Technology and Applications of router bit cnc

Router bits for CNC (Computer Numerical Control) machines are essential tools in modern manufacturing and woodworking. They are cutting tools specifically designed for use in CNC routers, allowing for precise and efficient material removal. Here’s an overview of their technology and applications:

Technology

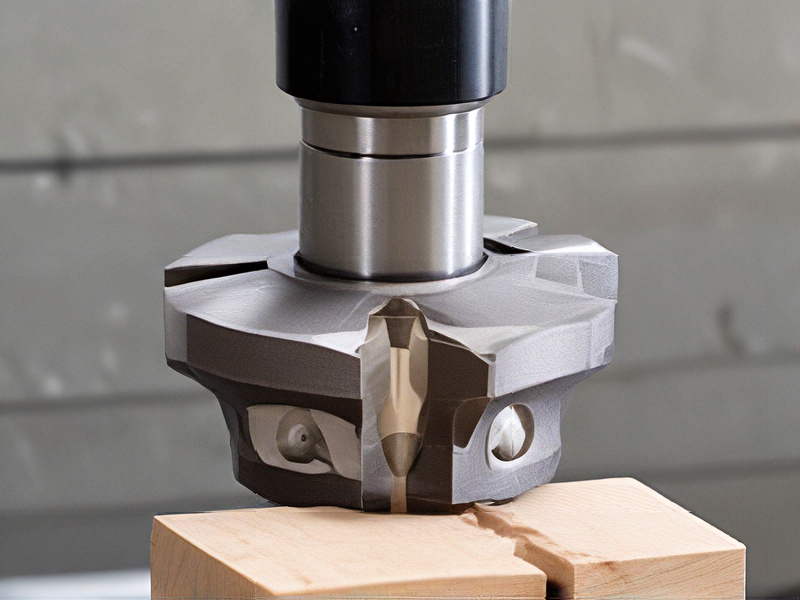

1. Design and Material: Router bits are made from high-speed steel (HSS), carbide, or diamond-tipped materials. Carbide-tipped bits are most common due to their durability and ability to maintain sharpness.

2. Types: They come in various shapes and sizes, including straight, spiral, V-groove, and flush trim bits. Each type serves a specific purpose, such as cutting, carving, engraving, or trimming.

3. Shank Size: The shank size of router bits typically ranges from 1/4 inch to 1/2 inch, affecting their compatibility with different CNC machines and their stability during operations.

4. Coatings: Some router bits have coatings like titanium nitride (TiN) to reduce friction, increase hardness, and extend the tool’s life.

Applications

1. Woodworking: Router bits are extensively used in woodworking for tasks like shaping edges, creating intricate designs, cutting joints, and hollowing out sections of wood.

2. Sign Making: CNC router bits can engrave and carve out detailed signs from materials like wood, acrylic, and metal.

3. Cabinetry and Furniture: They are vital in the creation of custom cabinetry, furniture pieces, and decorative trim work, ensuring precision and repeatability.

4. Prototyping: In manufacturing, router bits are used for prototyping and producing parts from materials such as plastics, foams, and composites.

5. Art and Craft: Artists use CNC router bits to craft detailed patterns and sculptures from various materials.

Advantages

– Precision: CNC router bits enable high precision and accuracy, crucial for intricate designs and detailed work.

– Efficiency: They allow for faster production times compared to manual methods.

– Versatility: Suitable for a wide range of materials including wood, plastics, aluminum, and other non-ferrous metals.

In conclusion, CNC router bits are integral to numerous industries, offering precision, efficiency, and versatility in cutting and shaping materials. Their advanced technology and diverse applications make them indispensable in modern manufacturing and artisanal craftsmanship.

Quality Testing Methods for router bit cnc and how to control quality

Quality testing methods for CNC router bits typically involve several key approaches to ensure they meet performance standards:

1. Dimensional Accuracy: Use calipers or micrometers to measure critical dimensions such as diameter, flute length, and overall length. Deviations from specifications can affect performance.

2. Material Composition: Perform chemical analysis or use spectroscopy techniques to verify the composition of materials used (e.g., carbide tips). This ensures they meet strength and durability requirements.

3. Hardness Testing: Utilize a Rockwell or Vickers hardness tester to ensure the router bit’s hardness is within specified ranges. Hardness affects wear resistance and cutting ability.

4. Surface Finish Inspection: Use profilometers or visual inspection to assess the surface finish of cutting edges and flutes. Smooth surfaces reduce friction and improve cutting performance.

5. Run-Out Testing: Mount the router bit in a holder and measure run-out using dial indicators or laser measurement tools. Excessive run-out can lead to vibration and poor cut quality.

6. Cutting Performance Evaluation: Conduct test cuts on appropriate materials at recommended speeds and feeds. Evaluate parameters such as chip formation, edge quality, and tool life.

To control quality effectively:

– Establish Specifications: Define clear quality standards for dimensions, materials, hardness, and surface finish.

– Supplier Quality Assurance: Implement regular audits and performance reviews with suppliers to ensure they adhere to agreed-upon standards.

– In-Process Inspection: Incorporate checkpoints during manufacturing to catch deviations early.

– Document Control: Maintain comprehensive records of testing results and inspections to trace issues and improvements over time.

By employing these methods and controls, manufacturers can ensure CNC router bits meet the required standards for performance and reliability.

Tips for Procurement and Considerations when Purchasing from router bit cnc

When procuring router bits for CNC machines, consider the following tips and key considerations to ensure you make informed and cost-effective decisions:

1. Quality and Material: Ensure the bits are made from high-quality materials like carbide or high-speed steel. Carbide-tipped bits offer durability and better performance for harder materials.

2. Bit Type: Choose the appropriate bit type for your specific application. Common types include straight, spiral, V-groove, and round-over bits. Each type serves different functions, such as cutting, carving, or engraving.

3. Manufacturer Reputation: Purchase from reputable manufacturers known for consistent quality and reliability. Check reviews and seek recommendations from industry peers.

4. Shank Size: Verify the shank size compatibility with your CNC router. Common sizes are 1/4 inch and 1/2 inch. Using the correct shank size ensures stability and reduces the risk of bit breakage.

5. Coating: Look for bits with coatings like titanium or diamond. These coatings reduce friction, enhance cutting performance, and prolong the bit’s lifespan.

6. Cost vs. Value: While cost is a significant factor, prioritize value over the lowest price. High-quality bits may have a higher upfront cost but offer better longevity and performance, reducing overall expenses in the long run.

7. Vendor Support: Choose suppliers that provide excellent customer support, including technical assistance and return policies. Good support can help resolve issues quickly and keep your operations running smoothly.

8. Inventory Management: Maintain an inventory of essential bits to avoid downtime. Regularly review usage patterns and restock as necessary to ensure a consistent supply.

9. Trial and Testing: If possible, conduct trials with new bits on less critical projects to assess their performance before fully integrating them into your production process.

10. Proper Storage and Handling: Store bits properly to prevent damage. Use dedicated holders or cases to protect the cutting edges and shanks from nicks and wear.

By considering these factors, you can optimize your CNC operations, enhance product quality, and achieve greater efficiency in your production processes.

FAQs on Sourcing and Manufacturing from router bit cnc in China

Certainly! Here are some FAQs regarding sourcing and manufacturing router bits CNC in China:

1. Why source router bits CNC from China?

China offers competitive pricing due to lower manufacturing costs and a robust industrial infrastructure.

2. How can I find reliable manufacturers in China?

Utilize online platforms like Alibaba, attend trade shows such as Canton Fair, and conduct thorough background checks and due diligence.

3. What are the typical lead times for manufacturing?

Lead times vary but are generally between 4-8 weeks depending on order volume and complexity.

4. What about quality control and assurance?

Ensure suppliers have certifications like ISO 9001 and conduct regular quality inspections throughout production.

5. Are there language and communication challenges?

Yes, language barriers can exist. Clear communication and possibly hiring a local agent or translator can mitigate issues.

6. How do I handle shipping and logistics?

Discuss shipping terms (FOB, CIF, etc.) with suppliers and consider using freight forwarders for efficient logistics.

7. What are the payment terms usually accepted?

Common payment terms include T/T (Telegraphic Transfer) and L/C (Letter of Credit), but negotiate based on your comfort and trust level.

8. How can I protect intellectual property (IP) when sourcing from China?

Sign enforceable contracts, register trademarks, and consider consulting legal experts for additional protection measures.

9. What should I consider when selecting materials for router bits?

Choose materials based on durability, precision requirements, and compatibility with intended applications.

10. What after-sales support can I expect?

Clarify warranty terms and ensure suppliers offer technical support and replacement options if needed.

Navigating sourcing and manufacturing in China for CNC router bits requires careful planning, communication, and adherence to quality standards to ensure a successful partnership and product outcome.