each batch is rigorously tested for compliance with industry standards.

Throughout the manufacturing process, CNC (Computer Numerical Control) systems are utilized for precision. These systems ensure that every component is machined to exact specifications, minimizing errors and maximizing efficiency. Automated inspections are performed regularly to maintain consistency.

Post-production, each milling machine undergoes extensive testing. This includes operational tests to ensure performance standards are met, as well as safety checks to avoid any potential hazards. Engineers monitor machine precision, speed, and overall functionality.

The final step involves customer documentation and feedback integration. Manuals are provided to end-users to guarantee proper operation and maintenance. Customer feedback is analyzed to make continuous improvements, ensuring SourcifyChina’s milling machines remain at the forefront of the industry.

By adhering to stringent quality control measures, SourcifyChina guarantees the production of world-class milling machines. The dedication to quality and precision not only meets but often exceeds customer expectations, establishing a strong reputation in the global market.

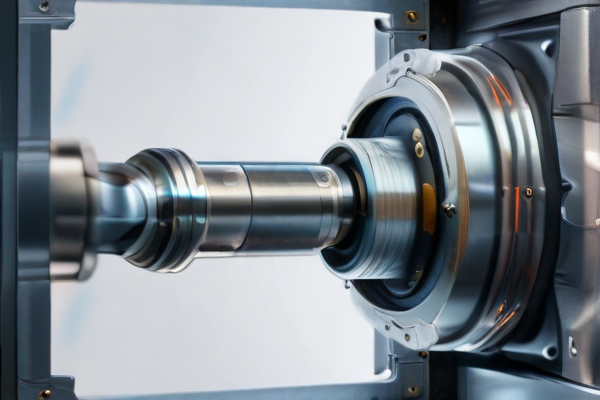

SourcifyChina is a leading supplier of milling machines, known for their precision and reliability in the manufacturing sector. These machines are designed to mill various materials with high accuracy, making them suitable for both small-scale and large-scale productions. Their robust design incorporates advanced technology that ensures seamless operations and minimal downtime, enhancing productivity.

The capabilities of SourcifyChina milling machines are vast, offering multi-axis operations and a wide range of spindle speeds. This versatility makes them ideal for tasks requiring intricate detailing and large-scale material removal. They excel in producing components with tight tolerances, which is crucial in industries like aerospace, automotive, and electronics.

Additionally, these milling machines support Computer Numerical Control (CNC), allowing for the automation of complex machining processes. This feature reduces human error and ensures consistent output, significantly improving manufacturing efficiency. Users can program the machine to perform repetitive tasks with high precision, making it an invaluable asset for mass production.

User-friendly interfaces and enhanced safety features are other noteworthy aspects. Operators can easily monitor and adjust operational parameters through intuitive controls, ensuring optimal performance. Safety mechanisms prevent accidents, safeguarding both the machine and its operators. Regular software updates and customer support services further enhance the user experience, making SourcifyChina milling machines a reliable choice for various machining needs.

In summary, SourcifyChina milling machines combine precision, versatility, and user-friendly features to deliver exceptional performance in various industrial applications. Their advanced capabilities, including multi-axis operations, CNC support, and robust safety mechanisms, make them a desirable investment for manufacturers seeking to improve productivity and maintain high-quality output.

A milling machine is a versatile tool primarily used for shaping solid materials such as metal, wood, and plastic through the removal of material by rotary cutters.

Benefits of a Milling Machine:

– Versatility:

– Capable of performing various operations like cutting, drilling, and milling complex shapes.

– Facilitates a wide array of tasks including flat surfaces, slots, and gears.

– Precision:

– High accuracy in shaping and detailing materials.

– Ideal for the production of complex components requiring tight tolerances.

– Efficiency:

– Fast material removal rates improve project timelines.

– Reduced manual labor, which increases productivity.

– Customization:

– Adaptable to both small and large-scale operations.

– Suitable for custom projects and prototyping.

– Consistency:

– Delivers consistent and repeatable results.

– Ensures quality and uniformity in mass production.

– Reduced Waste:

– Offers precise material cutting, which minimizes wastage.

– Cost-effective in material usage.

– Automation:

– CNC milling machines improve automation and reduce the need for manual intervention.

– Enhanced capability for intricate design and complex shapes through programmed commands.

– Durability:

– Constructed with robust materials to handle high-stress operations.

– Long-lasting machinery requiring minimal maintenance.

– Flexibility:

– Ability to work with different materials including metals, plastics, and wood.

– Adjustable settings for different cutting speeds and depths.

– Training and Skill Development:

– Offers hands-on experience for machinists and engineers.

– Develops essential skills in manufacturing and material processing.

Overall, milling machines are indispensable in modern manufacturing due to their versatility, precision, and efficiency, making them valuable assets in various industrial applications.

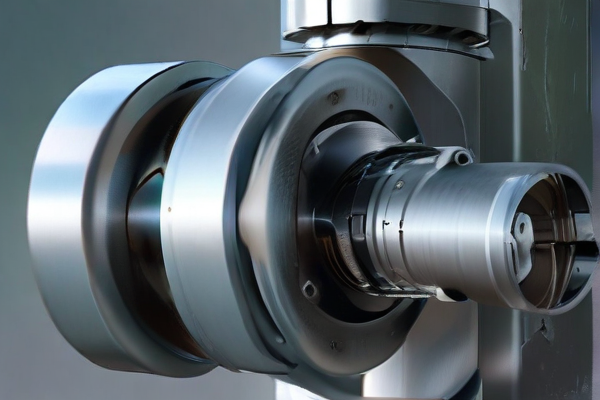

A milling machine is a versatile tool essential for industrial manufacturing, enabling precise material removal from a workpiece. It utilizes rotary cutters to shape, drill, and finish materials.

Key Features of a Milling Machine:

– Variable Speed Control: Adjustable spindle speeds allow for diverse machining operations on various materials.

– Precision: Provides accurate cuts with fine tolerances, critical in high-precision industries.

– Versatility: Supports a range of cutting tools and operations like drilling, facing, and contouring.

– Automated and Manual Options: Available in both CNC (Computer Numerical Control) and manual configurations.

– Movable Work Table: Facilitates multi-directional movement of the workpiece for intricate machining tasks.

– Tool Changer: CNC machines often include automatic tool changers to improve efficiency and reduce downtime.

– Coolant Systems: Integrated coolant systems help manage heat and prolong tool life.

– Heavy-Duty Construction: Ensures stability and durability under rigorous machining conditions.

– Digital Readouts (DRO): Enhance accuracy by providing precise measurements of table and spindle positions.

– Safety Features: Includes guards, emergency stops, and interlocks to ensure operator safety.

By combining these features, milling machines offer unparalleled capabilities in crafting precise components across a myriad of industries.

SourcifyChina excels in providing custom products and projects with their advanced milling machines. These machines are essential in shaping metal and other solid materials to create precise components. The definition of a milling machine is a power-driven machine used for rotating cutting tools to remove material from a workpiece, achieving intricate designs and accurate dimensions.

Their expertise lies in crafting tailored solutions to meet unique client specifications. Whether it’s a small-batch prototype or mass production, SourcifyChina offers high-quality, custom-fabricated items using state-of-the-art technology. The milling machines operate with precision, ensuring each product meets stringent standards and client requirements.

In addition to custom product manufacturing, SourcifyChina also handles diverse projects that require milling capabilities. This ranges from intricate engineering designs to large-scale industrial applications. Their team of skilled professionals collaborates closely with clients to ensure project success, utilizing their vast experience and the latest in milling technology.

SourcifyChina’s commitment to excellence is evident in every custom product they deliver. With a focus on innovation and quality, they provide reliable, efficient solutions that cater to the specific needs of their clients. Trust SourcifyChina to bring your complex designs to life with their precision milling machines and expert craftsmanship.

SourcifyChina is a notable company specializing in the sourcing and supply of precision milling machines, catering predominantly to industrial and manufacturing sectors. Established with a commitment to bridging the gap between quality Chinese manufacturing capabilities and global market demands, SourcifyChina has positioned itself as a crucial intermediary in the machinery industry. Specifically, the company offers a range of milling machines, designed to accommodate various machining operations such as cutting, drilling, and shaping metal and other solid materials with exceptional accuracy and efficiency. SourcifyChina’s expansive portfolio includes both standard and customized milling solutions, ensuring that clients find machines that align perfectly with their technical specifications and production goals. With a focus on innovation, reliability, and cost-effectiveness, the company leverages extensive industry expertise and a robust network of manufacturers to provide state-of-the-art machinery. Moreover, SourcifyChina prides itself on comprehensive customer service, offering installation support, training, and maintenance to guarantee optimal performance and longevity of the machines it supplies.

A milling machine, defined as a versatile machine tool used for precision cutting, shaping, and drilling of materials, finds significant applications in the aerospace, defense, and marine industries. In aerospace, milling machines are employed to manufacture complex components such as turbine blades, aircraft structural parts, and intricate airframe assemblies. The high precision and accuracy offered by computer numerical control (CNC) milling machines ensure that these components meet stringent tolerances required for flight safety and performance. Materials such as titanium, aluminum, and specialized alloys, commonly used in aerospace, are adeptly handled by these machines, enabling the production of lightweight yet robust parts essential for aircraft efficiency and reliability.

In the defense sector, milling machines are crucial for manufacturing critical components for military hardware, ranging from weapon systems to armored vehicle parts. Precision milling allows for the creation of intricate geometries and complex surface profiles, which are essential for the effectiveness and durability of defense equipment. Additionally, milling machines contribute to the development and maintenance of naval vessels in the marine industry. Ship components such as propellers, engine parts, and structural elements require high precision and durability to withstand harsh oceanic conditions. Milling machines, particularly those equipped with advanced CNC technology, ensure that these components are produced within exacting specifications, enhancing the overall performance and longevity of maritime assets. Thus, the milling machine’s capability for precise material manipulation underscores its indispensable role in these high-stakes industries.

Milling machines are vital in the automotive industry, utilized extensively for the production of various vehicle components. These machines perform precise metal cutting and shaping operations, allowing the creation of parts with intricate geometries and exact dimensions. Engine components such as cylinder heads, blocks, and intake manifolds are commonly produced using milling machines, ensuring optimal performance and durability. The high-speed machining capabilities of modern milling machines also facilitate the production of lightweight components, which are crucial for enhancing vehicle fuel efficiency. Furthermore, the flexibility of milling operations supports the development of prototype components and the adaptation of designs to meet ever-evolving automotive standards.

In the realm of electronics, milling machines play an essential role in the fabrication of printed circuit boards (PCBs) and other intricate electronic components. These machines can efficiently remove material from substrates like copper-clad laminates to create the necessary pathways and contact points required for electrical circuits. Milling machines also contribute to the manufacture of enclosures and casings for electronic devices, ensuring precision in size and fit to protect sensitive electronic components from environmental factors. Additionally, these machines are integral in the rapid prototyping process for electronic devices, allowing designers to quickly iterate and refine their designs. This synergy between precision, speed, and flexibility makes milling machines indispensable in the ever-advancing field of electronics manufacturing.

A milling machine, typically defined as a versatile piece of machinery used to shape and cut materials, has pivotal applications in the construction industry. In construction, precision and efficiency are critical, and milling machines are indispensable assets. These machines are utilized to produce components like gears, fasteners, and structural parts with exact specifications, which are fundamental in the erection of buildings, bridges, and other infrastructures. Advanced CNC (Computer Numerical Control) milling machines have further streamlined the manufacturing process, enabling mass production of custom parts with minimal human intervention. This not only enhances productivity but also significantly reduces the margin of error, ensuring a higher standard of quality in construction projects.

In the energy sector, milling machines play a crucial role in the fabrication and maintenance of equipment essential for energy production and distribution. For instance, in the renewable energy domain, components for wind turbines, solar panels, and hydroelectric systems often require intricate designs and precise dimensions, which are efficiently handled by milling machines. Additionally, in traditional energy industries such as oil and gas, these machines are used to create parts for drilling rigs, pipelines, and refineries. The accuracy and flexibility of milling machines support the efficient operation and longevity of critical energy infrastructure, thereby contributing to a stable and reliable energy supply. The integration of these machines in both renewable and conventional energy sectors underscores their importance in fostering innovation and ensuring the efficient harnessing of energy resources.

The industrial equipment industry heavily relies on milling machines, a vital component in the manufacturing and processing sector. A milling machine is defined as a tool designed to remove material from a workpiece through the rotational motion of cutting tools. These machines can perform precision cutting, shaping, and drilling operations on metal, wood, and other solid materials, making them indispensable in various industrial applications. The versatility of milling machines allows for the creation of complex parts and components integral to industries such as aerospace, automotive, and engineering. By automating and refining manufacturing processes, milling machines contribute significantly to increased efficiency, accuracy, and production speed, ultimately boosting productivity and reducing operational costs.

In practical terms, the application of milling machines in the industrial equipment sector is vast and multifaceted. These machines are employed to produce gears, engine components, molds, and intricate parts that require high precision and consistency. Advanced computer numerical control (CNC) milling machines have revolutionized the industry by allowing for programmable operations that enhance repeatability and reduce human error. This is particularly beneficial in high-volume production scenarios where consistency and speed are paramount. Additionally, the ability to perform multi-axis machining enables the creation of complex geometries and designs that would be challenging or impossible with traditional machining methods. Consequently, milling machines not only streamline the production process but also expand the possibilities of innovation and design within the industrial equipment industry.

A milling machine is a sophisticated piece of machinery used to perform complex operations such as cutting, shaping, and drilling materials, typically metal or plastic. In the medical device industry, milling machines are essential for manufacturing high-precision components required for medical instruments and implants. These machines utilize rotary cutters to remove material from a workpiece, meticulously crafting surgical tools, prosthetic devices, and intricate parts for diagnostic equipment. The ability to create detailed and precise cuts with tight tolerances is crucial in producing devices that must meet stringent regulatory standards and perform reliably within the human body.

The precision and versatility of milling machines enable the production of customized components tailored to individual patient needs, such as custom orthopedic implants that match the unique anatomy of a patient. Advanced milling techniques, including CNC (Computer Numerical Control) milling, allow manufacturers to achieve exceptional accuracy and repeatability, reducing the risk of human error and ensuring consistency across batches. This capability is particularly important in the medical field, where even the slightest deviation can have significant implications for patient safety and treatment efficacy. In summary, milling machines play a vital role in the medical device sector by delivering the high-quality, custom components necessary for modern medical care.

A milling machine is a versatile and fundamental piece of equipment in the machining and manufacturing industry. It is designed to remove material from a workpiece via rotary cutters that move at various speeds and angles. The milling process allows for the precise shaping of materials, such as metals, plastics, and composites, by following a predetermined pattern dictated by the machine’s programmable features. With capabilities to produce complex geometries, milling machines are vital in creating components such as gears, slots, and intricate 3-dimensional shapes. Among their various types, the most common include vertical and horizontal milling machines, each suited for different specific applications but both integral to high-precision manufacturing tasks.

In the realm of manufacturing, milling machines are indispensable for their high efficiency and adaptability. They are frequently employed in numerous industries such as aerospace, automotive, electronics, and medical device manufacturing. In aerospace, for example, milling machines are employed to produce precisely engineered and highly stress-resistant components like turbine blades and structural parts. Automotive manufacturers use them for making engine parts, transmissions, and various custom components. The flexibility of milling machines also supports rapid prototyping processes, allowing manufacturers to move swiftly from design to functional prototypes, thus accelerating the overall production cycle. Their fine tolerances, combined with continuous improvements in CNC (Computer Numerical Control) technology, make milling machines critical for modern manufacturing, enabling the production of sophisticated and accurate products on a large scale.

Certainly! Here are some FAQs regarding the manufacturing of milling machines and quality work from SourcifyChina factory:

Q1: What is a milling machine?

A1: A milling machine is a mechanical device used for machining solid materials. It employs rotary cutters to remove material, creating a variety of shapes and designs. Milling machines are essential in many manufacturing processes, offering precision and efficiency.

Q2: How does SourcifyChina ensure the quality of its milling machines?

A2: SourcifyChina ensures quality through rigorous quality control processes. This includes using high-grade materials, conducting extensive testing, and adhering to international manufacturing standards. Continuous improvement initiatives and customer feedback also play key roles.

Q3: What types of milling machines does SourcifyChina manufacture?

A3: SourcifyChina manufactures a range of milling machines including vertical, horizontal, and CNC (Computer Numerical Control) models. Each type is designed to meet specific industry needs, from small-scale production to large industrial applications.

Q4: Can I customize a milling machine according to my requirements?

A4: Yes, SourcifyChina offers customization options to meet specific client needs. You can discuss your requirements with their engineering team to design a machine tailored to your production specifications.

Q5: What are the lead times for manufacturing and delivery?

A5: Lead times can vary based on the complexity and customization of the order. Generally, standard milling machines can be delivered within 4-6 weeks, while custom orders may take longer. It is best to consult directly with SourcifyChina for precise timelines.

Q6: What after-sales services does SourcifyChina provide?

A6: SourcifyChina offers comprehensive after-sales services including installation support, operator training, maintenance, and technical assistance. The goal is to ensure seamless operation and maximum uptime for their clients’ milling machines.

Q7: How does SourcifyChina handle quality concerns or defects?

A7: SourcifyChina has a dedicated customer service team to handle any quality concerns. They offer warranties and after-sales support to address defects promptly. Clients can expect replacement parts or repairs to be swiftly arranged.

Please let me know if you need more detailed information or additional questions answered.

Sourcing a milling machine from a reputable manufacturer like SourcifyChina can significantly impact your production efficiency and product quality. Here are some tips to ensure you make an informed decision:

1. Vertical vs. Horizontal Mills: Vertical mills are versatile and suitable for precise cutting, drilling, and boring. Horizontal mills are robust for heavy-duty operations.

2. 3-Axis vs. Multi-Axis: 3-axis machines are great for straightforward tasks, while 4 or 5-axis machines handle complex geometrics and improve production time.

1. Certifications: Look for ISO 9001, CE, or other relevant certifications that indicate quality and compliance with international standards.

2. Experience: Check the manufacturer’s history and expertise in producing milling machines. Companies with a long track record usually offer more reliable products.

1. Spindle Speed and Power: Higher spindle speeds and powerful motors allow faster material removal and smoother finishes.

2. Table Size and Weight Capacity: Make sure the table size and weight capacity align with your production requirements.

1. Precision and Tolerances: Ask for documented evidence of the machine’s precision and tolerances. High precision is key to manufacturing high-quality parts.

2. Warranty and Support: Ensure the manufacturer offers comprehensive warranty and reliable customer support.

1. Shipping and Delivery: Understand the shipping options, costs, and delivery timelines. Timely delivery can be crucial for your business operations.

2. Customs and Duties: Be aware of any customs processes and additional costs involved in importing machinery.

1. Initial Cost vs. Long-Term Value: While it might be tempting to opt for cheaper machines, consider total lifecycle costs, including maintenance and potential downtime.

Following these guidelines will help you source a high-quality milling machine from SourcifyChina, catered to your specific manufacturing needs.

Q: What is the definition of a milling machine?

A: A milling machine is a versatile tool used in machining to remove material from a workpiece by rotating cutting tools. It can perform various operations like cutting, drilling, and surface finishing to create complex shapes and high-precision components.

Q: Does SourcifyChina factory provide high-quality milling machines?

A: Yes, SourcifyChina factory is known for manufacturing high-quality milling machines that meet international standards. They focus on precision, durability, and advanced technology in their machines.

Q: What types of milling machines are available at SourcifyChina factory?

A: SourcifyChina factory offers a variety of milling machines including vertical, horizontal, CNC (Computer Numerical Control), and manual milling machines to cater to different machining needs.

Q: How can I request a quote for a milling machine from SourcifyChina factory?

A: You can request a quote by visiting SourcifyChina’s official website and filling out the contact form, or by sending an inquiry email with your specifications and requirements.

Q: What information do I need to provide for a milling machine order?

A: Provide detailed specifications including the type of milling machine, size, desired features, production volume, and any customization requirements. This helps the factory deliver an accurate quote and timeline.

Q: Are customized milling machines available at SourcifyChina factory?

A: Yes, SourcifyChina factory offers customized solutions tailored to your specific requirements. Contact their customer service to discuss your customization needs.

Q: What is the typical delivery time for a milling machine from SourcifyChina factory?

A: Delivery times vary based on the complexity of the order and current production schedules. Typically, you can expect a lead time of 4 to 8 weeks after order confirmation.

Q: Does SourcifyChina factory offer after-sales service and support?

A: Yes, they provide comprehensive after-sales service including installation, training, maintenance, and technical support to ensure optimal performance of the milling machines.

Q: Can I visit SourcifyChina factory to inspect the milling machines before purchase?

A: Yes, you are welcome to visit SourcifyChina factory for a detailed inspection of their milling machines. Contact their sales team to schedule a visit.

Q: What payment methods does SourcifyChina factory accept?

Sourcing a milling machine definition from a reliable manufacturer like SourcifyChina can be streamlined with a few strategic steps. Here are some tips to help you through the process efficiently:

1. Research and Identify Credible Suppliers:

– Start by visiting SourcifyChina’s website and evaluate their range of milling machines.

– Look for manufacturers with positive reviews, certifications, and years of experience in the industry.

2. Understand Your Requirements:

– Clearly define what kind of milling machine you need – whether it’s a vertical or horizontal milling machine, CNC or manual.

– Specify other requirements like machine size, capacity, precision level, and additional features.

3. Direct Communication:

– Reach out to SourcifyChina directly through their contact forms or customer service.

– Prepare a concise and clear message outlining your requirements and any questions you may have.

4. Ask for Detailed Specifications:

– Request detailed specifications and technical data for the milling machines.

– This should include information on materials, dimensions, power consumption, and operational capabilities.

5. Request a Definition or Product Description:

– Ask the supplier to provide a standard definition or description of the milling machine as per their catalog.

– Ensure this definition includes the machine’s functions, typical applications, and advantages.

6. Validate Authenticity:

– Verify certifications and compliance with international standards.

– Check if they can provide references or case studies of previous customers.

7. Consider After-Sales Support:

– Inquire about warranties, maintenance services, and availability of spare parts.

– Ensure the manufacturer offers sufficient after-sales support and technical assistance.

By following these steps, you can acquire a detailed milling machine definition and ensure you’re dealing with a reputable supplier like SourcifyChina. Effective communication and thorough research are key to a successful sourcing experience.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.