“SourcifyChina” Factory is a leading provider of precision medical machining in China, known for top-notch quality and technological innovation. With a dedicated team of experts, the factory ensures that strict international healthcare standards are met.

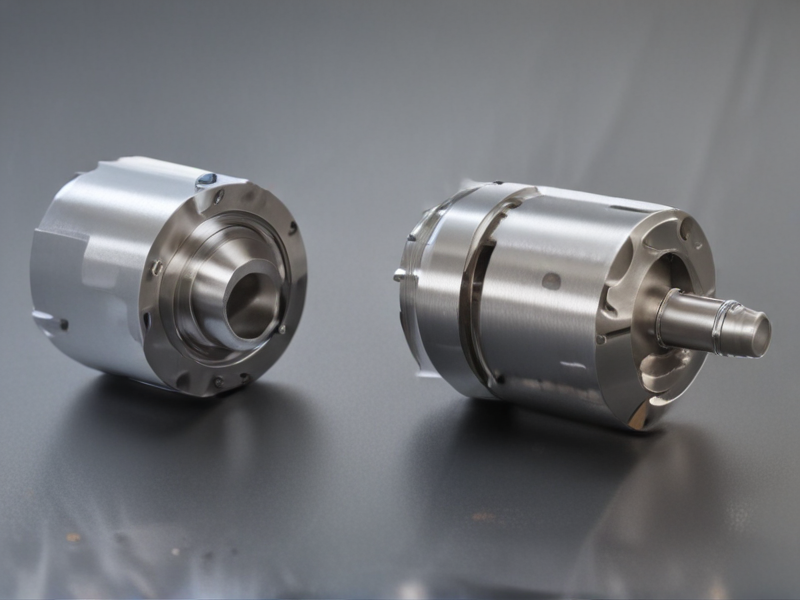

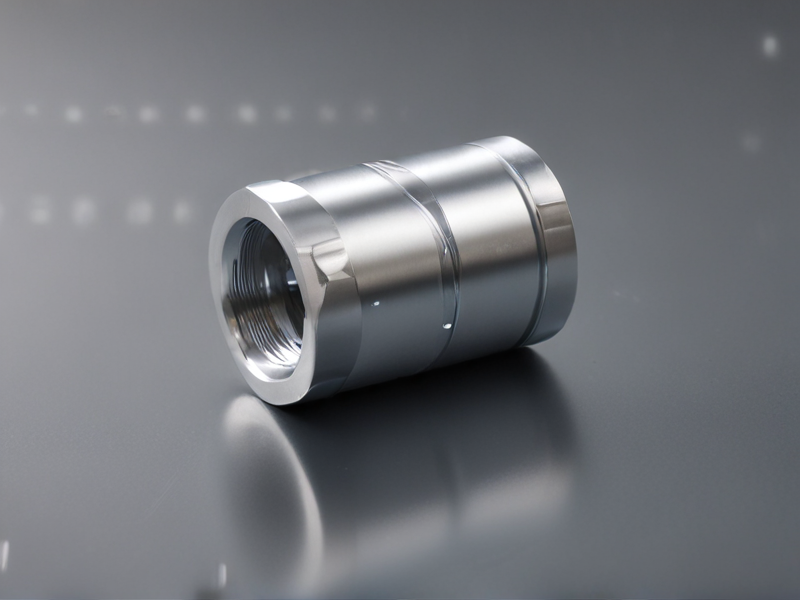

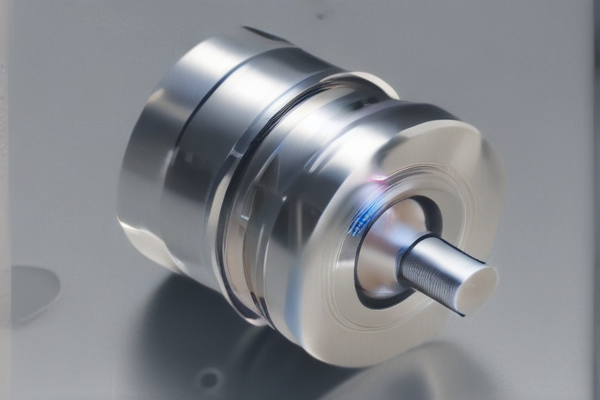

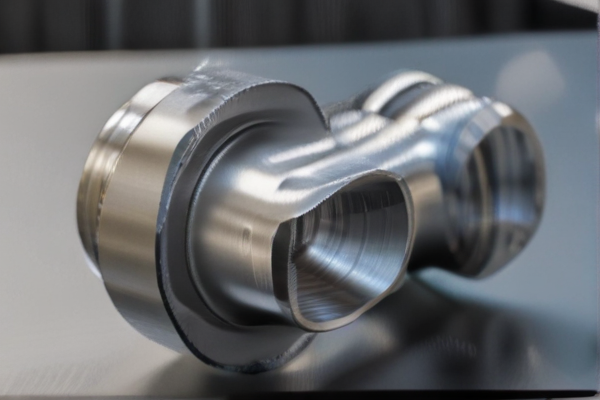

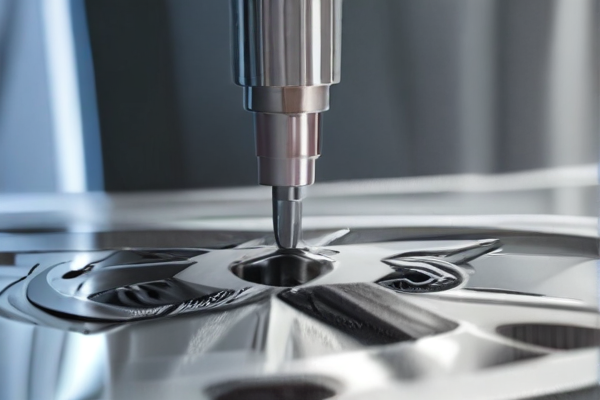

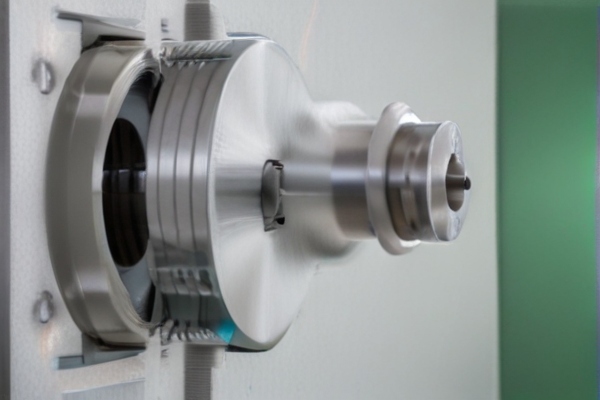

Furthermore, the factory leverages cutting-edge CNC machinery and advanced inspection equipment. This ensures exceptional precision in every component, making them ideal for critical medical applications where accuracy is paramount.

Competitive pricing is another hallmark of “SourcifyChina” Factory. Despite offering world-class machining services, the company remains committed to providing cost-effective solutions, making it an attractive choice for buyers aiming to balance quality and budget.

Customer support is also a priority. “SourcifyChina” Factory offers personalized service, from the initial consultation to post-delivery support, ensuring a seamless procurement process. Their multilingual team bridges any communication gaps, catering to global clients efficiently.

Environmental considerations are integral to the factory’s operations. Employing eco-friendly practices and sustainable materials, “SourcifyChina” is committed to minimizing its carbon footprint, aligning with the latest global environmental standards and contributing to corporate social responsibility.

In summary, choosing “SourcifyChina” Factory for precision medical machining means opting for unparalleled quality, advanced technology, competitive pricing, exceptional customer support, and eco-conscious practices. Their comprehensive approach ensures that clients receive not just components, but complete, reliable solutions tailored to their specific medical needs.

Precision medical machining is a critical process in manufacturing components used in medical devices and implants, requiring high accuracy and tight tolerances. It utilizes advanced technologies to produce parts that meet stringent healthcare standards.

– CNC Machining: Automated control of machining tools using computer programming.

– Micro-Machining: Production of tiny components often used in minimally invasive surgical instruments.

– Laser Machining: Utilizes laser technology for precise cutting and engraving, ideal for delicate materials.

– 5-Axis Machining: Enhances capability to produce complex shapes and geometries essential for medical implants.

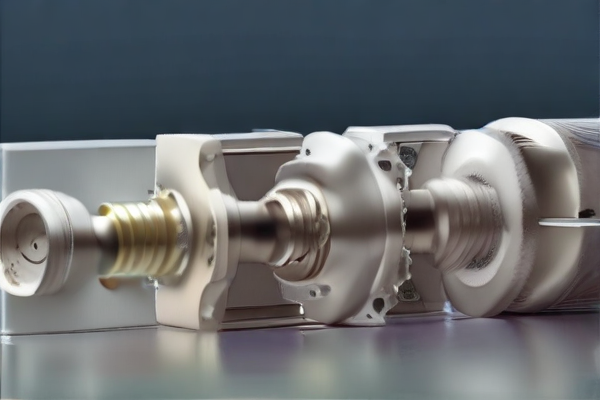

– Electrical Discharge Machining (EDM): Advanced method for manufacturing intricate parts with fine details.

Materials Commonly Used:

– Titanium: High strength, corrosion-resistant, and biocompatible.

– Stainless Steel: Durable and commonly used for surgical instruments.

– Aluminum: Lightweight and used in non-implantable medical devices.

– Biocompatible Plastics: Useful for disposable medical products and some implantable devices.

Quality Assurance Measures:

– CMM (Coordinate Measuring Machines): For precise dimensional verification.

– Cleanroom Manufacturing: Ensures parts are produced in a contaminant-free environment.

Technological Innovations:

– Additive Manufacturing (3D Printing): Enables rapid prototyping and custom components.

– Robotics: Increases precision and efficiency in manufacturing processes.

Custom Solutions:

– Tailored machining processes specific to patient needs and medical applications.

Key Applications:

– Orthopedic Implants: Knees, hips, and spine implants.

– Cardiovascular Devices: Stents, heart valves, and pacemaker casings.

– Dental Components: Dental implants and orthodontic braces.

Precision medical machining is crucial for manufacturing intricate medical devices and components with high accuracy and reliability. This technology ensures that even the smallest parts fit perfectly and function flawlessly in lifesaving equipment.

Applications include:

– Surgical Instruments: Creation of highly precise tools for various surgical procedures.

– Prosthetics: Custom-made prosthetic limbs tailored to individual patient needs.

– Orthopedic Implants: Fabrication of hip, knee, and spinal implants with exacting specifications.

– Dental Devices: Production of implants, braces, and surgical guides.

– Microfluidic Devices: Development of tiny, precise channels for lab-on-a-chip applications.

– Diagnostic Equipment: Components for MRI machines, CT scanners, and more.

– Wearable Medical Devices: Manufacture of sensors and monitors for continuous patient care.

– Neurostimulators: Parts for devices that manage chronic pain and neurological disorders.

– Optical Instruments: High-precision lenses and components for various diagnostic tools.

– Robotic Surgery Systems: Components that enable precise movements and control in robotic-assisted surgeries.

– Hearing Aids: Miniaturized parts for improved auditory devices.

– Endoscopic Tools: Compact and precise instruments for minimally invasive surgeries.

– Pacemakers: Critical components for reliable cardiac rhythm management devices.

– Laboratory Automation: Parts for automated systems that handle high-throughput testing and analysis.

SourcifyChina’s precision medical machining involves state-of-the-art materials, ensuring high-quality and reliable medical components. They employ biocompatible metals such as titanium and stainless steel, offering excellent strength and resistance to corrosion.

These metals are favored for implants and surgical tools due to their durability and compatibility with human tissues. Titanium, in particular, is lightweight, reducing patient discomfort and enhancing the longevity of medical devices used within the body.

In addition to metals, SourcifyChina utilizes high-performance polymers like PEEK. PEEK is known for its superior mechanical properties and resistance to degradation, making it ideal for orthopedic and spinal implants.

For components requiring transparency or flexibility, SourcifyChina incorporates advanced ceramics and silicone rubber. Ceramics offer incredible toughness and wear resistance, while silicone is used in devices needing comfortable, flexible applications.

The combination of these specialized materials with precise machining techniques ensures that SourcifyChina delivers medical solutions that meet strict industry standards, enhancing patient safety and treatment outcomes.

SourcifyChina excels in precision medical machining, emphasizing stringent quality control processes to ensure the production of high-quality, reliable medical components. Their advanced manufacturing techniques comply with international standards.

The company’s quality control begins with thorough inspections of raw materials to ensure they meet strict specifications. These materials are then subjected to meticulous machining processes using state-of-the-art equipment.

Each stage of manufacturing undergoes rigorous testing and validation procedures. SourcifyChina employs cutting-edge measuring instruments and technologies to conduct real-time monitoring and ensure dimensional accuracy and consistency.

Moreover, SourcifyChina professionals are trained to follow stringent Standard Operating Procedures (SOPs) to mitigate any deviations or anomalies during the production process. Their vigilant approach minimizes defects.

Final product inspections include comprehensive testing for durability, functionality, and safety. SourcifyChina ensures all medical components pass these exacting standards before packaging and delivery.

Lastly, continuous improvement exercises are standard practice, integrating customer feedback and technological advancements. This relentless pursuit of perfection solidifies their reputation for producing superior medical machining solutions.

SourcifyChina Precision Medical Machining offers unparalleled capabilities in creating highly accurate and customized medical devices. Utilizing advanced CNC machining techniques, the company ensures every component meets stringent quality standards.

The company employs state-of-the-art equipment coupled with skilled technicians to produce intricate parts for medical instruments, implants, and surgical devices. This ensures a reliable and efficient production process.

SourcifyChina’s team specializes in working with biocompatible materials such as stainless steel, titanium, and specialized medical-grade plastics. This versatility caters to diverse medical applications and demands.

Comprehensive quality control is integral to SourcifyChina’s operations. They utilize rigorous testing and inspection procedures, ensuring all products adhere to regulatory requirements and customer specifications.

The company’s robust infrastructure also supports rapid prototyping, allowing for quick turnaround times on custom orders. This adaptability is crucial in the fast-paced medical field.

Customer satisfaction is a core value at SourcifyChina. The company strives to exceed expectations by delivering precision-machined components that perform reliably in critical medical applications.

With a commitment to innovation and excellence, SourcifyChina continually invests in new technologies and training. This ensures they stay ahead in the competitive medical machining landscape.

In conclusion, SourcifyChina’s precision medical machining capabilities offer reliability, versatility, and exceptional quality. Their dedication to technical excellence and customer satisfaction solidifies their position as a trusted partner in the medical device industry.

Precision medical machining offers numerous advantages in the healthcare industry, fundamentally improving the quality and efficacy of medical devices and implants.

– High Accuracy and Precision: Enables the production of intricate and complex components with minimal tolerances.

– Customization: Facilitates personalized medical solutions tailored to individual patient needs, enhancing treatment outcomes.

– Enhanced Biocompatibility: Advanced materials and techniques ensure biocompatibility, minimizing the risk of rejection or complications.

– Improved Durability: Components manufactured through precision machining tend to have superior strength and longevity.

– Cost-Effectiveness: Reduces waste and improves efficiency, leading to cost savings in the long term.

– Rapid Prototyping: Accelerates the development of new medical devices, bringing innovations to market faster.

– Consistency in Mass Production: Maintains consistent quality across large volumes, crucial for widely-used medical devices.

– Reduced Risk of Human Error: Automation and computer-controlled processes lower the chance of manual errors.

– Better Patient Outcomes: Leads to improved surgical precision and overall better health outcomes for patients.

– Regulatory Compliance: Meets strict medical standards and regulatory requirements, ensuring safety and efficacy.

– Versatility: Adaptable across various medical fields, from orthopedics to cardiovascular applications.

These benefits collectively enhance the capabilities of modern medicine, offering improved solutions that are both efficient and effective.

Precision medical machining is a specialized field that ensures the production of high-quality, intricately designed medical devices and components with unparalleled accuracy. Its features include:

– High Precision and Accuracy: Essential for producing complex medical components like implants and surgical instruments.

– Material Versatility: Capable of machining diverse materials such as titanium, stainless steel, plastics, and biomedical-grade composites.

– Advanced Technologies: Utilizes CNC machining, laser cutting, and 3D printing to achieve precise tolerances.

– Surface Finish Quality: Delivers superior surface finishes to meet stringent industry standards and functional requirements.

– Miniaturization Capability: Expertise in creating ultra-small parts for minimally invasive surgical tools and microimplants.

– Regulatory Compliance: Adheres to strict medical industry regulations like ISO 13485 and FDA standards.

– Customization: Allows for the fabrication of patient-specific implants and devices.

– Rapid Prototyping: Enables quick turnaround on prototypes for testing and validation.

– Robust Quality Control: Employs rigorous inspection processes and certification to ensure reliability and performance.

– Cost Efficiency: Optimized for mass production while maintaining high standards.

These features underscore the critical role of precision medical machining in advancing medical technology and patient care.

SourcifyChina is a leading provider of precision medical machining, specializing in custom products and projects tailored to the unique needs of the healthcare industry. Their cutting-edge technology ensures products meet stringent medical standards.

They utilize innovative CNC machining processes to create a variety of medical components, from surgical instruments to diagnostic equipment. Each product undergoes rigorous quality checks to ensure precision and reliability.

SourcifyChina collaborates closely with clients to understand their specific requirements, allowing for the creation of bespoke medical solutions. This client-centric approach enhances efficiency and fosters long-term partnerships.

Their team of skilled engineers and machinists is dedicated to continuous improvement, leveraging advanced software and machinery. This commitment ensures that they stay at the forefront of the medical machining industry.

Additionally, SourcifyChina adheres to strict regulatory standards, ensuring all products are safe and effective. Their comprehensive services range from prototype development to full-scale production runs.

By focusing on precision, quality, and customer satisfaction, SourcifyChina has established itself as a trusted partner in the medical field. Their expertise in custom medical machining solves complex manufacturing challenges.

For healthcare providers seeking reliable and precise medical components, SourcifyChina offers a seamless and efficient manufacturing solution. Their dedication to excellence ensures that every product meets the highest industry standards.

SourcifyChina Precision Medical Machining is a leading provider in the realm of precision engineering dedicated to the medical sector. With its roots firmly planted in China’s burgeoning industrial landscape, the company has rapidly risen to prominence by offering unmatched medical machining solutions characterized by exceptional accuracy and reliability. Specializing in the production of intricate medical devices and components, SourcifyChina employs cutting-edge CNC machining technologies alongside a rigorous quality control system to meet the stringent standards of the healthcare industry. Their expertise spans various critical applications, including surgical instruments, orthopedic implants, and diagnostic equipment. The company’s commitment to innovation and precision is reflected in its continuous investment in advanced machinery and skilled engineering talent. By adhering to global standards such as ISO 13485, SourcifyChina ensures that their products not only meet but exceed client expectations. This dedication has positioned them as a trusted partner for medical professionals and OEMs worldwide, emphasizing their role in enhancing patient care through superior medical components.

Precision medical machining, typically associated with producing intricate components for healthcare devices, has found significant applications in the aerospace, defense, and marine sectors. In aerospace, the demand for lightweight, high-strength parts necessitates the use of precise machining techniques originally developed for the medical field. These sophisticated methods enable the creation of components with tight tolerances and complex geometries essential for high-performance aircraft. For instance, precision machining is crucial for manufacturing turbine blades, fuel injector nozzles, and control systems, ensuring reliable operation under extreme conditions. The rigorous quality standards and meticulous processes borrowed from medical machining significantly enhance the durability and efficiency of aerospace systems.

Similarly, in the defense sector, precision medical machining contributes to the development of tactical equipment and weaponry that demand exceptional accuracy and reliability. Components such as targeting system parts, sensor housings, and missile guidance mechanisms benefit from the advanced precision machining techniques designed to achieve microscopic tolerances. This precision ensures the functionality and safety of critical defense apparatus. In the marine industry, the ability to produce corrosion-resistant and high-durability parts using materials processed through precision medical machining becomes invaluable. Engine components, navigation systems, and pressure vessels crafted with such precision offer enhanced performance and longevity, crucial for sustained operations in harsh marine environments. Thus, the transfer of precision medical machining technologies to these high-stakes industries not only enhances performance and safety but also drives innovation and operational excellence.

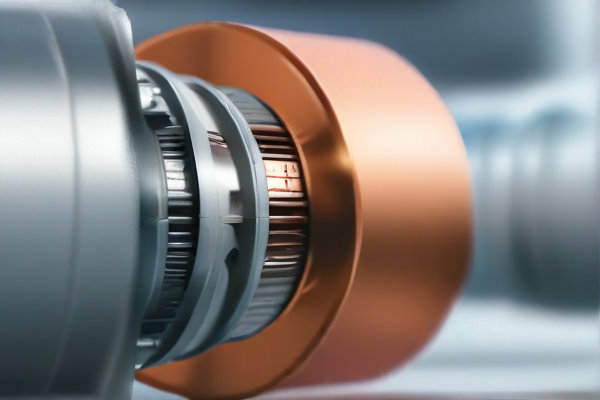

Precision medical machining, traditionally a pillar in creating intricate medical implants and instruments, is increasingly finding applications in the automotive and electronics industries. In the automotive realm, this advanced machining technology is pivotal in manufacturing highly precise components such as fuel injectors, sensor housings, and various engine parts. The stringent tolerances and detailed specifications required for these parts demand the same level of precision found in medical machining. By leveraging this technology, the automotive industry can achieve higher performance, efficiency, and reliability in their vehicles. Additionally, advancements in electric vehicles (EVs) also benefit from precision machining, where the critical alignment and calibration of electric motors and battery casings are essential for optimal vehicle performance and safety.

The electronics industry similarly reaps substantial benefits from precision medical machining practices. In the production of devices such as smartphones, laptops, and intricate circuit boards, the need for miniaturized and highly accurate components is paramount. Precision machining ensures that components fit together flawlessly, enhancing the performance and longevity of electronic devices. This technology also plays a crucial role in the development of semiconductor equipment, where minuscule yet crucial parts dictate the overall functionality and efficiency of electronic components. In essence, transferring the meticulous standards and capabilities of medical machining to electronics allows for innovation and the creation of more powerful, reliable, and compact devices. The cross-industry application exemplifies the versatility and far-reaching impact of precision medical machining beyond its traditional confines.

Precision medical machining, renowned for its meticulous accuracy in developing medical devices, plays a substantial role in the construction industry as well. The same principles and techniques that produce minute tolerances in medical instruments are applied to create durable, precision-engineered components for construction machinery and tools. These precision parts enhance the performance and longevity of construction equipment, leading to greater efficiency and safety on job sites. For instance, precision-machined hydraulic components are essential for the reliable operation of heavy machinery, which must endure harsh conditions and rigorous use. This crossover of technology ensures that construction projects can be executed with superlative precision, reducing errors, and structural inconsistencies, ultimately leading to safer and more robust buildings.

In the energy sector, precision medical machining is instrumental in the fabrication of components for renewable energy systems, such as wind turbines and solar panels. High-precision machining allows for the production of intricate parts that are crucial for the optimal functioning of these technologies. For wind turbines, components such as gearboxes and rotor hubs require precise engineering to ensure maximum efficiency and durability under constant mechanical stress. Similarly, in solar energy systems, precision-machined mounts and tracking components help in accurate positioning and alignment of solar panels, thereby enhancing their efficiency in capturing sunlight. By borrowing techniques from the medical field, the energy sector benefits from enhanced durability, reduced downtime, and increased efficiency in energy production, contributing significantly to the advancement of sustainable energy solutions.

The Industrial Equipment industry sees significant advancements through the application of precision medical machining. High precision and reliability are critical aspects shared by both medical devices and industrial tools, making precision machining techniques highly relevant in the manufacturing of components like sensors, intricate machine parts, and high-performance bearings. Utilizing precision medical machining processes ensures that these components achieve the exacting tolerances and longevity required for industrial applications. Techniques such as CNC machining and laser cutting, borrowed from medical device fabrication, deliver superior accuracy and consistency, allowing industrial equipment to operate more efficiently and reliably under extreme conditions.

Moreover, the focus on miniaturization in the medical field translates well into the realm of industrial equipment, where compact yet powerful components are increasingly in demand. Precision medical machining allows for the creation of smaller, more efficient parts without sacrificing performance or durability. This miniaturization enables the development of sophisticated machinery that is lighter, faster, and more cost-effective to produce and maintain. Additionally, the emphasis on biocompatibility and sterility in medical machining translates into enhanced material performance and reduced contamination risks in sensitive industrial processes. Thus, the convergence of precision medical machining with the industrial equipment sector not only drives technological innovation but also enhances the operational capabilities and reliability of modern industrial machinery.

Precision medical machining is integral to the development and manufacturing of advanced medical devices, ensuring these tools meet the stringent quality and safety standards essential for healthcare applications. This specialized machining technology allows for the production of intricate components with extremely tight tolerances, critical for devices such as surgical instruments, implants, and diagnostic equipment. The ability to machine materials such as titanium, stainless steel, and high-performance polymers with exacting precision enhances the reliability and effectiveness of these devices. Techniques like CNC machining, laser cutting, and micro-machining are employed to produce components with exceptional detail and consistency, enabling innovations in minimally invasive surgical tools and custom-fitted implants, which directly contribute to improved patient outcomes and procedural advancements.

One of the most significant applications of precision medical machining is in the production of orthopedic and cardiovascular implants. These implants often require complex geometries and biocompatible materials to integrate seamlessly with the human body while maintaining structural integrity and functionality. Precision machining ensures that these implants meet the required specifications and surface finishes, which are crucial to their success and longevity. Furthermore, precision medical machining supports the growing trend towards personalized medicine by enabling the manufacture of custom devices tailored to individual patient anatomy. This level of customization not only enhances the performance of medical devices but also reduces the risk of complications and improves recovery times, ultimately advancing the overall quality of healthcare delivery.

Precision medical machining plays a crucial role in the manufacturing of complex, high-precision components used in the medical field. This application involves the use of advanced CNC (Computer Numerical Control) machines, lathes, milling machines, and other sophisticated technology to create components with tight tolerances and intricate geometries. From surgical instruments and orthopedic implants to diagnostic equipment and dental devices, precision medical machining ensures that these components meet stringent regulatory standards and perform reliably in critical medical procedures. The ability to work with a wide range of materials, including stainless steel, titanium, and various medical-grade plastics, further enhances the versatility and efficacy of precision medical machining in the healthcare sector.

In the manufacturing realm, precision medical machining is indispensable for producing high-quality, highly functional medical devices. The process allows for the rapid prototyping and mass production of parts that are not only precise but also biocompatible and durable. The use of CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems enables manufacturers to design and simulate components before they reach production, minimizing errors and reducing time-to-market. Additionally, the ongoing advancements in precision machining technologies—such as multi-axis machining and additive manufacturing—have pushed the boundaries of what is possible, enabling the creation of increasingly complex and specialized medical devices. These technological advancements ensure that medical professionals have access to the most effective tools and devices, ultimately improving patient outcomes and advancing medical science.

Sure, here are some FAQs along with their answers for “precision medical machining quality work from SourcifyChina factory”:

Q1: What is precision medical machining?

A1: Precision medical machining involves manufacturing high-quality medical components with exact specifications and tight tolerances. This process is essential for producing medical devices and instruments that ensure patient safety and effectiveness.

Q2: Why should I choose SourcifyChina factory for precision medical machining?

A2: SourcifyChina factory is known for its advanced machining technology, rigorous quality control processes, and experienced workforce. We adhere to international standards, ensuring all components meet or exceed industry requirements.

Q3: What materials can SourcifyChina factory work with?

A3: SourcifyChina factory can machine a wide range of materials such as stainless steel, titanium, aluminum, and various medical-grade plastics. Our experts help choose the appropriate material for your specific applications.

Q4: How does SourcifyChina ensure quality in precision medical machining?

A4: Quality assurance is a multi-step process at SourcifyChina. We utilize state-of-the-art inspection tools, conduct systematic testing, and follow strict procedures to ensure each part meets the required specifications and tolerances.

Q5: What certification does SourcifyChina have for medical machining?

A5: SourcifyChina holds several international certifications like ISO 13485, which is specific to medical devices. These certifications validate our commitment to quality and compliance with industry regulations.

Q6: Can SourcifyChina handle custom designs?

A6: Yes, SourcifyChina specializes in custom designs. Our engineering team collaborates closely with clients to transform unique requirements into high-quality, precision-machined components.

Q7: What is the typical lead time for a project?

A7: Lead times vary based on project complexity and volume. Generally, we provide a detailed timeline after understanding your specific needs and project scope.

Q8: Does SourcifyChina offer after-sales support?

A8: Absolutely. We offer comprehensive after-sales support, including troubleshooting, repairs, and replacement of defective parts to ensure complete client satisfaction.

Q9: How do I get a quote for my project?

A9: You can request a quote by contacting us through our website or via email. Provide as much detail as possible about your project, and our team will get back to you with a tailored quotation.

Q10: What industries does SourcifyChina serve?

When considering precision medical machining manufacturing from SourcifyChina factory, there are several critical tips to ensure a successful partnership and high-quality products:

1. Verify Certifications: Ensure the factory holds relevant certifications such as ISO 13485 for medical devices. This guarantees adherence to rigorous quality management systems.

2. Check Material Compliance: Confirm that all materials used meet international standards for medical devices. This includes biocompatibility and sterilization compatibility for patient safety.

3. Assess Capabilities: Review the factory’s machining capabilities, including CNC machining, EDM, and laser cutting. Advanced technologies like 5-axis CNC machines are crucial for complex medical components.

4. Quality Control: Evaluate the factory’s quality control processes. This should include in-process inspections, final inspections, and detailed reporting. Ask about their use of precision measurement tools like CMM (Coordinate Measuring Machines) and optical inspection systems.

5. Prototyping: Utilize their prototyping services to test and validate designs before full-scale production. Rapid prototyping can help identify and correct design flaws early.

6. Supply Chain Management: Ensure they have a robust supply chain for critical materials and components. This helps maintain production schedules and avoid delays.

7. Communication: Foster clear and continuous communication. Language can be a barrier, so having a bilingual project manager can mitigate misunderstandings.

8. Intellectual Property Protection: Discuss IP protection measures with the factory to safeguard your designs and innovations.

9. Compliance with Regulatory Standards: Ensure the factory is compliant with regulatory standards specific to your target market, such as FDA regulations in the USA or CE markings in Europe.

10. Visit the Facility: If possible, visit the factory to assess their operations, cleanliness, and workflow first-hand. This provides deeper insight into their capabilities and operational standards.

By focusing on these aspects, you can enhance the likelihood of successful collaborations and high-quality precision medical components relevant to stringent healthcare standards.

What is the minimum order quantity (MOQ) for precision medical machining?

Our MOQ varies depending on the complexity and specifics of the project. Typically, the MOQ ranges from 50 to 100 units. However, we are open to discussing smaller orders for prototyping purposes.

What materials can SourcifyChina work with in precision medical machining?

We can work with a wide variety of materials including, but not limited to, stainless steel, titanium, aluminum, and various medical-grade plastics. If you have specific material requirements, please let us know so we can accommodate your needs.

What quality standards does SourcifyChina adhere to?

We strictly adhere to international quality standards, including ISO 9001 and ISO 13485 certifications. Our quality control processes ensure that all products meet the rigorous demands of the medical industry.

How long is the typical lead time for an order?

Lead times vary depending on the complexity and quantity of the order. Generally, our lead times range from 4 to 8 weeks. We aim to provide accurate delivery timelines after evaluating the specifics of each project.

Can you do custom designs and prototypes?

Yes, we offer custom design and prototyping services. Our engineering team can work with your specifications to create prototypes for validation before moving into full-scale production.

What types of finishing services do you offer?

We offer a variety of finishing services to meet your needs, including polishing, anodizing, passivation, and more. Each finishing option can enhance the durability and appearance of your medical components.

Do you offer regulatory compliance support for medical devices?

Yes, our team is experienced in navigating the regulatory requirements for medical devices. We can assist with documentation and compliance to ensure your products meet all necessary regulations.

How do I get a quote for my project?

To get a quote, please provide us with detailed information about your project, including CAD files, material specifications, and quantities required. You can send this information via email or through our website’s contact form.

Sourcing precision medical machining from a SourcifyChina factory requires careful planning to ensure quality and compliance with industry standards. Here are some key tips:

1. Research and Verify: Start by researching SourcifyChina and its network to find factories specializing in medical machining. Ensure they have relevant certifications such as ISO 13485, which is crucial for medical device manufacturing.

2. Specify Requirements: Clearly communicate your precision requirements, including tolerances, materials, and surface finishes. Provide detailed drawings and specifications to avoid misunderstandings.

3. Check Quality Management Systems (QMS): Verify that the factory has a robust QMS in place, ensuring consistent quality and traceability. Look for evidence of previous successful projects in the medical field.

4. Request Samples: Ask for samples to evaluate the factory’s capability to meet your specifications. Inspect these for precision, material integrity, and compliance with your standards.

5. Audit the Factory: If possible, conduct an in-person audit or hire a third-party inspection service. This helps verify their equipment, facilities, and adherence to quality protocols.

6. Assess Communication Skills: Effective communication is critical. Ensure the factory’s representatives are responsive and can understand and address technical queries promptly.

7. Review Logistics: Consider logistics and lead times. Discuss shipping arrangements, potential tariffs, and any risks associated with sourcing from China.

8. Check Compliance: Ensure the factory complies with global and your specific country’s medical device regulations and standards. Non-compliance can lead to significant legal and financial issues.

9. Establish Contracts: Secure detailed contracts outlining expectations, timelines, quality controls, and contingencies for non-compliance.

10. Maintain Regular Oversight: Continuously monitor production processes and quality through regular updates and quality checks to ensure ongoing compliance and precision.

By following these steps, you can effectively source precision medical machining from a SourcifyChina factory while minimizing risks and ensuring high-quality outcomes.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.