Understanding Reliable Position Tolerance in SourcifyChina Factories for Precision Manufacturing

In this concise guide, we delve into how SourcifyChina ensures reliable position tolerance in their factory operations, critical for precision manufacturing and maintaining high quality standards. Perfect for businesses seeking dependable production partners in China.

Choosing SourcifyChina factory for purchasing position tolerance components offers multiple benefits:

First, SourcifyChina ensures stringent quality control measures, which guarantee that tolerances meet precise specifications. This leads to consistent product performance, enhancing customer satisfaction and reducing post-production issues.

Second, the factory leverages advanced technologies and skilled professionals to provide accurate and reliable components. This capability ensures optimal fit and function in various applications, promoting operational efficiency.

Moreover, SourcifyChina’s strategic location in China’s manufacturing hub allows for cost-effective production and timely delivery. This efficiency is beneficial for businesses requiring quick turnaround times and competitive pricing.

Additionally, the factory’s excellent customer service focuses on clear communication and support throughout the purchasing process. This partnership fosters trust and reliability, critical for long-term business engagements.

Finally, SourcifyChina offers customized solutions to meet unique requirements, making it an ideal partner for diverse industrial needs. This flexibility ensures each project receives the specialized attention it deserves.

Position tolerance refers to the allowable deviation of a feature’s location from its true position. It’s crucial in manufacturing for ensuring parts fit and function properly. There are various types and options available for position tolerance to cater to different design and functionality requirements.

– True Position Tolerance: Measures the deviation of a feature from its exact location, usually represented by a cylindrical tolerance zone.

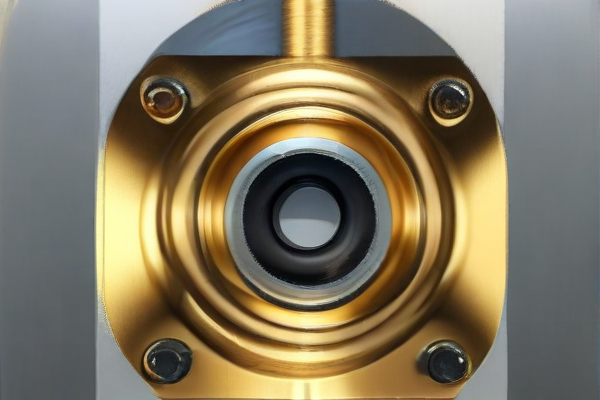

– Concentricity: Ensures the central axes of two or more features are coincident.

– Symmetry: Controls the symmetry of a feature about a datum plane or axis.

– Parallelism: Ensures a feature is parallel to a datum plane or axis.

– Perpendicularity: Ensures a feature is perpendicular to a datum plane or axis.

– Angular Tolerance: Controls the angle between a feature and a datum plane or axis.

– Runout: Measures the circular runout of a rotating part relative to a datum axis.

– Circularity (Roundness): Ensures the feature’s surface is equidistant from its center, maintaining a perfect circle.

– Cylindricity: Controls the form of a cylindrical feature to ensure it is equally spaced from its central axis.

– Flatness: Ensures a feature’s surface is within two parallel planes.

These options provide flexibility in specifying the allowable deviations, enhancing the precision and functionality of the manufactured parts.

Position tolerance is crucial in ensuring that the location of a feature on a part meets specified accuracy requirements. It is widely used in manufacturing and engineering to enhance quality and precision.

– Ensures proper assembly of parts by maintaining positional accuracy.

– Enhances product performance by aligning components correctly.

– Reduces manufacturing defects and rework costs.

– Facilitates interchangeability in mass production.

– Supports compliance with industry standards and regulations.

– Improves the functionality of mechanical and electronic assemblies.

– Aids in achieving tight tolerances in precision engineering.

– Helps in quality control and inspection processes.

– Assists in the design and analysis of complex assemblies.

– Ensures reliability in critical applications like aerospace and automotive industries.

– Optimizes the use of materials by minimizing waste.

– Enables accurate fit and function of mating parts.

– Assists in maintaining consistent production quality.

– Enhances the longevity and durability of products.

– Contributes to efficient and accurate CAD/CAM processes.

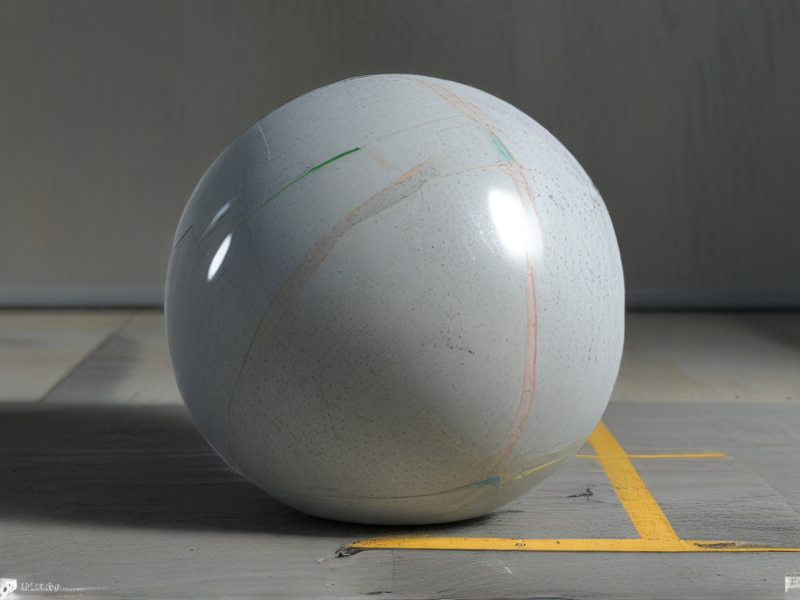

SourcifyChina is a trusted partner in precision manufacturing, offering high-quality position tolerance solutions. These services guarantee that components fit together correctly, essential for industries requiring exact specifications. Position tolerance is crucial in various fields like aerospace, automotive, and machinery, ensuring parts align perfectly in assemblies.

The materials used for position tolerance manufacturing at SourcifyChina vary widely, depending on client requirements. They range from metals such as aluminum, steel, and titanium to high-grade polymers. Each material is selected based on its properties, including strength, flexibility, and resistance to environmental factors, ensuring the end product meets rigorous standards.

Advanced technologies enable SourcifyChina to achieve exceptional accuracy in position tolerance. Computer Numerical Control (CNC) machines, Coordinate Measuring Machines (CMM), and precision laser tools are employed to meet tight tolerances. These technologies ensure that every component produced adheres to the specified limits, minimizing errors and reducing waste.

Quality control is integral to SourcifyChina’s services. Strict inspections are conducted at every stage of production to ensure components meet the exact tolerances required. This meticulous attention to detail ensures that clients receive products that function seamlessly in their intended applications, enhancing overall performance and reliability.

In summary, SourcifyChina excels in providing precise position tolerance services using a variety of materials tailored to specific industrial needs. Advanced machining technologies and rigorous quality control processes underline its commitment to delivering high-quality, reliable components. This dedication makes SourcifyChina a leader in the field, ensuring their clients’ products meet the highest standards of accuracy and performance.

SourcifyChina’s position tolerance quality control in manufacturing ensures precision. This method measures how accurately a feature is located, enhancing the final product’s quality and consistency. Rigorous adherence to position tolerance minimizes errors, boosting customer satisfaction.

In the beginning stages, engineers establish tolerance benchmarks. They identify critical features and define allowable variations. Sophisticated software tools aid in creating precise designs, ensuring components meet stringent specifications before production starts.

During the manufacturing phase, advanced machinery and skilled technicians maintain these established tolerances. Regular inspections and calibrations guarantee machinery operates within the defined limits. Implementing stringent protocols reduces deviations and material waste.

Post-production, quality assurance teams rigorously inspect finished products. Utilizing Coordinate Measuring Machines (CMMs) and other precision instruments, they verify adherence to specified tolerances. Any deviations prompt immediate corrective action and analysis to prevent recurring issues.

Continuous feedback loops and data analysis refine the process constantly. SourcifyChina leverages data-driven insights from each production run to enhance tolerance levels and manufacturing protocols. This commitment to precision and quality ensures every product meets high standards.

SourcifyChina’s focus on position tolerance spans the entire manufacturing cycle. By prioritizing quality control and continual improvement, they maintain their reputation for delivering reliable, precision-engineered products. Their methodical approach ensures each component functions flawlessly in its intended application, underscoring their commitment to excellence in manufacturing.

SourcifyChina offers exceptional position tolerance capabilities in manufacturing. Their state-of-the-art technology ensures precise component placement, essential for high-quality production outcomes. This capability is critical for industries requiring meticulous accuracy.

The company employs advanced CNC machines and laser-guided systems to maintain tight position tolerances. These technologies enable the production of complex geometries with minimal deviation from the specified dimensions, enhancing reliability and performance.

SourcifyChina’s skilled workforce is adept at managing position tolerance specifications. Their rigorous training programs ensure that every technician can execute operations with high precision, thereby meeting stringent international standards and customer requirements.

One of the significant advantages of SourcifyChina is their robust quality control system. Utilizing precision measuring instruments, they conduct thorough inspections to ensure each part adheres to tolerance specifications, thereby reducing rejection rates and increasing customer satisfaction.

In addition to high-tech machinery and skilled personnel, SourcifyChina prioritizes continuous improvement. They regularly update their processes and equipment to stay ahead in the competitive market, thereby consistently delivering superior position tolerance capabilities.

Their expertise in position tolerance also extends to custom projects. Clients can specify unique requirements, and SourcifyChina will develop tailored solutions, ensuring the final products meet or exceed expectations. This flexibility is particularly beneficial for industries with specialized needs.

SourcifyChina’s commitment to precision manufacturing ensures that each project is completed with the utmost accuracy. Their emphasis on technology, skill, and continuous improvement makes them a leading choice for companies requiring stringent position tolerance in their manufacturing processes.

Position tolerance, a key aspect in geometric dimensioning and tolerancing (GD&T), ensures the accurate location of features in manufactured parts, enhancing assembly efficiency and product quality.

Benefits of Position Tolerance:

– Improved Assembly: Ensures parts fit together precisely, reducing assembly issues and rework.

– Increased Quality: Enhances the functionality and reliability of the final product.

– Cost Savings: Minimizes material waste and rework, leading to reduced manufacturing costs.

– Enhanced Interchangeability: Allows for parts to be easily replaced or interchanged without fitting issues.

– Better Communication: Provides clear and concise specifications, reducing misunderstandings among design, production, and inspection teams.

– Simplified Inspection: Facilitates easier and more accurate measurement and verification of parts.

– Flexibility in Design: Allows designers to specify acceptable variation, giving more flexibility in manufacturing processes.

Position Tolerance Feature Overview:

Position tolerance is a critical aspect of geometric dimensioning and tolerancing (GD&T) that controls the location accuracy of features on a part.

– Defines Location Precision: Ensures features are in their exact intended positions.

– Enhances Interchangeability: Guarantees parts fit together properly by maintaining consistent feature placement.

– Improves Quality Control: Provides clear standards for inspection and measurement.

– Minimizes Assembly Issues: Reduces the risk of part misalignment and assembly errors.

– Supports Complex Designs: Facilitates the creation of intricate parts by specifying precise tolerances.

– Utilizes a Datum System: Relies on reference points, lines, or planes to define feature positions.

– Encourages Efficient Production: Helps streamline manufacturing processes by reducing variations.

– Aids in Compliance: Aligns with standardized engineering practices and specifications.

– Supports Flexibility: Allows for some degree of tolerance, accommodating minor deviations without compromising functionality.

– Reduces Waste: By ensuring components meet precise criteria, it minimizes the production of non-conforming parts, leading to less material wastage.

SourcifyChina is a renowned company specializing in custom products and project management, especially in precision engineering. Their expertise in position tolerance ensures accurate and reliable components for various industries.

Through advanced manufacturing techniques, SourcifyChina meets stringent position tolerance requirements. This guarantees the perfect alignment and fit of all parts, crucial for high-performance machinery and tools.

Their commitment to precision extends to every custom project, regardless of complexity. They work closely with clients to understand specific needs, ensuring that each product meets exact specifications and quality standards.

In addition to position tolerance, SourcifyChina excels in material selection and finishing processes. They provide tailored solutions that enhance both durability and functionality, without compromising on aesthetics.

With a strong focus on customer satisfaction, SourcifyChina offers comprehensive support from initial design through to final production. Their skilled team ensures seamless project execution at competitive prices.

Partnering with SourcifyChina means getting access to innovative solutions and cutting-edge technologies tailored to your unique requirements. Trust them to deliver meticulously crafted products that set the benchmark in precision and performance.

SourcifyChina is an esteemed company specializing in precision manufacturing and quality control services with a focus on achieving stringent position tolerances for a diverse range of industries. Renowned for its commitment to excellence, SourcifyChina employs advanced technology and state-of-the-art machinery to ensure that all components meet the exacting standards of their clients. The company utilizes a rigorous quality assurance process, incorporating tools such as coordinate measuring machines (CMM) and laser scanners to verify that every product conforms to specified positional tolerances, which is critical for applications requiring high accuracy and reliability. With a team of highly skilled engineers and quality control experts, SourcifyChina not only meets but often exceeds customer expectations in terms of precision, timely delivery, and cost-effectiveness. As a trusted partner in manufacturing solutions, SourcifyChina continues to build a strong reputation for reliability and innovation in the global market.

Position tolerance is a critical concept in Aerospace, Defense, and Marine (ADM) industries, where precision and reliability are paramount. In aerospace applications, position tolerance ensures that critical components such as engine mounts, landing gear, and control surfaces are assembled with extreme accuracy. This precision is vital for maintaining aerodynamic efficiency, structural integrity, and safety. For instance, in the construction of an aircraft fuselage, the exact positioning of rivet holes and fasteners is essential to distribute stress uniformly and avoid structural weaknesses that could lead to catastrophic failures during flight. The use of advanced metrology tools and computer-aided design (CAD) systems helps engineers achieve these tight tolerances, ensuring that each part fits perfectly within the specified geometric limits.

In defense and marine sectors, position tolerance is equally crucial for the proper functioning of complex systems and assemblies. For example, in the production of submarines, the alignment of propulsion systems, torpedo tubes, and navigational equipment must adhere to stringent position tolerances to ensure optimal performance and stealth capabilities. Similarly, in the defense industry, precise positioning of components in weaponry and surveillance systems, such as missile guidance assemblies and radar units, is necessary to achieve superior accuracy and reliability. Tight control over position tolerances translates to higher quality and reliability of these systems, ultimately enhancing their effectiveness in critical missions. Manufacturers employ state-of-the-art machining techniques, quality control procedures, and rigorous testing to meet the exacting standards required in these high-stakes environments.

Position tolerance is an essential concept in the automotive industry, where precision and durability are paramount. In the assembly of vehicle components, such as engine parts, transmission systems, and suspension elements, position tolerance ensures that each part fits correctly within a designated framework. Accurate position tolerance prevents excessive wear, vibration, and misalignment, thereby enhancing overall vehicle performance and longevity. For instance, in an engine’s cylinder block, the position tolerance of the bore holes for pistons and crankshafts is critical to ensure smooth operation and efficient power transfer. Tight control of these tolerances minimizes the risk of mechanical failure, reduces noise, and promotes fuel efficiency, contributing to an optimal driving experience.

In the electronics industry, position tolerance is equally vital for the assembly and functionality of devices ranging from consumer electronics to sophisticated aerospace systems. Printed Circuit Boards (PCBs) illustrate the importance of position tolerance, as the precise placement of electronic components like resistors, capacitors, and integrated circuits is crucial for the device to function properly. Inaccurate positioning can lead to electrical shorts, signal interference, or complete circuit failure. Moreover, in the manufacturing of connectors and mating interfaces, position tolerance ensures reliable connections, crucial for data transfer and signal integrity. As electronic devices become increasingly compact and complex, maintaining precise position tolerance during assembly has become critical, directly impacting the device’s reliability, performance, and lifespan. Thus, in both automotive and electronics sectors, position tolerance plays a pivotal role in ensuring the quality and dependability of the final products.

Position tolerance is a crucial concept in construction, playing a significant role in ensuring that structural elements are accurately placed and aligned. It specifies the allowable deviation from a specified position, which is critical when considering the alignment of beams, columns, and anchor bolts in building frameworks. Accurate position tolerance ensures that loads are distributed correctly and that components fit together seamlessly, reducing the risk of structural failures. For example, in the installation of steel beams, stringent position tolerances are necessary to maintain the integrity of the overall structure. A slight misalignment can lead to uneven load distribution, potentially causing structural weaknesses or failures. Therefore, adherence to position tolerances is essential to maintain safety, functionality, and aesthetic standards in construction projects.

In the energy sector, position tolerance is equally important, particularly in the installation and maintenance of equipment like turbines, solar panels, and pipeline systems. For wind turbines, precise positioning of the tower and blades is crucial for optimal energy capture and conversion. Misalignment due to poor position tolerance can lead to inefficient operation and increased wear and tear, ultimately reducing the lifespan and performance of the turbines. Similarly, in solar energy, the accuracy in the positioning of photovoltaic panels influences their exposure to sunlight and, consequently, their efficiency in energy production. Pipeline systems also rely on strict position tolerances to ensure that pipes are aligned correctly, preventing leaks and ensuring smooth flow of gas or liquids. In all these applications, maintaining specified position tolerances is fundamental to optimizing efficiency, safety, and longevity of energy systems.

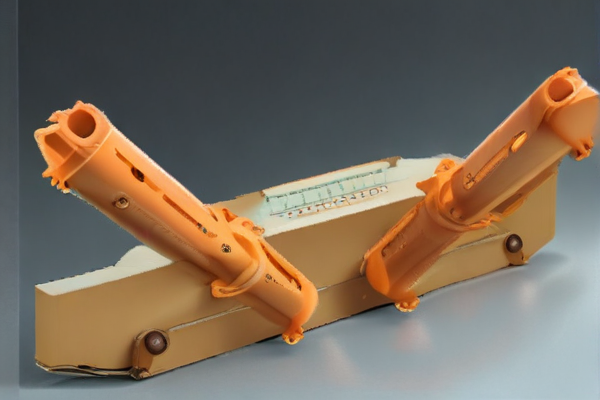

Position tolerance is a critical concept in the industrial equipment industry, ensuring the precise placement of components within complex machinery. This geometric dimensioning and tolerancing (GD&T) specification defines the allowable variation in the location of a feature from its exact, theoretical position. By employing position tolerance, manufacturers can achieve high levels of accuracy and consistency, which is vital for the interoperability and performance of industrial equipment. For instance, in the assembly of large-scale machinery such as turbines, conveyors, or robotic arms, position tolerance ensures each component fits together perfectly, thus minimizing the risk of operational failures and enhancing the overall efficiency and reliability of the system.

Moreover, position tolerance plays a pivotal role in the maintenance and lifecycle management of industrial equipment. Accurate initial assembly, facilitated by stringent adherence to position tolerance specifications, simplifies future maintenance and replacement of parts. When components are manufactured to precise tolerances, they can be interchanged without extensive modifications or adjustments, reducing downtime and operational disruptions. In industries where precision is paramount, such as aerospace, automotive, and semiconductor manufacturing, position tolerance allows for the meticulous control necessary to maintain strict quality standards. This facilitates not only the smooth operation of machinery but also extends the service life of the equipment by reducing wear and tear caused by misalignments and improper fitment.

Position tolerance is a critical aspect in the manufacturing and application of medical devices, ensuring the precise and reliable performance of components that often interact with the human body. In medical devices such as prosthetics, implants, and surgical instruments, even the slightest deviation in the positioning of parts can lead to malfunctions, discomfort, or severe complications for patients. Position tolerance, governed by geometric dimensioning and tolerancing (GD&T) principles, allows engineers to specify the acceptable range within which a feature or part can vary from its true position. This ensures that components fit perfectly and function as intended, underlining the importance of precision engineering in medical device production.

Moreover, maintaining position tolerance is vital for meeting stringent regulatory requirements imposed by health authorities like the FDA and ISO. These regulations mandate strict adherence to quality and safety standards in medical devices. For instance, the accurate placement of electrodes in a cardiac pacemaker or the alignment of contact points in a joint implant directly impacts device efficacy and patient outcomes. Advanced manufacturing technologies such as CNC machining and laser cutting are employed to achieve high levels of positional accuracy. In essence, the application of position tolerance ensures that medical devices are not only safe and functional but also deliver optimal performance, thereby enhancing patient care and trust in medical technology.

Position tolerance is a critical concept in machining and manufacturing, ensuring that parts fit together with precision in assemblies. This geometric dimensioning and tolerancing (GD&T) specification defines the allowable deviation from the exact position of a feature, such as a hole or a slot, relative to a datum. By implementing position tolerance, manufacturers can guarantee that components not only fit together accurately but also function correctly and consistently. During the machining process, applying position tolerance standards minimizes errors caused by machine limitations, material imperfections, or human factors. As a result, it exceeds mere dimensional accuracy by ensuring a part’s positional accuracy, thereby promoting higher-quality final products.

In the context of manufacturing, position tolerance plays an essential role in mass production and assembly lines. It enables the consistent interchangeability of parts, which is critical for maintaining production efficiency and minimizing downtime. For instance, automotive and aerospace industries often rely on stringent position tolerance standards to achieve the high degree of reliability and safety required in these fields. By using coordinate measuring machines (CMM) and other advanced inspection methods, manufacturers can verify that each part conforms to its positional specifications. This holistic approach not only reduces waste and rework but also enhances overall product performance, leading to increased customer satisfaction. Position tolerance, therefore, is indispensable for precision, efficiency, and quality in modern machining and manufacturing applications.

Sure, here is a list of Frequently Asked Questions (FAQ) along with their answers for manufacturing “position tolerance quality work” from SourcifyChina factory:

Q: What is position tolerance in manufacturing?

A: Position tolerance refers to the permissible variation in the location of a feature from its exact position. It ensures that parts will fit together and function correctly in an assembly.

Q: Why is position tolerance important for quality work?

A: Position tolerance is critical as it guarantees consistency and compatibility between different parts, reducing errors and ensuring the final product meets all design specifications.

Q: How does SourcifyChina ensure high standards in position tolerance?

A: SourcifyChina employs advanced precision machining and rigorous quality control processes, including regular inspections and state-of-the-art measurement tools, to ensure all products adhere to specified position tolerances.

Q: What types of measurement tools are used for inspecting position tolerance at SourcifyChina?

A: We use high-precision instruments like Coordinate Measuring Machines (CMM), optical comparators, and laser scanners to verify position tolerances.

Q: Can SourcifyChina handle complex tolerance requirements?

A: Absolutely. Our expert engineers are skilled in working with complex geometries and tight tolerances, ensuring every part meets detailed specifications.

Q: What materials can SourcifyChina work with while maintaining strict position tolerances?

A: We handle a wide range of materials, including metals, plastics, and composites, while maintaining strict position tolerances to ensure high-quality outputs.

Q: How does SourcifyChina address any position tolerance defects found during inspections?

A: Any defects identified during inspections are promptly addressed. We analyze the root cause and implement corrective actions to prevent recurrence, ensuring continuous quality improvement.

Q: How can I communicate my specific tolerance requirements to SourcifyChina?

A: You can detail your requirements in design documents and technical drawings. Our team will review these specifications and ensure all tolerances are met during production.

Q: What industries does SourcifyChina serve?

A: We serve a diverse range of industries including automotive, aerospace, medical, and consumer electronics, ensuring all sector-specific tolerance requirements are met.

Q: How can I get a quote for manufacturing with precise position tolerances?

A: You can contact us with your project details and specifications. Our team will provide a detailed quote based on your requirements.

Position tolerance is a critical consideration in precision manufacturing, and collaborating with a reputable factory like SourcifyChina can significantly enhance your production quality. Here are some essential tips for ensuring effective position tolerance:

1. Clearly Define Tolerance Requirements: Provide detailed drawings and specifications with precise tolerance requirements. This leaves no room for ambiguity and ensures that the factory understands and adheres to your standards.

2. Choose the Right Manufacturing Process: Different manufacturing processes have varying capabilities in terms of position tolerance. CNC machining, for example, generally offers tighter tolerances than casting or forging. Consult with the factory to determine the best method.

3. Material Selection: The choice of material can impact the achievable position tolerance. Work with the factory to select materials that not only meet your design requirements but also support finer tolerances.

4. Inspection and Measurement Tools: Ensure that the factory employs advanced inspection and measurement tools, such as Coordinate Measuring Machines (CMM), to verify position tolerances accurately.

5. Quality Control Protocols: Establish robust quality control protocols. This includes in-process checks and final inspections to catch any deviations early and reduce the risk of defective parts reaching you.

6. Regular Communication: Maintain open and regular communication with SourcifyChina’s team. Regular updates and feedback loops can help in addressing any issues promptly and maintaining quality standards.

7. Prototyping and Pilot Runs: Conduct prototyping and pilot runs to identify any potential tolerance issues before full-scale production. This step can save time and cost by allowing early adjustments.

8. Supplier Audits: Periodic audits of the factory’s processes and equipment can help ensure compliance with your position tolerance requirements.

By following these tips and leveraging SourcifyChina’s expertise, you can achieve superior position tolerance in your manufacturing projects, leading to high-quality end products.

Sure, here’s a concise FAQ for sourcing position tolerance from the SourcifyChina factory:

1. What is position tolerance?

Position tolerance stipulates the allowable deviation for the location of a feature on a part, ensuring components fit and function together as intended.

2. Why should I source position-tolerant parts from SourcifyChina?

SourcifyChina offers high-precision manufacturing capabilities, competitive pricing, and strict quality control, ensuring your parts meet stringent tolerance requirements.

3. What is SourcifyChina’s typical tolerance range?

Our standard position tolerance range is within ±0.01 to ±0.05 mm. We can achieve tighter tolerances upon request, depending on the project’s complexity and material.

4. How does SourcifyChina ensure tolerance compliance?

We employ advanced measurement techniques and equipment, such as CMM (Coordinate Measuring Machines), and adhere to ISO quality standards for consistent adherence to specified tolerances.

5. How do I specify position tolerance in my order?

Include detailed technical drawings and tolerance specifications in your RFQ (Request for Quote). Ensure all critical dimensions and tolerances are clearly marked.

6. What materials can SourcifyChina work with?

We handle a wide range of materials, including metals (aluminum, steel, titanium) and plastics (ABS, nylon, PEEK). Contact us for specifics.

7. What is the lead time for position-tolerant parts?

Lead times vary based on part complexity, volume, and material. Generally, our lead times range from 2 to 6 weeks.

8. Can SourcifyChina provide prototypes for position-tolerant parts?

Yes, we offer prototyping services to validate designs and ensure they meet specified tolerances before full-scale production.

9. Are there any additional costs for tighter tolerances?

Tighter tolerances can increase manufacturing complexity, impacting costs. We’ll provide a detailed quote reflecting any additional expenses.

10. How can I contact SourcifyChina for more information?

You can reach out via our website contact form, email, or phone to discuss your specific requirements and obtain a quote.

When sourcing position tolerance information from SourcifyChina or any factory, follow these tips to ensure clarity and accuracy:

1. Define Your Requirements Clearly:

– Specify the exact position tolerance requirements in your technical drawings and specifications. Use standardized GD&T (Geometric Dimensioning and Tolerancing) symbols to avoid ambiguity.

2. Communicate Directly:

– Engage in direct communication with the factory. Use video calls, emails, and instant messaging to discuss your requirements thoroughly. Ensure there is no room for misinterpretation.

3. Provide Samples:

– If possible, provide physical or digital samples of previous products that meet your position tolerance standards. This serves as a tangible reference for the factory.

4. Request Detailed Documentation:

– Ask for detailed process documentation and quality control measures the factory will use to achieve the specified position tolerance. This includes inspection reports and measurement techniques.

5. Conduct Audits:

– Perform on-site or virtual audits of the factory’s facilities and processes. Ensure they have the necessary equipment and expertise to meet your tolerance requirements.

6. Pilot Runs and Prototyping:

– Before committing to full-scale production, request pilot runs or prototype samples. Inspect these initial outputs to ensure they meet your position tolerance specifications.

7. Quality Assurance Agreements:

– Establish clear quality assurance agreements that include position tolerance as a key criterion. Specify the penalties for non-compliance to ensure accountability.

8. Use Third-Party Inspection Services:

– Engage third-party inspection services to verify that the position tolerance requirements are consistently met throughout production.

9. Maintain Open Communication:

– Keep an open line of communication for ongoing projects. Regular updates and feedback loops help address any issues promptly.

10. Cultural Sensitivity:

– Be mindful of cultural differences in communication and business practices. A respectful and understanding approach fosters better collaboration.

By following these steps, you can effectively source position tolerance information and ensure the factory meets your precise specifications.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.