Technology and Applications of part machine

Part machines, or CNC (Computer Numerical Control) machines, are crucial in modern manufacturing, enabling precision, efficiency, and automation. These machines, including lathes, mills, and routers, follow programmed instructions to fabricate components with exact specifications. They revolutionize industries by producing complex parts that are difficult or impossible to make manually.

Technology Behind Part Machines

1. Computer Control: CNC machines are driven by CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, which convert designs into numerical codes. These codes direct the machine’s movements and operations, ensuring high precision.

2. Actuators and Motors: Stepper or servo motors control the machine’s axes, providing precise movement and positioning. These motors are crucial for maintaining accuracy during the manufacturing process.

3. Feedback Systems: Sensors and encoders continuously monitor the machine’s position and speed, providing real-time feedback to ensure the machine operates correctly and identifies any errors or deviations immediately.

4. Tooling: CNC machines use various cutting tools and attachments, which can be automatically changed as needed. This versatility allows them to handle a wide range of materials, including metals, plastics, and composites.

Applications of Part Machines

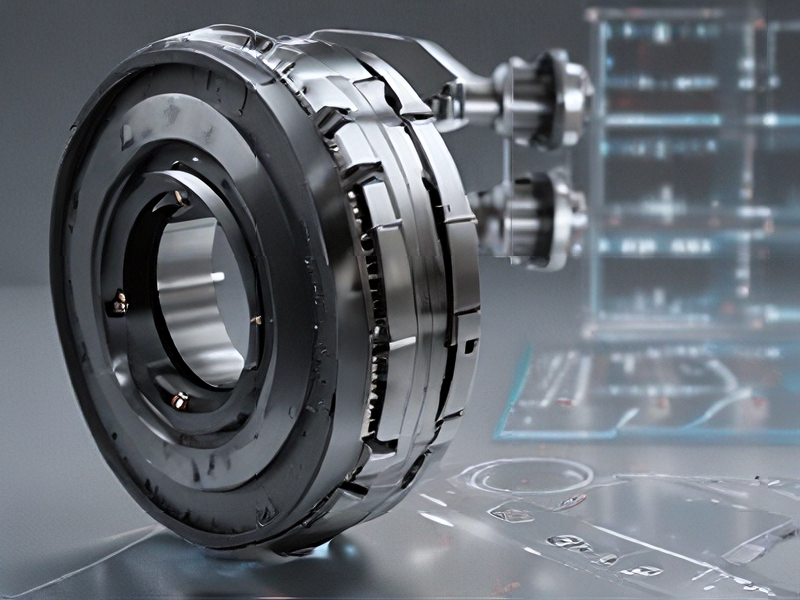

1. Automotive Industry: CNC machines produce engine components, transmission parts, and other critical automotive parts with high precision, ensuring performance and reliability.

2. Aerospace: The aerospace sector relies on CNC machines for fabricating parts that meet stringent safety and performance standards. These include turbine blades, airframe components, and complex structural parts.

3. Medical Devices: In the medical field, CNC machines manufacture implants, surgical instruments, and prosthetics with precise specifications necessary for patient safety and effectiveness.

4. Electronics: They are used in the production of circuit boards, enclosures, and other electronic components that require exact dimensions and intricate designs.

5. Consumer Products: CNC machines contribute to the production of a variety of consumer goods, from household appliances to sporting equipment, ensuring consistency and quality.

CNC technology continues to evolve, incorporating advances in automation, AI, and IoT, further enhancing its capabilities and applications across various industries.

Quality Testing Methods for part machine and how to control quality

Quality testing methods for machine parts typically involve several approaches to ensure precision and reliability:

1. Dimensional Inspection: Utilizes tools like calipers, micrometers, and coordinate measuring machines (CMMs) to verify part dimensions against specifications.

2. Visual Inspection: Examines parts for surface defects, scratches, or irregularities that could affect performance or aesthetics.

3. Functional Testing: Validates if the part operates as intended under normal conditions. This could involve stress testing, endurance testing, or functional simulations.

4. Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, X-ray inspection, or dye penetrant testing are used to detect internal defects without damaging the part.

5. Statistical Process Control (SPC): Monitors production processes using statistical methods to ensure consistency and detect deviations before they result in defective parts.

To effectively control quality:

– Establish Clear Specifications: Define precise tolerances and quality standards for each part.

– Implement Robust Inspection Procedures: Integrate regular inspections at key stages of production to catch defects early.

– Training and Certification: Ensure operators are trained in inspection techniques and regularly certified to maintain proficiency.

– Feedback Loops: Implement mechanisms to capture feedback from testing and use it to improve manufacturing processes.

By combining these methods with a proactive quality management approach, manufacturers can consistently produce high-quality machine parts that meet or exceed customer expectations.

Tips for Procurement and Considerations when Purchasing from part machine

When procuring parts or machinery, several key considerations ensure successful purchases:

1. Specifications Clarity: Clearly define technical requirements, including dimensions, materials, performance metrics, and any applicable standards or certifications needed.

2. Supplier Reliability: Assess suppliers based on reputation, past performance, references, and their ability to meet deadlines consistently.

3. Quality Assurance: Implement checks for quality control, such as inspections, certifications, or on-site audits to ensure products meet expected standards.

4. Cost-effectiveness: Balance quality with cost, considering long-term operational costs, warranties, and potential for bulk discounts.

5. Logistics and Delivery: Evaluate suppliers’ logistical capabilities, including shipping options, lead times, and ability to handle potential disruptions.

6. Compatibility and Integration: Ensure parts or machinery integrate seamlessly with existing systems or processes to avoid operational disruptions or additional costs.

7. Contractual Agreements: Clearly define terms, warranties, payment schedules, and dispute resolutions in contracts to protect both parties.

8. Risk Management: Identify and mitigate potential risks such as supply chain disruptions, regulatory changes, or technological obsolescence.

9. Environmental and Ethical Considerations: Align purchases with environmental policies and ethical standards, ensuring suppliers adhere to sustainable practices and labor laws.

10. Feedback and Continuous Improvement: Gather feedback post-purchase to inform future procurement decisions and continuously improve processes.

By adhering to these considerations, procurement processes become more streamlined, ensuring reliable and effective purchases of parts and machinery.

FAQs on Sourcing and Manufacturing from part machine in China

FAQs on Sourcing and Manufacturing from Part Machine in China

#### 1. Why source from Part Machine in China?

Part Machine offers competitive pricing, high-quality products, and advanced manufacturing capabilities. They cater to various industries with robust production processes and quick turnaround times.

#### 2. How do I ensure quality when sourcing from Part Machine?

Utilize third-party inspection services, request detailed quality control reports, and consider visiting the facility. Establish clear specifications and standards in your contracts.

#### 3. What are the common challenges in sourcing from China?

Language barriers, cultural differences, and varying quality standards. Mitigate these by hiring local sourcing agents or consultants familiar with Chinese business practices.

#### 4. How can I handle shipping and logistics?

Choose reputable freight forwarders experienced in international shipping. Understand Incoterms (International Commercial Terms) and work with suppliers to determine the best shipping methods.

#### 5. What payment methods are safe?

Letters of Credit (LC) and Trade Assurance (via Alibaba) are commonly used. They offer security by ensuring that payments are only made when agreed conditions are met.

#### 6. How do I manage intellectual property (IP) risks?

Register your IP in China and use Non-Disclosure Agreements (NDAs) with suppliers. Choose manufacturers with a good track record for IP respect.

#### 7. What should be included in the contract?

Detailed product specifications, quality standards, payment terms, delivery schedules, and penalties for non-compliance. Clear communication of expectations is crucial.

#### 8. Can I visit the manufacturing site?

Yes, visiting can be beneficial to understand the production process, establish relationships, and ensure compliance with your standards.

#### 9. How do I find a reliable supplier?

Use online platforms like Alibaba, trade shows, and industry referrals. Verify credentials and past performance through reviews and case studies.

#### 10. What are the benefits of long-term partnerships with suppliers?

Better pricing, priority in production schedules, improved communication, and higher trust, leading to consistent quality and reliability.