Reliable Source for SourcifyChina Factory Horizontal Milling Machines: Quality and Efficiency Guaranteed

In today’s global market, finding a trustworthy supplier for high-quality machinery is crucial. SourcifyChina’s factory delivers top-notch horizontal milling machines that ensure precision, durability, and optimal performance for various industrial applications. Discover unmatched reliability with our specialized equipment.

SourcifyChina Factory offers extensive experience in manufacturing high-quality milling machines, ensuring reliability and efficiency. Their expertise guarantees that each machine meets international standards, making them a trusted partner for global buyers.

Competitive pricing sets SourcifyChina apart. By leveraging local resources and cost-effective production methods, they offer superior milling machines at a fraction of the cost compared to other suppliers, providing excellent value.

Comprehensive support is a hallmark of SourcifyChina Factory. From initial inquiry to after-sales service, their dedicated team assists buyers, ensuring a smooth procurement process and immediate resolution of any issues that may arise.

Customization is a key advantage with SourcifyChina. Buyers can tailor milling machines to their specific requirements, allowing for greater flexibility and ensuring that the final product perfectly fits their unique industrial needs.

Quality control is stringent at SourcifyChina Factory. Thorough inspections and rigorous testing protocols are in place throughout the manufacturing process, ensuring that each milling machine is reliable, durable, and performs optimally in various conditions.

SourcifyChina also emphasizes timely delivery. Their streamlined production and logistics processes ensure that orders are fulfilled promptly, minimizing downtime and helping buyers maintain consistent operational schedules.

Sustainability is a priority for SourcifyChina. The factory employs eco-friendly production methods and adheres to environmental regulations, offering buyers a way to reduce their carbon footprint without compromising on product quality.

In conclusion, choosing SourcifyChina Factory for purchasing horizontal milling machines means opting for experience, affordability, customized solutions, robust quality control, prompt delivery, and a commitment to sustainability. These benefits make SourcifyChina Factory the ideal choice for discerning buyers worldwide.

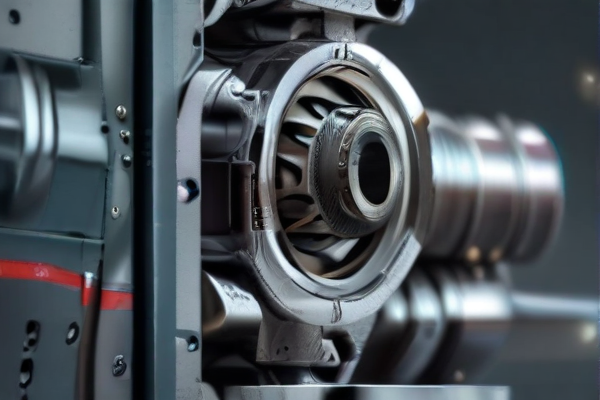

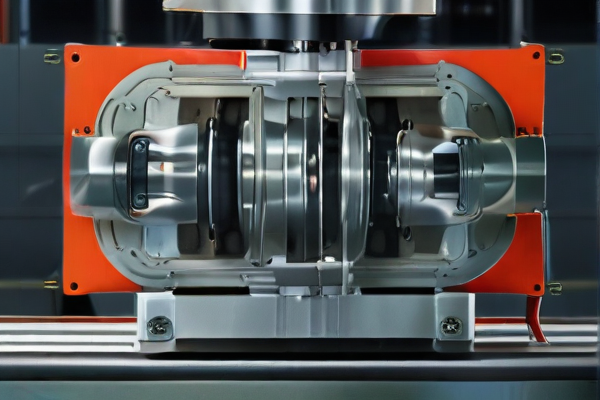

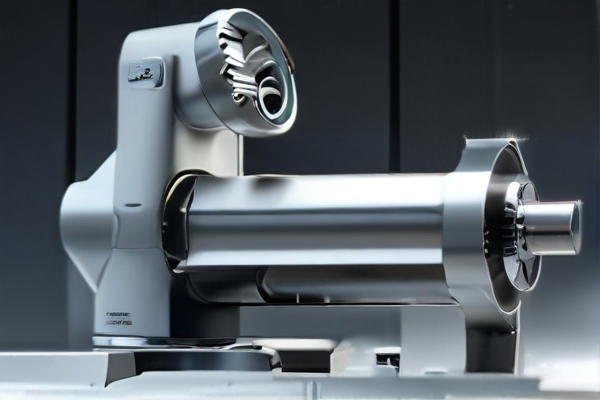

A horizontal milling machine features a horizontally oriented spindle, performing multi-axis machining operations with precision. It’s suitable for a range of materials and large-scale production. The most common types include plain, universal, and omniversal milling machines.

– Plain Horizontal Milling Machine: Basic model, primarily for simple tasks.

– Universal Horizontal Milling Machine: Capable of complex operations, with a swiveling table.

– Omniversal Horizontal Milling Machine: Combines features of both plain and universal types.

– Horizontal Boring Mills: Specialized for boring large holes.

– Bed-Type Milling Machines: Known for rigid construction, suited for large, heavy workpieces.

– Knee-Type Milling Machines: Offers mobility and flexibility for varied tasks.

– Hobbing Machines: Used primarily for gear cutting.

– Planer-Type Milling Machines: Suitable for heavy-duty work with larger dimensions.

– Double Column Milling Machines: Provide more support for industrial-scale projects.

– Special-Purpose Milling Machines: Customized for unique applications in specialized industries.

Options and features:

– Automatic Tool Changers (ATC): Enhance productivity by reducing manual intervention.

– CNC Controls: Support high precision and complex machining tasks.

– Rotary Tables: Allow for additional rotational movement and workpiece positioning.

– Coolant Systems: Improve tool life and machining accuracy by maintaining optimal temperatures.

– Automation and Robotics: Increase efficiency, especially in high-volume production.

– Spindle Speed Variability: Facilitates machining of different materials and finishes.

– Advanced Cutting Tools: Tailored to specific materials and machining requirements, from high-speed steel to carbide-tipped tools.

– Power Feeds: Reduce operator fatigue and improve consistency in long operations.

Choosing the right horizontal milling machine depends on production needs, material types, and precision requirements, making careful consideration of these types and options crucial for optimal machining performance.

Horizontal milling machines are versatile tools used in various industries for material removal and shaping. They excel in cutting complex shapes and making precise cuts, contributing to the manufacturing process.

– Automotive Industry: Fabrication of engine blocks, transmission cases, and other components.

– Aerospace Industry: Manufacturing of intricate aircraft parts such as brackets, ribs, and engine mounts.

– Tool and Die Making: Creation of molds, dies, and intricate machining tools.

– Metalworking: Precision cutting, grooving, and slotting in metal parts.

– Construction Equipment Manufacturing: Production of heavy-duty components used in construction machinery.

– Furniture Making: Crafting detailed wooden pieces and frames.

– Medical Device Manufacturing: Production of precision parts for medical instruments and implants.

– Prototyping: Preparation of prototypes and one-off designs in various materials.

– Shipbuilding: Creation of large, precise components for maritime vessels.

– Electronics: Precision manufacturing of circuit boards and electronic components.

– Gear Manufacturing: Cutting gears, splines, and other transmission components.

– Energy Sector: Milling precise components for turbines, generators, and other energy-producing equipment.

– Railway Industry: Production of railway track components and train parts.

– General Manufacturing: Multi-purpose applications across small to large-scale production lines.

Horizontal milling machines offer precision and efficiency, making them indispensable in diverse industrial applications.

The “SourcifyChina milling machine horizontal” is made from high-grade cast iron, ensuring excellent durability and stability during heavy operations. This choice of material minimizes vibrations, leading to more accurate milling.

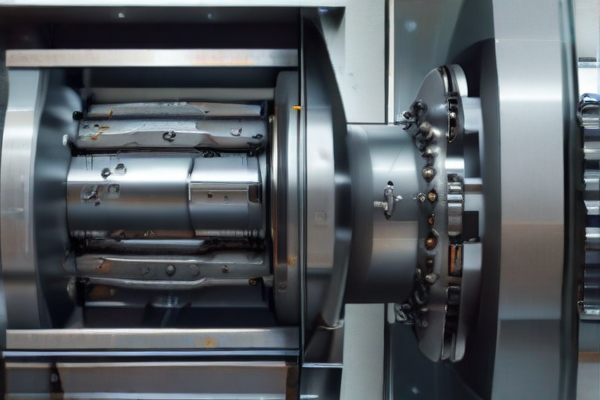

The machine’s components, such as the spindle and gear wheels, are crafted from hardened steel. This material offers outstanding wear resistance and longevity, essential for maintaining precision over extended periods of use.

Its table and vise are usually composed of stainless steel or alloy steel, offering good corrosion resistance and high tensile strength. This ensures that the machine can handle heavy loads without deforming.

Lastly, various protective covers and casings are made from durable polymers or aluminum, safeguarding the internal mechanisms from dust, debris, and other potential contaminants. This combination of materials contributes to the product’s overall reliability and efficient performance, making it a robust choice for various milling operations.

SourcifyChina’s horizontal milling machines undergo a rigorous quality control process to ensure superior functionality and durability. Each component is meticulously inspected before assembly, adhering to international standards.

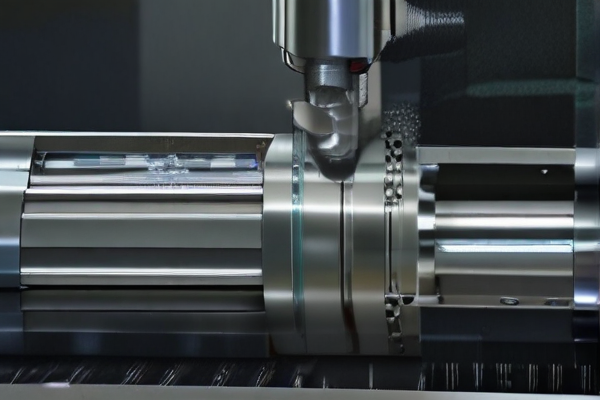

Advanced technologies like CNC programming and precision lasers are employed in the manufacturing stage. These tools enhance the accuracy and reliability of the milling machines, minimizing deviations and defects.

During assembly, skilled technicians conduct performance tests to verify each machine’s operational efficiency. Stress tests simulate real-world conditions, ensuring the equipment can withstand demanding environments over extended periods.

The final quality control stage involves comprehensive inspections and calibrations. Only machines that meet stringent criteria are dispatched to customers. This unwavering commitment to quality guarantees dependable, high-performance horizontal milling machines from SourcifyChina.

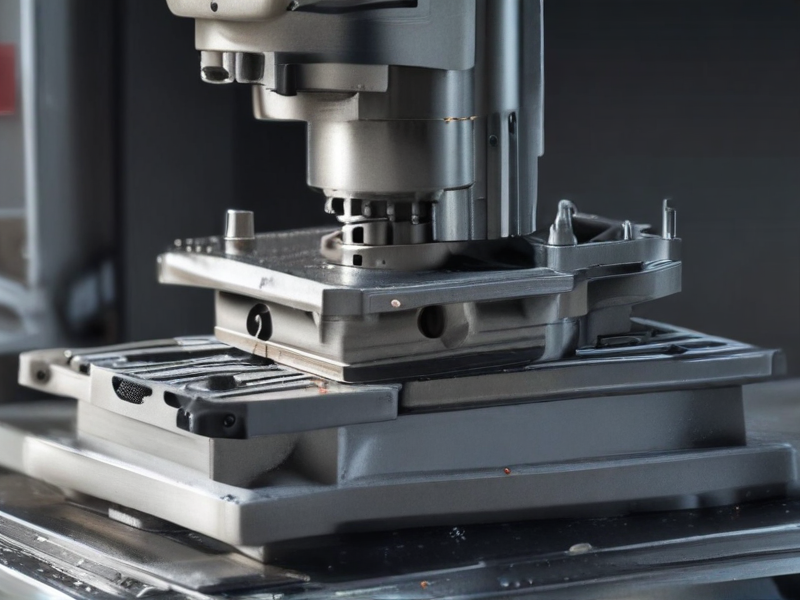

SourcifyChina milling machine horizontal capabilities include robust versatility, capable of handling a wide array of machining processes. It can perform milling, drilling, boring, and cutting tasks with high precision, ensuring consistent results in various manufacturing applications. The machine is built with durable materials, extending its operational lifespan and reliability.

Its advanced CNC control system allows for precise and efficient programming, enabling complex designs to be executed flawlessly. This automation also reduces human error, enhancing production efficiency and quality. Operators can easily adjust settings to accommodate different materials and machining requirements.

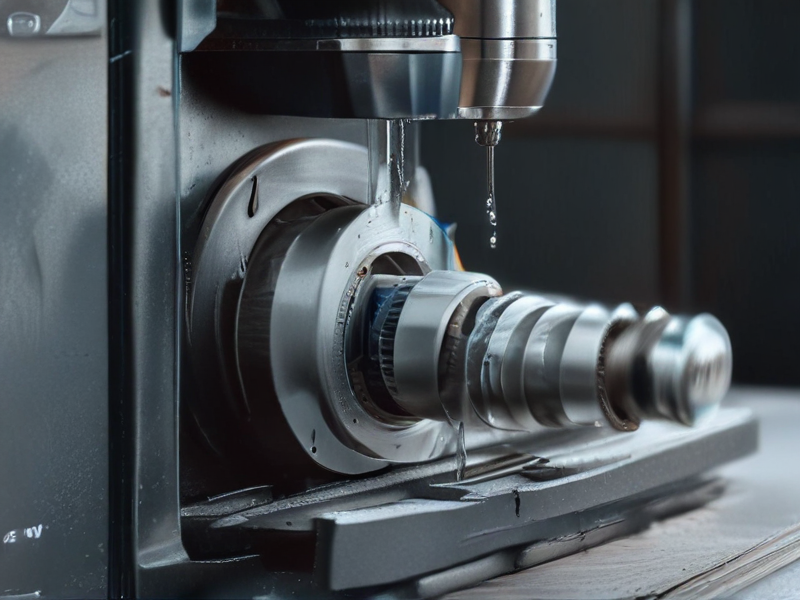

Equipped with a high-torque spindle, the machine can handle tough materials, including metals and composites, providing uniform cuts and finishes. Its horizontal design enables better chip evacuation, promoting a cleaner work environment and minimizing any potential damage to the workpiece.

Additionally, the SourcifyChina horizontal milling machine offers scalable integration into existing production lines, allowing manufacturers to expand their capabilities without extensive overhaul. This flexibility makes it an ideal choice for both small workshops and large-scale industrial operations aiming to maintain high productivity levels.

A horizontal milling machine offers a variety of benefits, making it a versatile and valuable tool in manufacturing and machining operations.

– Efficient Material Removal: Horizontal milling machines can remove material faster and more efficiently than their vertical counterparts, thanks to their robust design and the gravitational force aiding chip removal.

– Stability and Precision: The design of horizontal mills provides greater stability and precision, crucial for creating detailed and intricate components.

– Versatility: They can use a wide range of cutting tools and attachments, making them highly versatile and suited for various machining tasks.

– Complex Shaping Capability: Horizontal milling machines can perform complex and multi-sided machining operations with ease, enhancing productivity.

– Reduced Machining Time: Their ability to work on multiple sides of the workpiece in one setup significantly reduces machining time.

– Heavy-Duty Applications: Designed for high-performance, horizontal mills are ideal for heavy-duty and large-scale production runs.

– Improved Surface Finish: The precise control and stability of horizontal mills contribute to a superior surface finish on the machined parts.

– Enhanced Tool Lifespan: The efficient chip removal and reduced heat generation during operation help in extending the lifespan of cutting tools.

– Ideal for Slotting and Grooving: Particularly effective for slotting and grooving applications due to the horizontal spindle orientation.

– Customized Configurations: Can be customized with various accessories and attachments to meet specific machining needs.

In summary, horizontal milling machines offer numerous advantages, including efficient material removal, enhanced stability, and versatility, which make them indispensable in various industrial applications.

Horizontal milling machines are highly efficient for heavy-duty operations due to their robust construction and horizontal spindle orientation. These machines are ideal for machining large and heavy workpieces.

Features:

– Spindle Orientation: The spindle is positioned horizontally, allowing for deeper and larger cutting.

– Worktable: Extensive worktable for holding multiple fixtures and larger working areas.

– Cutting Tools: Utilizes cylindrical cutters that provide greater cutting surface area.

– Multiple-Axis Functionality: Capable of multi-axis machining for complex shapes and angles.

– Overarm Support: Offers additional rigidity and support to the spindle, enhancing precision.

– High Torque: Delivers superior torque, making it suitable for heavy material removal.

– Automation: Often equipped with CNC controls for enhanced automation and precision.

– Durability: Built for long-term use with high-durability components.

– Coolant Systems: Integrated coolant systems to manage heat during intensive operations.

– Versatility: Adaptable for various milling operations, such as face milling, slotting, and more.

SourcifyChina specializes in custom horizontal milling machines, providing tailored solutions to meet industry-specific needs. With precision engineering, they ensure high quality and efficiency.

Their horizontal milling machines are designed for optimal performance, integrating advanced technology to handle complex tasks. Each unit is crafted with attention to detail, ensuring durability and reliability.

SourcifyChina collaborates with clients to develop customized milling solutions. They focus on understanding project requirements, offering expert guidance from concept through production for specialized applications.

Commitment to excellence drives their innovation. They stay updated with industry trends to offer cutting-edge milling machinery, enhancing productivity and precision in various manufacturing sectors.

SourcifyChina’s custom products and projects are defined by their responsiveness to client needs. A tailored approach ensures that each milling machine aligns perfectly with specific operational demands, fostering client satisfaction.

SourcifyChina Milling Machine Horizontal stands as a beacon of innovation and quality in the realm of industrial machinery. Established in the bustling heart of China’s manufacturing district, this company has rapidly earned a reputation for producing state-of-the-art horizontal milling machines that are both robust and highly efficient. SourcifyChina prides itself on a customer-centric approach, diligently incorporating feedback into product development and prioritizing after-sales service. Known for their durability and precision, the horizontal milling machines from SourcifyChina cater to diverse industries, from automotive to aerospace, ensuring unrivaled precision in every cut. Their advanced technology and stringent quality control measures make them a preferred choice globally, especially for businesses aiming to optimize production and maintain consistency. Additionally, SourcifyChina is not just committed to excellence in machining solutions but also to sustainable practices, continually innovating to reduce the environmental impact of their operations and products. Their commitment to excellence, coupled with competitive pricing, positions SourcifyChina as a formidable player in the global milling machine market.

Milling machines, particularly horizontal variants, play a crucial role in the aerospace, defense, and marine industries due to their versatility and precision. In the aerospace sector, the demand for high-tolerance components made from advanced materials like titanium and aluminum is paramount. Horizontal milling machines are integral in the production of airframe components, engine parts, and intricate assemblies, ensuring that each piece meets stringent aerodynamic and structural standards. The ability of horizontal milling machines to cut multiple sides of a workpiece simultaneously enhances efficiency and precision, creating complex geometries and reducing the need for additional machining steps. This results in faster production times and lower overall costs, which is critical in an industry where time-to-market and performance reliability are always at the forefront.

In the defense and marine sectors, horizontal milling machines are equally invaluable. For defense applications, these machines are instrumental in manufacturing critical components for land, naval, and air systems, ensuring that military hardware is robust and reliable. Components such as missile casings, radar parts, and armor plating require the high-precision machining capabilities provided by horizontal milling machines. Similarly, in the marine industry, these machines are used to fabricate parts for shipbuilding, including propellers, engine components, and structural elements. The harsh operating environments necessitate parts that can withstand corrosion, stress, and dynamic loads, demanding the precision machining and material compatibility offered by horizontal milling machines. In all these fields, the adoption of computer numerical control (CNC) technology in horizontal milling machines further enhances their capability, allowing for automated, repeatable, and highly accurate production processes that meet the critical specifications required in aerospace, defense, and marine applications.

Horizontal milling machines play a pivotal role in the automotive industry, providing the precision and versatility necessary to manufacture complex components. These machines are adept at creating intricate parts such as engine blocks, transmission cases, and other large automotive components that demand high accuracy and consistency. By utilizing horizontal milling, automotive manufacturers can achieve superior surface finishes and tight tolerances, which are crucial for ensuring the optimal performance and longevity of vehicle parts. Additionally, the ability of horizontal milling machines to handle heavy-duty cutting and their capacity for multiple cutting tools make them indispensable in streamlining production processes and reducing lead times. The advancements in CNC technology further empower these machines, enabling the integration of automation, reducing human error, and enhancing overall productivity in automotive manufacturing.

In the electronics industry, horizontal milling machines are instrumental in the fabrication of various parts and components critical to the functioning of electronic devices. These machines are used to mill circuit boards, heat sinks, and enclosures with high precision, catering to the constantly shrinking scales of today’s electronic products. The horizontal milling process ensures that components maintain their structural integrity and meet stringent national and international quality standards. Their ability to accurately create complex geometries is particularly advantageous for developing custom electronic components that require exact specifications. Furthermore, horizontal milling machines can handle a wide array of materials, including metals, plastics, and composites, making them highly versatile in producing parts for diverse electronic applications, from consumer gadgets to sophisticated telecom infrastructure. Through continuous advancements, horizontal milling machines contribute significantly to innovation, efficiency, and miniaturization in the electronics sector.

A horizontal milling machine is a versatile tool in the construction industry, integral for shaping and cutting materials with precision. One significant application is in the creation of complex components for infrastructure projects such as bridges, tunnels, and buildings. The horizontal spindle design enables the machine to handle heavy, large, and intricate workpieces with ease. This functionality is crucial in construction, where custom metal and wooden constructs are often required. The machine’s ability to mill surfaces at different angles improves structural integrity and ensures that all components fit seamlessly, ultimately enhancing the durability and longevity of construction projects.

In the energy sector, horizontal milling machines are instrumental in manufacturing components for wind turbines, solar panels, and other energy-generating equipment. The precision milling capabilities are vital for creating gears, crankshafts, and rotors that are essential for the efficient operation of these devices. For wind turbines, the milling machine’s precision in cutting and shaping large, heavy blades and components directly impacts energy output and operational efficiency. Similarly, in solar technology, the machine aids in creating high-quality frames and mounts that accommodate photovoltaic cells, ensuring optimal angle and secure positioning for maximum sunlight absorption. Thus, the horizontal milling machine not only streamlines manufacturing processes but also plays a pivotal role in advancing sustainable energy solutions.

The industrial equipment sector has seen significant advancements with the adoption of horizontal milling machines, which have become essential in precision engineering and large-scale manufacturing. Horizontal milling machines are adept at removing substantial amounts of material with high efficiency, making them ideal for heavy-duty tasks like cutting gears, grooving, and slotting. Unlike vertical mills, their horizontal spindle orientation allows for more stability and reduced vibration, crucial for producing accurate and consistent parts. This makes them highly suitable for industries such as aerospace, automotive, and heavy machinery, where precision and reliability are paramount. Furthermore, the ability to accommodate larger workpieces enhances their application in constructing complex components, ensuring both reliability and high throughput.

In the context of the automotive industry, horizontal milling machines are indispensable for manufacturing engine blocks, transmission cases, and other critical components that require meticulous attention to detail and robust construction. Their capability to handle hard materials like cast iron and steel with ease contributes to extending the lifecycle of tooling and reducing production downtime. These machines also support automation features, such as CNC programming, which streamlines the manufacturing process by allowing for repeatable and scalable production. As a result, horizontal milling machines play a vital role in achieving lower manufacturing costs and shorter lead times, thus enhancing the overall efficiency and competitiveness of the industrial equipment sector.

The application of horizontal milling machines in the production of medical devices is pivotal due to their ability to achieve high precision and repeatability, essential for the stringent requirements of the healthcare industry. These machines play a crucial role in the fabrication of custom implants, such as knee and hip replacements, where exact geometrical tolerances are critical. The horizontal milling configuration allows for enhanced material removal rates and improved surface finishes, which are vital for components that need to meet strict regulatory standards. Additionally, the versatility of horizontal mills enables the machining of complex shapes and contours often required in dental implants and surgical instruments, ensuring that the final products meet both functional and biocompatibility requirements.

Moreover, horizontal milling machines contribute significantly to cost efficiency and productivity in medical device manufacturing. Their ability to handle multiple operations in a single setup reduces the need for frequent part repositioning, minimizing downtime and potential for errors. This efficiency is particularly important in the medical field, where production runs can vary from high-volume components to highly specialized, patient-specific devices. Automation and advanced computer numerical control (CNC) capabilities integrated into modern horizontal mills further enhance precision and consistency, allowing for the rapid scaling of production without compromising quality. In an industry where reliability and performance can directly impact patient outcomes, the role of horizontal milling machines in ensuring the delivery of safe and effective medical devices cannot be overstated.

Milling machines, particularly those with a horizontal configuration, are essential tools in machining and manufacturing industries due to their versatility and ability to create precision parts. Horizontal milling machines have a spindle that is aligned horizontally, allowing for the use of rotating cutting tools that remove material from a workpiece. This configuration is highly efficient for cutting operations that demand substantial material removal and robust machining processes. Industrial applications frequently employ horizontal milling machines for producing gears, slots, and complex three-dimensional shapes in metals and other hard materials. Moreover, their capability to handle heavy workpieces and maintain rigidity during machining supports high-volume production, making these machines integral to sectors such as automotive, aerospace, and heavy machinery.

In manufacturing, the application of horizontal milling machines extends beyond mere material removal, contributing significantly to various stages of product development and assembly. They are employed in the early stages of prototyping, enabling engineers to create detailed components with close tolerances that match design specifications precisely. During mass production, horizontal milling machines ensure consistent quality and dimensional accuracy, enhancing the overall efficiency of manufacturing operations. Additionally, they are often integrated into computer numerical control (CNC) systems, which automate the machining process and enable the production of complex parts with minimal human intervention. This automation reduces labor costs, minimizes errors, and increases production speeds, thereby reinforcing the role of horizontal milling machines as indispensable assets in modern manufacturing ecosystems.

Sure, here are some frequently asked questions (FAQ) along with their answers regarding the manufacturing of horizontal milling machines from SourcifyChina factory:

Q: What types of horizontal milling machines does SourcifyChina manufacture?

A: SourcifyChina offers a wide range of horizontal milling machines, including knee-type, planer-type, and bed-type machines, designed to meet varying industrial needs.

Q: How does SourcifyChina ensure the quality of their horizontal milling machines?

A: SourcifyChina follows stringent quality control processes, conducts rigorous testing, and adheres to international manufacturing standards to ensure superior quality and performance of their milling machines.

Q: Can SourcifyChina customize the milling machines as per specific requirements?

A: Yes, SourcifyChina offers customization options to tailor milling machines according to specific technical requirements and operational needs of their clients.

Q: What materials can be processed using SourcifyChina’s horizontal milling machines?

A: These machines are capable of processing a variety of materials, including metals such as steel, aluminum, brass, and other alloys, as well as non-metallic materials like plastic and wood.

Q: What after-sales services does SourcifyChina provide?

A: SourcifyChina provides comprehensive after-sales services, including installation assistance, operational training, regular maintenance, technical support, and availability of spare parts.

Q: How efficient are SourcifyChina’s horizontal milling machines?

A: SourcifyChina’s horizontal milling machines are designed for high efficiency, precision, and durability, ensuring optimal performance in various industrial applications.

Q: Are SourcifyChina’s milling machines compliant with international safety standards?

A: Yes, SourcifyChina ensures that all their milling machines comply with international safety standards, featuring essential safety mechanisms to protect operators and prevent accidents.

Q: What is the lead time for delivery of horizontal milling machines from SourcifyChina?

A: The lead time typically ranges from 4 to 8 weeks, depending on the complexity and customization requirements of the order. SourcifyChina strives to meet delivery deadlines to ensure timely supply.

Q: Do SourcifyChina’s horizontal milling machines come with a warranty?

A: Yes, all horizontal milling machines from SourcifyChina come with a standard one-year warranty that covers manufacturing defects and workmanship.

Q: How can I place an order for a horizontal milling machine from SourcifyChina?

When dealing with horizontal milling machines from SourcifyChina Factory, several key considerations can optimize your experience:

1. Understand Specifications: Familiarize yourself with the specific model, ensuring it meets your requirements in terms of spindle speed, table size, and power. SourcifyChina typically provides detailed brochures outlining these specs.

2. Quality Assurance: Ensure the machines undergo stringent quality checks. Inquire about ISO certifications and any other relevant quality standards. SourcifyChina is known for adhering to international benchmarks, but verification is essential.

3. Customization Options: Many factories, including SourcifyChina, offer customization. Discuss potential modifications to fit your unique manufacturing needs better.

4. After-Sales Support: Confirm the availability of after-sales service. SourcifyChina generally offers extensive support, including installation, training, and maintenance. Knowing the extent of this support can save time and reduce downtime.

5. Supply Chain Efficiency: Evaluate the factory’s supply chain and logistics efficiency. SourcifyChina has a robust logistics network, but ensuring timely delivery and inventory management is crucial for uninterrupted production.

6. Technical Training: Proper training is essential for optimal operation. SourcifyChina often provides comprehensive training for operators and maintenance staff. Take full advantage of this to maximize productivity.

7. Competitive Pricing: While SourcifyChina offers competitive pricing, it’s wise to compare with other suppliers to ensure you are getting the best deal. Bulk orders might also attract discounts.

8. Client Testimonials: Look for reviews and testimonials from other clients to gauge reliability and performance. Positive feedback from other users can be a good indicator of machine quality.

Leveraging these tips can lead to a successful acquisition and utilization of horizontal milling machines from SourcifyChina Factory, ultimately enhancing your manufacturing operations.

Q: What types of horizontal milling machines does SourcifyChina factory offer?

A: SourcifyChina factory offers a variety of horizontal milling machines, including standard, universal, and CNC-controlled models, catering to different industrial needs and specifications.

Q: Are the horizontal milling machines customizable?

A: Yes, SourcifyChina provides customizable options to meet specific requirements, including tailored configurations on size, speed, and additional features based on your project needs.

Q: What is the lead time for delivery after placing an order?

A: Typically, the lead time ranges from 4 to 8 weeks depending on the order volume and customization requirements. For precise lead times, it’s best to contact SourcifyChina directly.

Q: What kind of warranty and after-sales service is provided?

A: SourcifyChina offers a standard one-year warranty on all horizontal milling machines. They also provide comprehensive after-sales services, including remote technical support and on-site assistance if needed.

Q: How can I obtain a quote for a horizontal milling machine?

A: To get a quote, you can visit SourcifyChina’s website and fill out the inquiry form or contact their sales team directly via email or phone. Providing detailed project specifications will help in generating an accurate quote.

Q: What quality control measures are in place at SourcifyChina factory?

A: SourcifyChina employs strict quality control processes including material inspection, precision testing, and performance evaluations to ensure that every machine meets international standards.

Q: Can I visit the factory for an inspection before purchase?

A: Yes, SourcifyChina welcomes prospective clients to visit their factory for a tour and inspection. You can schedule a visit by contacting their customer service team.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods such as T/T (Telegraphic Transfer), L/C (Letter of Credit), and other mutually agreed upon terms to facilitate the transaction process.

Q: Do they provide training for operating the horizontal milling machines?

A: Yes, SourcifyChina offers training sessions for operators, either at their facility or at your site, to ensure proper and efficient use of the machinery.

Q: Are spare parts readily available?

A: SourcifyChina maintains a supply of essential spare parts and can quickly source additional parts if needed, ensuring minimal downtime for repairs and maintenance.

Sourcing a horizontal milling machine from SourcifyChina can be streamlined with the following tips:

1. Research and Identification: Clearly define the specifications and requirements for the horizontal milling machine. This includes dimensions, power, speed, and any additional features that are critical for your application.

2. Use Reliable Platforms: Visit legitimate sourcing platforms such as Alibaba, Globalsources, or Made-in-China. These platforms list verified suppliers including SourcifyChina and offer reviews and ratings.

3. Verify Supplier Credentials: Check SourcifyChina’s credentials including business licenses, certifications, and factory audits. A trustworthy supplier will often have ISO certification or other quality assurances.

4. Request Quotes and Compare: Contact SourcifyChina with detailed requests for quotes. Compare prices, machinery specifications, and terms with other potential suppliers to ensure you are getting a competitive deal.

5. Assess Communication: Ensure that the supplier’s communication is prompt and professional. Clear and effective communication helps in avoiding misunderstandings and ensures smooth transactions.

6. Sample and Inspection: If feasible, request a sample machine or visit the factory to inspect the machinery. Alternatively, you can hire third-party inspection services to ensure the machine meets quality standards before shipment.

7. Negotiate Terms: Negotiate favorable terms including payment terms, delivery schedules, and incoterms. Secure partial payments and retain a portion until after successful inspection upon arrival.

8. Legal Contracts: Draft clear contracts that outline every agreed detail. Include clauses for warranty, after-sales service, and dispute resolution to protect your interests.

Following these steps will help in finding a reliable horizontal milling machine supplier and ensure a successful purchase process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.