Choosing SourcifyChina Factory for sand casting services offers unmatched expertise and advanced technology in metal casting. With years of experience, they ensure high-quality, precise castings tailored to meet your specific needs. Their skilled team guarantees excellent craftsmanship, resulting in durable and reliable products.

SourcifyChina maintains a strict quality control system to adhere to international standards. This ensures every product not only meets but exceeds client expectations. The factory’s rigorous testing processes and certified materials underscore their commitment to excellence, making them a trustworthy partner in sand casting services.

Competitively priced, SourcifyChina provides a cost-effective solution without compromising quality. Their streamlined production processes and efficient resource management allow them to offer reasonable rates, ensuring that buyers get the best value for their money. Clients appreciate the balance between affordability and high standards.

Furthermore, SourcifyChina prides itself on exceptional customer service. They prioritize clear communication, timely delivery, and customer satisfaction. By maintaining open lines of dialogue throughout the procurement process, they ensure that buyers are always informed and satisfied with the progress and final result.

Lastly, the factory’s sustainability practices highlight its commitment to environmental responsibility. By using eco-friendly materials and energy-efficient processes, SourcifyChina not only delivers superior products but also contributes to minimizing their carbon footprint. This dedication to green practices makes them an excellent choice for conscientious buyers.

In summary, SourcifyChina Factory excels in providing high-quality sand casting services by combining expertise, rigorous quality control, competitive pricing, excellent customer service, and sustainable practices. This comprehensive approach ensures that customers receive top-notch castings that meet their needs and standards, establishing SourcifyChina as a leading choice for buyers.

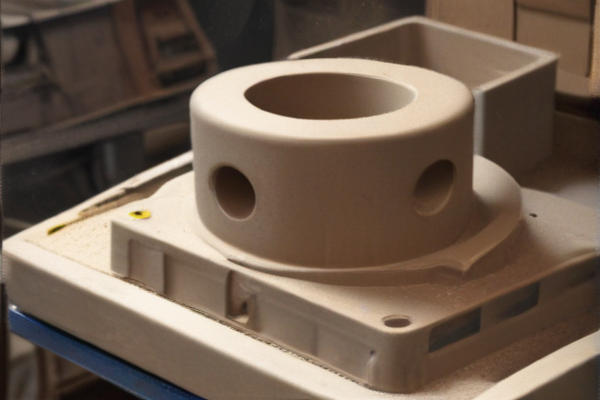

Sand casting is a versatile method for creating metal parts by crafting a mold from a sand mixture. This process is ideal for producing complex shapes and large components. Here are various types and options for sand casting services:

– Green Sand Casting: Utilizes wet sand for molding, offering cost-effective and quick production.

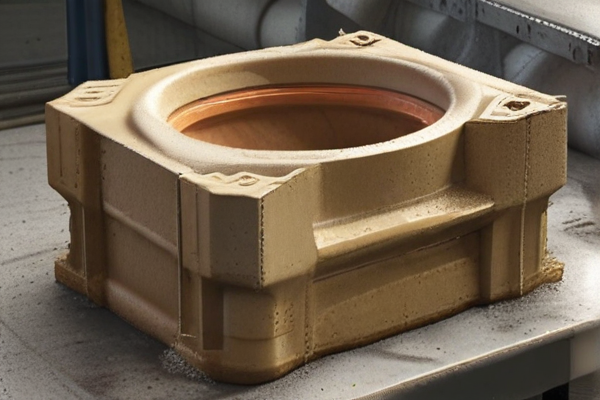

– Resin Sand Casting: Employs resin-bonded sand, providing better surface finish and higher strength.

– Dry Sand Molding: Involves drying the sand mold, enhancing mold rigidity and dimensional accuracy.

– No-Bake Sand Casting: Uses a chemical binder to harden the mold without baking, perfect for larger parts.

– CO2 Sand Casting: Utilizes CO2 gas for hardening the mold, improving mold hardness and reducing defects.

Additional

Options:

– Prototyping Services: Offers rapid prototyping for testing designs before full-scale production.

– Tooling and Pattern Making: Custom tooling and pattern creation for precise part reproduction.

– Core Making: Essential for forming intricate internal geometries in cast parts.

– Machine Finishing: Post-casting machining services to achieve tight tolerances and superior finishes.

– Quality Control: Rigorous inspections, including X-ray, ultrasound, and dimensional checks to ensure product integrity.

– Material Selection: Variety of metals including aluminum, iron, steel, and bronzes to meet specific project requirements.

– Design Assistance: Expert guidance on optimizing designs for the sand casting process to improve performance and reduce costs.

– Batch Production: Capabilities for both low-volume and high-volume production runs.

By exploring these various options, you can find a sand casting service that aligns perfectly with your project needs, ensuring quality and efficiency.

Sand casting services are widely used in manufacturing due to their versatility, cost-effectiveness, and ability to produce complex geometries. This method is suitable for various industries and applications.

– Automotive parts: engine blocks, manifolds, and transmission housings.

– Aerospace components: turbine blades and structural parts.

– Industrial machinery: pumps, valves, and gearboxes.

– Marine equipment: propellers and hull components.

– Construction: architectural elements and structural supports.

– Agriculture: machinery parts and implements.

– Energy sector: wind turbine components and solar panel frames.

– Art and sculpture: custom metal artworks.

– Prototyping: creating functional prototypes for testing and development.

– Custom manufacturing: specialized parts for niche applications.

SourcifyChina’s sand casting services utilize high-quality materials to produce durable and precise metal components. The materials range from various grades of iron, steel, and aluminum to specialized alloys designed to meet specific industrial requirements.

The use of silica sand in the casting process ensures smooth finishes and detailed reproduction of the designed parts. This high-quality sand can withstand extreme temperatures, providing consistent performance and high reliability in produced components.

Additionally, SourcifyChina employs advanced bonding agents and additives to improve the sand’s cohesion and strength. These enhancements result in reduced defects, minimized waste, and higher efficiency in the casting process.

The company’s careful selection of materials ensures that each cast component meets stringent quality standards. This attention to detail supports various industries, including automotive, aerospace, and machinery, ensuring their parts are reliable and long-lasting.

Overall, SourcifyChina’s dedication to using premium materials in their sand casting services leads to superior product performance and customer satisfaction. Their commitment to quality and innovation positions them as a leader in the sand casting industry.

SourcifyChina emphasizes stringent quality control measures in its sand casting services to ensure high standards in manufacturing. This involves a rigorous initial examination of raw materials, guaranteeing their composition and quality meet industry specifications.

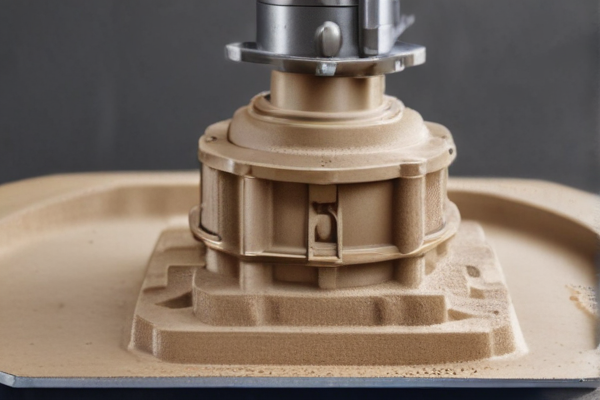

The company’s production process incorporates advanced techniques, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), to optimize precision and efficiency. Continuous monitoring throughout the casting process helps in detecting any deviations or defects early on.

SourcifyChina employs specialized tools for non-destructive testing (NDT) methods, such as X-ray inspection and ultrasonic testing, to evaluate the internal structure of the cast products. These tests ensure that each item meets strict performance and safety criteria.

Post-production, the cast products undergo thorough dimensional inspections using coordinate measuring machines (CMM). This step verifies that the products conform to the exact specifications outlined by the client, ensuring a high level of accuracy and consistency.

Finished products are subjected to a final inspection phase, where they are tested for mechanical properties, including tensile strength, hardness, and impact resistance. This comprehensive approach underscores SourcifyChina’s commitment to delivering reliable, high-quality castings.

Customer feedback is integral to SourcifyChina’s quality control process. The company regularly solicits input from clients to identify areas for improvement. This continuous feedback loop helps to refine their processes and maintain high standards.

In summary, SourcifyChina’s quality control in sand casting services involves the diligent inspection of raw materials, precise execution, non-destructive testing, dimensional accuracy checks, and mechanical property evaluations. This holistic approach ensures their products consistently meet and exceed client expectations.

SourcifyChina excels in providing high-quality sand casting services for a range of industries. Their expertise ensures precision crafting of components, meeting specific client requirements with technological advancements and rigorous quality control.

The company utilizes various types of sand molds, including green sand and resin-bonded molds, to produce intricate patterns. This versatility allows them to cater to various material specifications and complex geometrical shapes.

With state-of-the-art facilities, SourcifyChina guarantees efficient production processes. They employ advanced molding techniques and automated systems to increase production rates while maintaining stringent quality standards.

Their skilled workforce is trained in the latest methods, ensuring every casting meets the exact specifications. Detailed inspection protocols and continuous monitoring further guarantee product reliability and consistency.

SourcifyChina’s commitment to sustainability is evident through their eco-friendly practices. They implement waste reduction measures and recycle materials wherever possible, ensuring minimal environmental impact.

From aerospace to automotive industries, their sand casting services cater to a wide array of applications. They boast a diverse portfolio of satisfied clients, highlighting their reliability and expertise.

Overall, SourcifyChina’s sand casting services combine modern technology, skilled craftsmanship, and stringent quality control measures to deliver reliable, high-precision components for various industries, ensuring client satisfaction and environmental responsibility.

Sand casting is a versatile and cost-effective manufacturing process for metal parts, offering numerous benefits tailored to various industry needs.

– Versatility: Accommodates a wide range of metals and alloys, enabling the production of complex shapes and sizes.

– Cost-Effective: Generally less expensive than other casting methods, especially for small to medium production batches.

– Speed: Short lead times and relatively quick turnaround, making it ideal for prototype and low-volume production.

– Customization: Allows for highly detailed and custom designs, meeting specific and unique project requirements.

– Scalability: Suitable for both low-volume and high-volume production runs, ensuring flexibility for different market demands.

– Material Efficiency: High yield with minimal waste, contributing to sustainable manufacturing practices.

– Accessibility: Simplified process with readily available materials and tools, lowering the barrier for entry and facilitating wide adoption.

– Versatile Size Range: Capable of producing both very small and extremely large components, adding to its wide application range.

– Surface Finish: Offers good surface finish and dimensional accuracy when fine sand and advanced techniques are used.

– Repairability: The molds can be easily modified or repaired, ensuring longevity and lowering long-term costs.

– Minimal Post-Processing: Often requires little finishing, which speeds up overall production time.

– Thermal Properties: Handles metals at high temperatures well, essential for producing parts that withstand extreme conditions.

– Predictability: Well-understood process with predictable outcomes, aiding in efficient production planning.

In summary, sand casting services provide a blend of affordability, versatility, and efficiency, making them an excellent choice for a wide variety of manufacturing needs.

Sand casting services offer a cost-effective and versatile solution for producing metal parts of various sizes and shapes. Here’s a look at its key features:

– Wide Material Range: Compatible with numerous metals, including aluminum, bronze, brass, and iron.

– Cost-Effective: Lower tooling costs compared to other casting methods like die casting.

– Versatility: Suitable for low-volume production and complex, intricate designs.

– Customization: Easily customizable molds to match specific design requirements.

– Scalability: Efficiently handles both small and large runs.

– Rapid Prototyping: Quick turnaround for prototypes and adjustments.

– Durability: Produces robust parts capable of withstanding high temperatures and pressures.

– Reusability: Sand from molds can often be reclaimed and used multiple times, making it sustainable.

– Detail Precision: Can reproduce fine details accurately, essential for functional and aesthetic purposes.

– Flexibility in Size: The process can accommodate very large parts that other casting methods may not be able to handle.

– Minimal Waste: Sand casting generally results in minimal wastage, helping to conserve material and reduce costs.

– Heat Resistance: Sand molds can withstand extremely high temperatures, making them ideal for casting high-melting-point metals.

– Consistent Quality: Modern advancements in sand casting techniques ensure consistent quality and dimensional accuracy across runs.

In summary, sand casting services offer a blend of efficiency, adaptability, and cost-effectiveness, making it a preferred choice for many industrial applications.

SourcifyChina offers premier sand casting services, delivering high-quality custom products tailored to clients’ specifications. Their expertise covers a wide range of industries, ensuring precise manufacturing processes and superior results. Utilizing advanced technologies, they provide seamless integration from design to final production, guaranteeing efficiency and accuracy at every step.

The team at SourcifyChina is adept at managing complex projects, delivering both small and large batches with consistent quality. Their commitment to excellence ensures that each product meets stringent standards, supported by rigorous inspection processes. Clients can rely on their experienced engineers for innovative solutions and expert guidance throughout the project lifecycle.

SourcifyChina’s flexible approach accommodates various materials and intricacies, allowing for the creation of unique components and assemblies. Their customizable services include prototyping, tooling, and post-production treatments, all designed to meet specific client needs. This adaptability makes them a preferred partner for industries such as automotive, aerospace, and heavy machinery.

Furthermore, SourcifyChina emphasizes cost-effective solutions without compromising quality. By leveraging their expansive network and procurement capabilities, they offer competitive pricing and timely delivery. This balance of affordability and excellence positions them as a trusted provider of sand casting services in the market.

In conclusion, SourcifyChina’s sand casting services are distinguished by their innovation, reliability, and customer-centered approach. They excel in delivering custom products that meet diverse project requirements, backed by a team dedicated to achieving the highest standards of quality. Partnering with SourcifyChina ensures access to top-tier sand casting solutions, tailored to help clients achieve their operational and strategic goals effectively.

SourcifyChina is a premier provider of sand casting services, dedicated to delivering high-quality castings to a diverse range of industries. Leveraging years of expertise and cutting-edge technology, the company specializes in producing intricate and reliable metal castings tailored to meet precise specifications. With state-of-the-art facilities and a workforce of skilled professionals, SourcifyChina ensures each product undergoes rigorous quality control measures to uphold stringent international standards. The company’s commitment to excellence and customer satisfaction is evident in its thorough project management approach, from initial consultation to final delivery. Clients benefit from competitive pricing, timely delivery, and unparalleled technical support, making SourcifyChina a trusted partner in the global manufacturing landscape. Whether for automotive, aerospace, or industrial machinery applications, SourcifyChina’s sand casting services stand out for their precision, durability, and efficiency.

Sand casting services play a crucial role in the Aerospace industry by producing high-quality metal components used in aircraft and spacecraft. This method allows for the creation of complex geometries and intricate designs necessary for parts such as turbine blades, engine housings, and structural components. The capability of sand casting to use various metal alloys, including aluminum, titanium, and magnesium, ensures that the final products meet the stringent standards required for aerospace applications, such as high strength-to-weight ratio and resistance to extreme temperatures and pressure. Moreover, rapid prototyping and customizability of sand casting services accelerate the development process, enabling engineers to quickly iterate designs and make modifications, ultimately leading to more efficient and innovative aerospace technologies.

In the Defense and Marine sectors, sand casting services are equally vital. For defense applications, the ability to produce durable and reliable components is crucial for manufacturing military hardware such as armored vehicle parts, artillery shells, and structural components for naval vessels. The robustness of sand-cast parts ensures that they can withstand the harsh conditions and rigorous demands of military operations. Similarly, in the marine industry, components such as propellers, rudders, and engine parts benefit from the durability and versatility of sand casting. Marine environments impose challenges such as corrosion and wear, which can be effectively mitigated by selecting appropriate alloys during the sand casting process. The flexibility and efficiency of sand casting allow for the production of large, complex parts with reduced lead times and costs, making it an indispensable service for maintaining and advancing military and marine technologies.

Sand casting services have become integral to the automotive industry due to their cost-effectiveness and versatility. This traditional manufacturing method involves creating a mold from sand, which can then be used to form complex components from molten metal. For automotive applications, sand casting allows for the production of durable and intricate parts, such as engine blocks, transmission cases, and various structural components. Its flexibility in molding detailed features and the ability to work with a broad range of metals, including aluminum, iron, and steel, make it a preferred choice for both prototypes and large-scale production. Furthermore, advancements in sand casting have improved the precision and surface finish of the parts, meeting the high standards required for modern automotive manufacturing.

In the realm of electronics, sand casting is pivotal for producing robust and intricate enclosures and heat sinks for electronic devices. As electronic components continue to shrink in size while increasing in functionality, managing heat dissipation has become critical. Sand casting can create complex geometries for heat sinks that optimize thermal management, ensuring devices operate efficiently and safely. Additionally, the method is used to manufacture chassis and housings that protect sensitive electronic components from environmental factors and mechanical stresses. The ability to cast with materials like aluminum and magnesium, which offer excellent thermal conductivity and strength, further enhances the application of sand casting in electronics. This adaptability, combined with relatively low tooling costs, makes sand casting an attractive option for both high-volume production and custom electronic parts.

Sand casting services play a critical role in the construction industry, providing a cost-effective and versatile method for producing robust and durable metal components. This technique involves creating a mold out of sand, into which molten metal is poured to form structural elements such as beams, columns, and joint fixtures. One of the key benefits is its ability to produce large and complex shapes that are integral parts of buildings and infrastructure projects. For example, customized metal casings and supports used in bridges, high-rise buildings, and industrial facilities are often fabricated through sand casting. The relatively low cost and high adaptability of sand casting make it an ideal choice for construction projects requiring customized large-scale metal parts that need to withstand significant loads and environmental stressors.

In the energy sector, sand casting services are essential for manufacturing components used in various energy generation and distribution systems. Turbines, housings, and support structures for power plants, whether they are powered by fossil fuels, nuclear energy, or renewable sources like wind and hydro, frequently rely on parts made through sand casting. The method allows for precise engineering of components that must endure extreme pressures and temperatures, such as those found in boilers, heat exchangers, and other critical equipment. Additionally, sand casting is used to create wind turbine hubs and other large-scale parts necessary for renewable energy installations. The ability to produce these components reliably and efficiently supports the growing demand for sustainable energy solutions, highlighting the importance of sand casting in the pursuit of energy efficiency and technological advancement in the energy sector.

Sand casting services play a pivotal role in the Industrial Equipment industry, offering a versatile and cost-effective solution for producing large and complex metal components. This method involves creating a mold by packing sand around a pattern of the object to be cast. Once the mold is formed, molten metal is poured into the cavity, and after cooling, the sand is removed to reveal the finished part. Due to its flexibility, sand casting can be used for both ferrous and non-ferrous metals, making it suitable for manufacturing heavy-duty machinery parts, engine blocks, mining equipment, and components for the oil and gas sector. The process is especially beneficial for producing parts with intricate designs and geometries that would be challenging or expensive to create using other methods.

Moreover, sand casting services contribute to the Industrial Equipment industry’s efficiency and innovation by accommodating modifications and customizations with relative ease. Engineers and designers can quickly tweak and adapt patterns to refine the performance characteristics of the end product. This adaptability is crucial for developing prototype components and small-batch production runs, which are vital for testing and validation before full-scale production. Additionally, advancements in sand casting techniques and materials have led to improved surface finishes and enhanced dimensional accuracy, reducing the need for extensive post-casting machining operations. Consequently, sand casting remains a cornerstone of industrial manufacturing, blending traditional craftsmanship with modern technological advancements to meet the ever-evolving demands of the industry.

Sand casting services have found significant applications in the manufacture of medical devices, providing versatile solutions for producing complex components. This method involves creating a mold from a sand mixture into which molten metal is poured to form the desired part. Medical devices often require precision and durability, making sand casting particularly useful for producing intricate parts with complex geometries. Components such as surgical instruments, implantable devices, and diagnostic equipment benefit from the ability to create detailed internal structures and precise external shapes. Moreover, sand casting supports the use of various biocompatible metals, including stainless steel and titanium, ensuring that the final products meet stringent medical standards for safety and performance.

Furthermore, sand casting services offer considerable cost advantages and scalability for medical device manufacturers. The relatively low tooling cost and the ability to produce both small and large batches cater to both prototyping and high-volume production needs. This is especially valuable in the medical field, where the development process often requires multiple iterations and adaptations. Additionally, the flexibility of sand casting allows for the integration of custom features and modifications without significant expense, facilitating rapid development cycles and quicker time-to-market. Overall, sand casting services have proven to be an indispensable asset in the medical devices sector, enabling the creation of high-quality, reliable components that are critical to modern healthcare solutions.

Sand casting services play a pivotal role in both machining and manufacturing sectors, providing foundational components that are essential for various applications. In machining, sand casting allows for the creation of intricate and custom-designed metal parts that can later be refined with precision machining techniques. This method is particularly beneficial for producing complex geometries that would be cumbersome or expensive to manufacture using alternative methods. Sand casting results in components with excellent mechanical properties and the ability to handle high temperatures and stresses, making them ideal for critical applications in industries like automotive, aerospace, and heavy machinery.

Manufacturing applications of sand casting services also extend to mass production of metal parts, enabling producers to meet high demand with scalable solutions. The process involves creating a mold from sand and pouring molten metal into it to form the desired shape. This technique is adaptable for a broad range of metals, including aluminum, steel, and iron, thereby accommodating diverse manufacturing needs. Moreover, its cost-effectiveness and simplicity make it a preferred choice for producing large volumes of parts with consistent quality. As a result, sand casting is extensively employed in manufacturing various components such as engine blocks, pump housings, and valve bodies, underscoring its versatility and indispensability in the modern industrial landscape.

Sure! Here is a concise FAQ for manufacturing sand casting services quality work from SourcifyChina factory:

1. What is sand casting?

Sand casting is a versatile casting process where liquid metal is poured into a sand mould. The sand mould contains a cavity of the desired shape, and the molten metal solidifies within it to form the final cast product.

2. Why should I choose SourcifyChina for sand casting services?

SourcifyChina offers a combination of high-quality materials, state-of-the-art technology, and experienced professionals. We ensure precision, durability, and cost-effectiveness in every project.

3. What materials can be used in sand casting at SourcifyChina?

We can cast a wide range of metals, including aluminum, brass, bronze, cast iron, and steel. Our team can help you choose the right material for your specific application needs.

4. What is the typical lead time for sand casting projects?

The lead time varies depending on the complexity and size of the order. Typically, it ranges from 3 to 6 weeks from the time of order confirmation to delivery.

5. What quality control measures are in place at SourcifyChina?

We follow stringent quality control protocols including material inspection, dimensional checks, and non-destructive testing (NDT) to ensure the highest standards of quality.

6. Can you provide design and engineering support?

Yes, our engineering team can assist with design improvements, material selection, and optimizing manufacturing processes to enhance the quality and performance of your products.

7. How do I get a quote for sand casting services?

You can request a quote by providing your project specifications, including drawings, material requirements, and quantities. Our team will quickly assess and provide a detailed quotation.

8. What is your minimum order quantity (MOQ)?

We are flexible with order quantities and can accommodate both low-volume and high-volume production runs to meet customer needs.

9. How do you handle international shipping?

We offer comprehensive logistics support, including packing, customs clearance, and shipping to ensure your products arrive safely and on time.

10. Are there any post-casting services available at SourcifyChina?

Yes, we offer additional services like machining, heat treatment, surface finishing, and assembly according to your requirements.

Feel free to reach out for any more specific inquiries related to sand casting services at SourcifyChina.

When considering sand casting services from SourcifyChina factory, keep these key tips in mind to ensure a successful partnership:

1. Define Requirements Clearly: Before reaching out, have a comprehensive understanding of your project’s specifications, including dimensions, materials, and tolerances. Clear requirements help in accurate quotes and smoother production.

2. Evaluate Factory Capabilities: Ensure SourcifyChina has the technical capabilities and experience to handle your specific needs. Look for their portfolio, past projects, and any certifications that attest to their quality and capability.

3. Request Prototypes: If possible, ask for a prototype or sample to evaluate the quality of their sand casting. This helps in identifying potential issues early.

4. Quality Control: Inquire about their quality control processes. Reliable factories like SourcifyChina often have stringent QC measures to ensure the final product meets the required standards.

5. Communication: Establish clear channels of communication. Effective and prompt communication with the factory will help in addressing any concerns quickly.

6. Lead Time and Delivery: Confirm their lead times and how they manage shipping logistics. Timely delivery is crucial to maintaining your project schedule.

7. Cost Efficiency: While cost is a factor, ensure that the pricing reflects the value you’re receiving in terms of quality and service. Beware of prices that seem too good to be true.

8. Material Selection: Verify that they use high-quality materials suitable for your application. The choice of materials significantly affects the durability and performance of the final product.

9. Legal and Compliance: Ensure the factory complies with relevant industry standards and regulations. This includes environmental regulations and labor laws.

10. Cultural Understanding: Building a good rapport and understanding cultural nuances can enhance cooperation and reduce misunderstandings.

By following these tips, you can optimize the manufacturing partnership with SourcifyChina, ensuring high-quality sand casting services and successful project outcomes.

Sure, here are some frequently asked questions (FAQ) with answers about sourcing sand casting services from SourcifyChina factory:

Q: What is sand casting?

A: Sand casting is a metal casting process characterized by using sand as the mold material. It’s a versatile and economical method suitable for producing a wide range of metal components, from simple parts to complex shapes.

Q: Why should I choose SourcifyChina for sand casting services?

A: SourcifyChina offers high-quality sand casting services with advanced technology, experienced engineers, competitive pricing, and strict quality control. We ensure timely delivery and tailor our services to meet your specific requirements.

Q: What materials can be used in sand casting at SourcifyChina?

A: SourcifyChina can cast a variety of metals including aluminum, iron, steel, bronze, brass, and other specialized alloys based on your project needs.

Q: What industries does SourcifyChina serve?

A: SourcifyChina provides sand casting services to a wide range of industries, including automotive, aerospace, agricultural machinery, construction, and industrial equipment.

Q: How do I request a quote from SourcifyChina?

A: To request a quote, you can visit our website, fill out the online form with your project details, or contact us directly via email or phone. Please provide specifications, material requirements, and quantity for accurate quotes.

Q: What is the lead time for sand casting orders?

A: The lead time varies depending on the complexity, size, and quantity of the order. Typically, it ranges from a few weeks to a couple of months. We offer expedited services for urgent projects.

Q: Does SourcifyChina offer any additional services apart from sand casting?

A: Yes, SourcifyChina offers additional services such as machining, post-processing, quality inspections, surface treatments, and assembly to provide a comprehensive manufacturing solution.

Q: How does SourcifyChina ensure quality in sand casting parts?

A: We have stringent quality control measures, including material certification, dimensional inspections, non-destructive testing, and final product inspections to ensure each part meets your specifications.

Q: What are the payment terms at SourcifyChina?

A: Generally, we require a deposit and the balance to be paid upon delivery. We offer flexible payment options and can discuss terms based on the project size and client relationship.

Q: Can SourcifyChina handle large volume production orders?

Here are some tips to help you source sand casting services from SourcifyChina factory efficiently:

1. Specify Requirements:

Clearly outline your requirements including material type, dimensions, tolerances, and surface finish. This ensures the factory understands your needs precisely.

2. Experience & Expertise:

Verify the factory’s experience in sand casting and request to see examples of similar past projects. Experienced factories are more likely to deliver high-quality products.

3. Certifications:

Check for ISO or other relevant certifications to ensure quality management standards are met.

4. Request Samples:

Ask for samples or a prototype to assess the quality of their work before committing to a large order.

5. Communication:

Ensure effective communication by designating a point of contact who is fluent in your language. Miscommunications can lead to costly errors.

6. Lead Time:

Discuss and agree on lead times upfront. Confirm that the factory can meet your deadlines consistently.

7. Quality Control:

Establish a quality control process. Request detailed inspection reports and consider third-party inspections if necessary.

8. Payment Terms:

Clarify payment terms and conditions. Be cautious about upfront payments; milestones or progress payments can mitigate financial risks.

9. Sustainability:

Inquire about the factory’s environmental practices. Sustainable practices can be crucial for long-term partnerships and corporate responsibility.

10. Logistics:

Plan logistics thoroughly. Understand shipping costs, tariffs, and lead times. Partner with reliable freight forwarders.

11. References & Reviews:

Seek reviews and references from previous customers. Feedback from other clients can provide valuable insights into the factory’s reliability and quality of work.

By following these tips, you can effectively source sand casting services from SourcifyChina factory, ensuring a smooth and successful partnership.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.