Technology and Applications of plastic flexible sheet

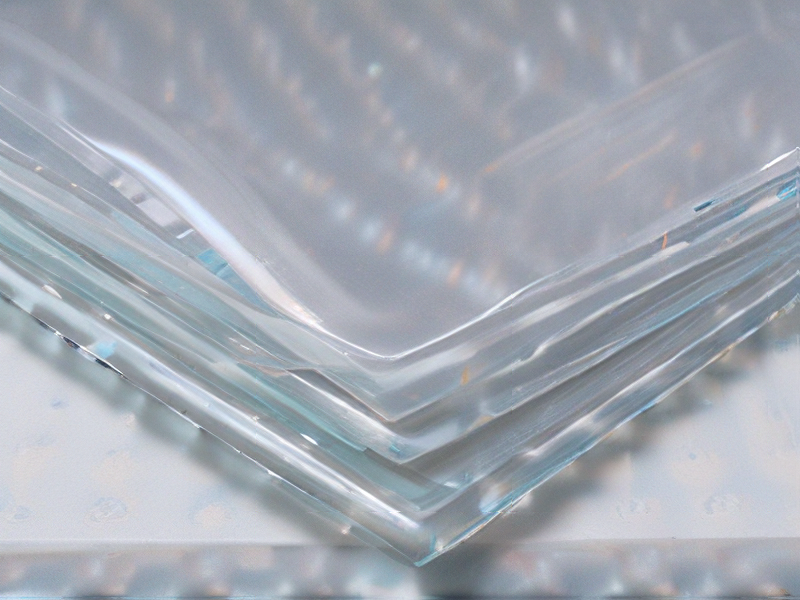

Plastic flexible sheets are versatile materials used across various industries due to their durability, flexibility, and cost-effectiveness. They are commonly made from polymers like polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), and polyethylene terephthalate (PET).

Technology:

1. Extrusion: This process involves melting plastic pellets and forcing them through a flat die to create continuous sheets. It’s widely used for producing sheets of uniform thickness.

2. Calendering: In this method, the plastic is heated and passed through rollers to form sheets. It’s particularly useful for producing thin, uniform sheets with a smooth surface.

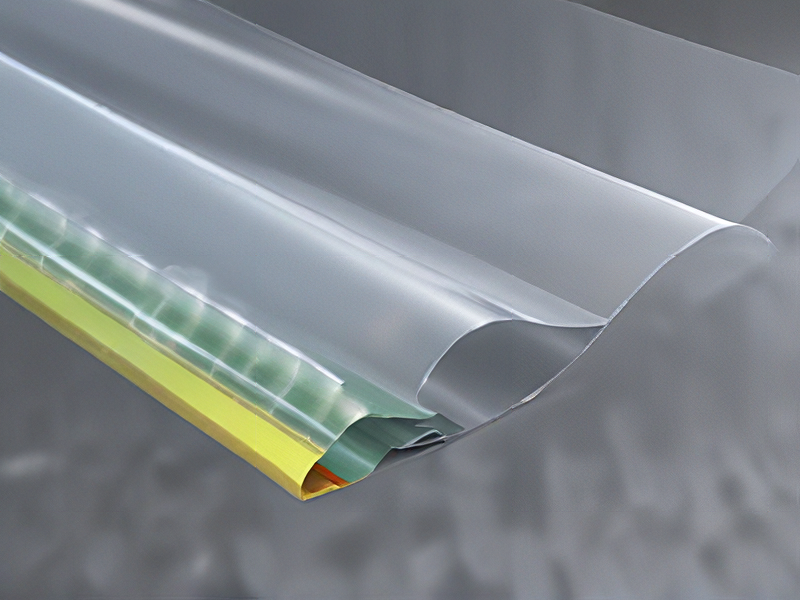

3. Lamination: Multiple layers of plastic or other materials are bonded together under heat and pressure to create composite sheets with enhanced properties like improved strength or barrier resistance.

4. Co-extrusion: This advanced technique combines different polymers in a single sheet, allowing for multiple properties in one product, such as a strong core with a soft, flexible surface.

Applications:

1. Packaging: Flexible plastic sheets are extensively used in packaging due to their lightweight, durability, and ability to protect contents from moisture and contaminants. Common products include food wraps, vacuum bags, and blister packs.

2. Construction: Used as vapor barriers, waterproof membranes, and insulation layers, these sheets help improve energy efficiency and protect buildings from moisture damage.

3. Agriculture: Mulch films, greenhouse covers, and silage wraps are examples of agricultural uses. They help in weed control, temperature regulation, and moisture retention.

4. Medical: In the healthcare sector, plastic flexible sheets are used for disposable drapes, sterile barriers, and packaging for medical devices.

5. Automotive: These sheets are used for interior trim, protective covers, and sound insulation, contributing to the comfort and durability of vehicles.

6. Consumer Goods: Products like shower curtains, tablecloths, and inflatable items rely on the flexibility and durability of plastic sheets.

In summary, the technology behind plastic flexible sheets enables their widespread application across numerous industries, highlighting their adaptability and essential role in modern manufacturing and daily life.

Quality Testing Methods for plastic flexible sheet and how to control quality

Quality testing methods for plastic flexible sheets focus on ensuring material consistency, durability, and performance. Key testing methods include:

1. Tensile Strength Test: Measures the maximum stress a material can withstand while being stretched. ASTM D882 is a common standard for this test.

2. Elongation Test: Assesses the material’s ability to stretch before breaking. This complements tensile strength testing.

3. Tear Resistance Test: Evaluates the material’s resistance to tearing, ensuring durability during use. ASTM D1004 is often used.

4. Puncture Resistance Test: Measures the sheet’s ability to withstand punctures, critical for applications requiring high durability.

5. Thickness Measurement: Ensures uniformity in sheet thickness using micrometers or ultrasonic gauges, crucial for consistent performance.

6. Moisture Vapor Transmission Rate (MVTR): Tests the permeability of the sheet to moisture, important for packaging applications. ASTM E96 is a typical standard.

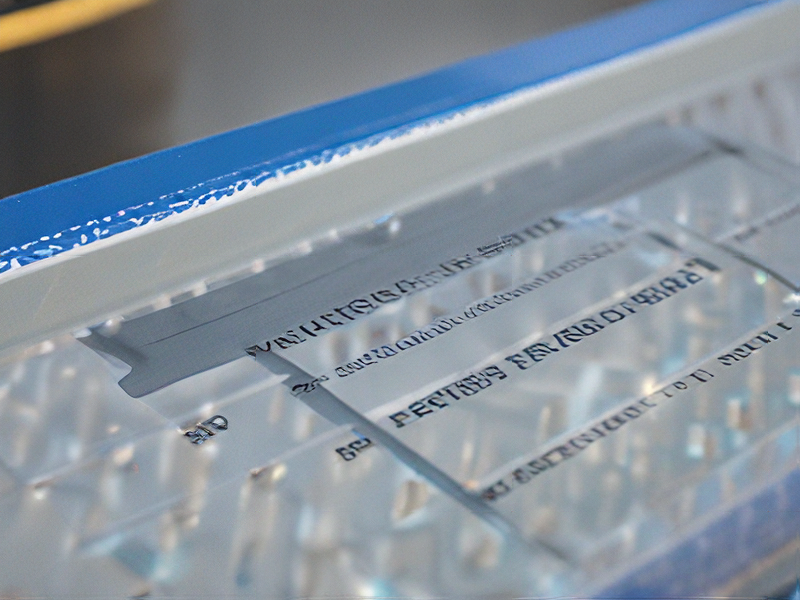

7. Optical Properties: Assess transparency, haze, and gloss using spectrophotometers to ensure the material meets visual requirements.

8. Thermal Analysis: Includes tests like Differential Scanning Calorimetry (DSC) to understand the material’s thermal properties, ensuring it performs well under various temperatures.

Quality Control Measures

1. Incoming Material Inspection: Verify the quality of raw materials before production.

2. In-Process Monitoring: Use Statistical Process Control (SPC) to monitor production parameters in real-time.

3. Finished Product Testing: Perform the above tests on final products to ensure they meet specifications.

4. Batch Sampling: Randomly select samples from each production batch for comprehensive testing.

5. Preventive Maintenance: Regularly maintain equipment to avoid malfunctions that could affect quality.

6. Training: Ensure staff are well-trained in testing procedures and quality standards.

7. Documentation and Traceability: Keep detailed records of all tests and inspections to trace any issues back to their source.

Implementing these methods and controls helps maintain high quality and consistent performance of plastic flexible sheets.

Tips for Procurement and Considerations when Purchasing from plastic flexible sheet

When procuring plastic flexible sheets, several key considerations can streamline the purchasing process and ensure optimal outcomes:

1. Quality Standards: Verify the plastic sheet’s compliance with industry standards (e.g., ASTM or ISO) to ensure it meets your durability and performance requirements.

2. Material Specifications: Understand the specific type of plastic (e.g., PVC, PET, polyethylene) and its thickness, transparency, and flexibility needed for your application.

3. Supplier Reliability: Choose suppliers with a proven track record for quality, reliability in delivery, and customer service. Obtain references or check reviews if possible.

4. Cost Efficiency: Balance quality and cost-effectiveness. Consider long-term durability and maintenance costs alongside initial purchase price.

5. Environmental Impact: Assess the environmental footprint of the plastic sheets, considering factors like recyclability and sustainability certifications.

6. Customization Options: Determine if customization (e.g., size, color, printing) is available to meet specific project requirements.

7. Testing and Samples: Request samples for testing compatibility with your processes and to validate performance claims before committing to larger purchases.

8. Logistics and Storage: Plan for transportation and storage requirements, considering factors like bulk packaging, shelf life, and handling instructions.

9. Contractual Agreements: Clearly define terms regarding warranties, returns, and dispute resolution to protect your interests.

10. Future Needs: Anticipate future demand fluctuations or new applications to ensure scalability and continuity of supply.

By addressing these considerations, you can make informed decisions when procuring plastic flexible sheets that align with your operational needs and sustainability goals.

FAQs on Sourcing and Manufacturing from plastic flexible sheet in China

When sourcing and manufacturing plastic flexible sheets in China, here are key FAQs:

1. What are the typical materials used?

Plastic flexible sheets often use materials like PVC, PET, PE, or PP due to their flexibility and durability.

2. How can I find reliable suppliers?

Utilize online platforms like Alibaba or Global Sources to search for suppliers with verified credentials and positive reviews. Request samples and visit trade shows for direct interaction.

3. What should I consider when selecting a supplier?

Look for suppliers with experience in plastic sheet manufacturing, certifications (ISO, FDA if applicable), production capacity, quality control measures, and their ability to meet your specific requirements.

4. What are common manufacturing processes?

Processes include extrusion, calendaring, and lamination. Verify that the supplier uses appropriate techniques for your desired specifications.

5. How can I ensure product quality?

Conduct regular inspections during production and before shipment. Consider hiring a third-party inspection service. Clearly define quality standards and communicate them with your supplier.

6. What about logistics and shipping?

Discuss shipping terms (FOB, CIF) and logistics arrangements in advance. Factor in lead times and potential delays, especially considering global supply chain challenges.

7. Are there environmental considerations?

Ensure compliance with environmental regulations (RoHS, REACH). Inquire about the supplier’s waste management practices and commitment to sustainability.

8. How do I handle intellectual property concerns?

Sign confidentiality agreements and protect your designs with patents or trademarks if necessary. Be cautious about sharing sensitive information.

9. What are payment terms typically like?

Negotiate payment terms that balance your cash flow needs with supplier expectations. Consider using secure payment methods to minimize risks.

10. How can I resolve disputes if they arise?

Include dispute resolution clauses in contracts. Maintain clear communication and document all agreements and changes.

Navigating these FAQs will help ensure a smoother sourcing and manufacturing process for plastic flexible sheets in China while mitigating risks and maximizing quality control.