SourcifyChina: Your Reliable Stamping Factory Supplier for High-Quality Manufacturing Solutions

Discover top-notch, reliable stamping solutions with SourcifyChina, your trusted factory supplier. Ensure high-quality manufacturing and precision in every product, backed by years of expertise and excellence.

Choosing SourcifyChina Factory for your stamping supplier needs in China offers numerous benefits. Their commitment to quality ensures top-notch products, meeting international standards and specifications. This attention to detail guarantees that your requirements are not just met but exceeded, providing a seamless and reliable supply chain experience.

SourcifyChina provides competitive pricing without compromising quality. Their efficient production processes and strong supplier relationships enable cost savings, making them an ideal partner for businesses seeking affordable yet high-quality stamping solutions. These cost advantages can significantly impact your bottom line, enhancing your overall profitability and market competitiveness.

With a focus on customer satisfaction, SourcifyChina offers exceptional service and support. From initial inquiry to post-purchase assistance, their responsive team ensures smooth communication and timely responses. This customer-centric approach helps build strong, long-term relationships, ensuring that your business needs are always prioritized and addressed promptly.

SourcifyChina Factory also emphasizes innovation and continuous improvement. By staying updated with the latest industry trends and technologies, they consistently enhance their capabilities and product offerings. This commitment to innovation ensures that you receive cutting-edge stamping solutions that align with the evolving demands of your market and industry.

In addition, SourcifyChina’s extensive industry experience and expertise provide a competitive edge. Their deep understanding of the stamping industry and manufacturing processes allows them to offer tailored solutions that meet specific requirements. This expertise translates into high precision, reliability, and efficiency in every product they deliver.

Choosing SourcifyChina Factory means partnering with a reliable, cost-effective, and innovative supplier. Their unwavering commitment to quality, competitive pricing, excellent customer service, and industry expertise makes them the ideal choice for businesses seeking a trustworthy stamping supplier from China. This partnership ensures your success in an increasingly competitive global market.

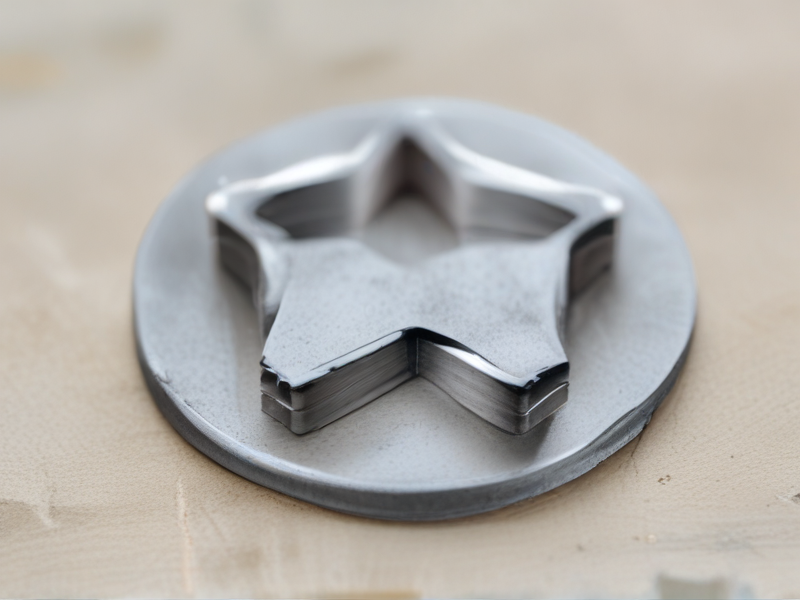

A stamping supplier provides metal stamping services, which involve the process of pressing, punching, or forming metal sheets into specific shapes. Various types of stamping suppliers offer different capabilities and services to meet diverse industry needs.

– Progressive Die Stamping: Efficient for high-volume production.

– Transfer Die Stamping: Suitable for large, complex parts.

– Single Hit Stamping: Best for low-volume production or prototype parts.

– Fine Blanking: Provides high precision and smooth edges.

– Deep Draw Stamping: Ideal for producing deep or hollow shapes.

– Short Run Stamping: Customizable for small quantities and unique designs.

– Fourslide Stamping: Offers intricate bends and complex parts.

– Coil Stamping: Continuous stamping from a coiled strip of metal for high efficiency.

– Custom Stamping: Tailored solutions to meet specific design requirements.

– Rapid Prototyping: Fast turnaround for prototype development.

– Secondary Operations: Additional services like tapping, welding, or assembly.

– Material Options: Stamping suppliers may offer a variety of materials including steel, aluminum, brass, copper, and more.

Stamping suppliers provide essential components for various industries by offering precise and efficient metal stamping services. Their applications span numerous sectors, enhancing production processes and product quality.

– Automotive Industry: Production of car parts such as brackets, clamps, and engine components.

– Electronics: Manufacturing of housings, connectors, and shielding for electronic devices.

– Aerospace: Creation of lightweight, durable parts for aircraft and spacecraft.

– Medical Devices: Production of surgical instruments and medical equipment parts.

– Consumer Goods: Fabrication of metal components for appliances, tools, and hardware.

– Construction: Manufacturing of metal brackets, frames, and structural components.

– Energy Sector: Production of components for renewable energy systems, including wind turbines and solar panels.

– Agricultural Equipment: Stamping parts for machinery used in farming and food production.

– Telecommunications: Creation of parts for communication devices and infrastructure.

– Defense Industry: Production of components for military equipment and vehicles.

– HVAC Systems: Manufacturing of parts for heating, ventilation, and air conditioning systems.

– Packaging: Creation of metal packaging solutions and containers.

These applications highlight the versatility and importance of stamping suppliers in modern manufacturing and production.

SourcifyChina is a reputable stamping supplier known for high-quality materials. They source premium metals such as stainless steel, aluminum, and brass, ensuring durability and strength in their stamped components.

Their stainless steel offerings are particularly notable for their resistance to corrosion and oxidation, making them ideal for applications in harsh environments. This ensures longevity and reliability for various industrial uses.

Aluminum is another key material, valued for its lightweight and excellent conductivity. SourcifyChina provides stamped aluminum parts that are crucial in automotive, aerospace, and electronics industries due to their versatility and performance.

Brass, with its exceptional machinability and resistance to corrosion, is also used by SourcifyChina. It is favored for components requiring precise manufacturing and aesthetic appeal, often found in plumbing and decorative applications.

SourcifyChina’s commitment to quality is evident in their rigorous material selection and testing processes. By using top-grade metals, they deliver parts that meet stringent industry standards, ensuring customer satisfaction and product excellence.

SourcifyChina is a leading stamping supplier known for its stringent quality control in the manufacturing process. Their procedure begins with a detailed inspection of raw materials, ensuring that only the best inputs are used.

Throughout production, SourcifyChina employs advanced machinery and regular monitoring to maintain precision and consistency. Each stamping process is meticulously checked by skilled technicians to prevent defects.

The company uses state-of-the-art testing equipment to measure product dimensions and tolerances. This ensures that all components meet exact specifications and industry standards.

Finally, SourcifyChina performs thorough final inspections before delivery. This comprehensive approach guarantees high-quality, reliable stamping products that meet customer requirements and enhance satisfaction.

SourcifyChina is a premier stamping supplier known for its high-quality production capabilities. The company specializes in a wide range of metal stamping services, catering to diverse industrial needs.

Their advanced manufacturing facilities are equipped with state-of-the-art machinery, ensuring precision and efficiency in every project. SourcifyChina prides itself on using cutting-edge technology to meet rigorous quality standards.

In addition to high-quality production, SourcifyChina offers customized solutions tailored to specific client requirements. Their experienced engineering team collaborates closely with clients to deliver bespoke products that match exact specifications.

SourcifyChina is also committed to sustainability and cost-effectiveness, employing environmentally friendly practices and materials. This commitment helps clients reduce their carbon footprint while maintaining competitive pricing.

Customer satisfaction is a cornerstone of SourcifyChina’s operations, with a dedicated support team ensuring timely delivery and exceptional service. This customer-centric approach has earned them a solid reputation in the industry.

Overall, SourcifyChina stands out as a reliable partner for metal stamping solutions, combining advanced technology, customization, sustainability, and exceptional customer service. Their comprehensive capabilities make them a preferred choice for businesses seeking high-quality, efficient, and eco-friendly stamping services.

Choosing a reputable stamping supplier can significantly enhance manufacturing efficiency and product quality. Here are the key benefits:

– Precision and Consistency: Suppliers offer high-quality, uniform parts essential for reliable product performance.

– Cost Efficiency: Bulk production reduces material waste and labor costs, leading to significant savings.

– Advanced Technology: Access to the latest stamping machinery and techniques ensures superior results.

– Customization: Ability to meet specific design and production requirements for various industries.

– Scalability: Easily adjusts to increasing or fluctuating production demands.

– Quick Turnaround: Efficient processes minimize lead times, speeding up time-to-market.

– Material Expertise: Suppliers provide expert knowledge on materials best suited for your needs.

Stamping suppliers are essential partners in manufacturing, providing precision metal parts for various industries. Their features ensure quality, efficiency, and customization.

– Precision Engineering: Stamping suppliers use advanced machinery and technology to produce parts with high accuracy and consistency.

– Material Variety: They offer a wide range of materials, including steel, aluminum, brass, and copper, to meet diverse industry needs.

– Customization: Suppliers provide bespoke solutions, tailoring parts to specific designs and requirements.

– Volume Capability: Capable of handling both small and large production runs, ensuring scalability.

– Quality Assurance: Rigorous quality control processes are in place to maintain high standards.

– Cost Efficiency: Competitive pricing and efficient production methods reduce overall costs.

– Speed and Efficiency: Quick turnaround times and streamlined operations enhance productivity.

– Technical Support: Expertise and support are available to assist with design and engineering challenges.

– Sustainability Practices: Many suppliers implement eco-friendly practices, including recycling and waste reduction.

– Regulatory Compliance: Adherence to industry standards and regulations ensures compliance and safety.

– Prototyping Services: Offering prototyping to validate designs before full-scale production.

– Innovative Solutions: Continuous improvement and innovation in techniques and processes.

These features make stamping suppliers indispensable for producing high-quality, reliable metal components efficiently.

SourcifyChina is a reputable stamping supplier specializing in high-quality custom products. Their expertise includes precision metal stamping, catering to diverse industries like automotive, electronics, and consumer goods.

Each project at SourcifyChina is handled with meticulous attention to detail. They offer tailored solutions, ensuring that every product meets the client’s specific requirements and industry standards.

Their advanced machinery and skilled workforce enable them to produce complex and precise stamped components. This commitment to quality ensures reliability and durability in all their products.

In addition to manufacturing, SourcifyChina provides comprehensive project management services. They assist clients from the initial design phase through to final production, ensuring seamless execution and timely delivery.

SourcifyChina’s customer-centric approach and dedication to innovation make them a trusted partner for businesses seeking high-quality stamping solutions. Their focus on continuous improvement ensures they stay at the forefront of the industry.

SourcifyChina is a prominent stamping supplier based in China, specializing in the production of high-quality metal stamping components for various industries. Leveraging advanced technology and a highly skilled workforce, the company offers a comprehensive range of services including precision stamping, deep drawing, and progressive die stamping. With a strong focus on innovation and efficiency, SourcifyChina ensures that each product meets stringent international quality standards, catering to clients across automotive, electronics, and consumer goods sectors. Their commitment to excellence is evident in their robust quality control processes and their ability to deliver customized solutions tailored to the unique needs of their global clientele. By maintaining competitive pricing without compromising on quality, SourcifyChina has established itself as a reliable partner in the manufacturing industry, consistently delivering products that enhance operational performance and drive business success for their customers.

In the Aerospace, Defense, and Marine industries, stamping suppliers play a critical role in manufacturing precise, high-strength components essential for various applications. Stamping involves shaping metal sheets into specific forms, often using high-tonnage presses, to create parts like brackets, enclosures, and structural components. In aerospace, the stringent requirements for weight reduction and durability necessitate the use of advanced materials such as titanium and aluminum alloys. Stamping suppliers must meet rigorous quality standards and certifications to ensure that each component can withstand the extreme conditions encountered in flight, including high stress, vibration, and temperature fluctuations.

Similarly, in the Defense sector, stamped components are vital for the reliability and functionality of military equipment and vehicles. These parts are designed to endure harsh environments and heavy use, ensuring operational readiness and safety. Stamping suppliers produce components such as armor plating, weapon mounts, and electronic enclosures, which must adhere to precise specifications and standards. In the Marine industry, stamping is used to create corrosion-resistant components for ships and submarines, including bulkheads, frames, and engine parts. These components must withstand the rigors of the marine environment, such as saltwater corrosion and high pressures, making the quality and precision provided by stamping suppliers indispensable for the safety and longevity of marine vessels.

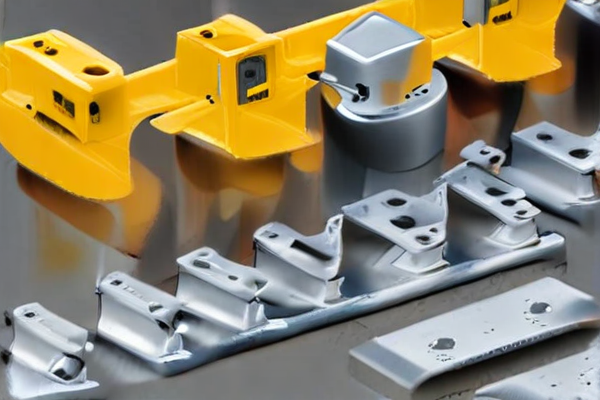

Stamping suppliers play a critical role in the automotive industry by providing precision-formed metal components essential for vehicle assembly and functionality. These suppliers use advanced stamping techniques to produce parts such as chassis components, engine brackets, transmission parts, and body panels, which require high durability and exact specifications. The ability to mass-produce these components with consistency and precision ensures that automotive manufacturers can maintain high standards of safety, performance, and efficiency in their vehicles. Additionally, with the shift towards electric vehicles (EVs), stamping suppliers are increasingly involved in producing components for battery housings and electric motor parts, adapting to new materials and designs to meet the evolving needs of the industry.

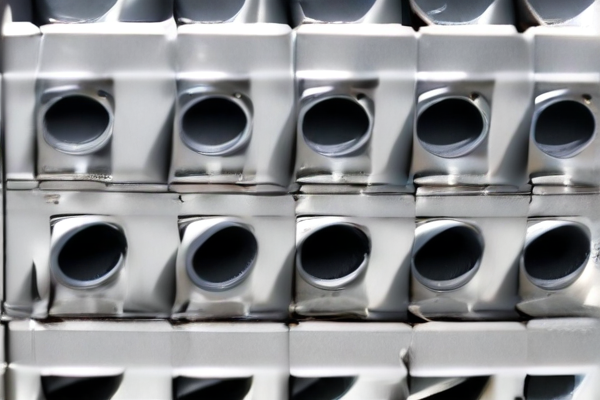

In the electronics sector, stamping suppliers are vital for manufacturing intricate metal components used in a wide range of devices. These include connectors, shielding cases, and various micro-components for consumer electronics like smartphones, laptops, and wearables. The precision and miniaturization required in electronics demand high-accuracy stamping processes to ensure reliability and functionality. As electronics continue to advance with trends like miniaturization and increased connectivity, stamping suppliers must innovate with new techniques and materials to meet stringent industry requirements. Their ability to produce high volumes of complex parts efficiently supports the rapid development and production cycles of the electronics industry, ultimately contributing to the delivery of cutting-edge technology to consumers.

In the construction industry, stamping suppliers play a critical role by providing high-precision metal components essential for building infrastructure. These components include brackets, connectors, and framing parts, which are foundational in constructing durable and safe structures. Stamping suppliers utilize advanced machinery to create parts with exact specifications, ensuring consistency and reliability in construction projects. The ability to produce large volumes of uniform components quickly and cost-effectively helps construction companies meet tight deadlines and maintain budget constraints. Moreover, the precision of stamped parts contributes to the overall integrity and longevity of buildings, reducing the need for frequent repairs and maintenance.

In the energy sector, stamping suppliers are indispensable for the production of various components used in energy generation and distribution. For instance, they manufacture parts for wind turbines, solar panels, and electrical transformers. The precision and durability of these stamped components are crucial, as they must withstand harsh environmental conditions and high operational stresses. By providing high-quality parts, stamping suppliers enable energy companies to maintain efficient and reliable systems. Additionally, the scalability of stamping production allows for rapid advancements in renewable energy technologies, supporting the global shift towards sustainable energy solutions. Overall, the expertise of stamping suppliers ensures the seamless operation and continual innovation within the energy industry.

Stamping suppliers play a critical role in the industrial equipment industry by providing essential components through metal stamping processes. This manufacturing method involves pressing sheet metal into specific shapes and sizes, producing parts that are crucial for the assembly and functionality of industrial machinery. The precision and efficiency of stamping make it ideal for producing large volumes of uniform parts, such as brackets, enclosures, and complex metal components, which are fundamental to the integrity and performance of industrial equipment. Stamping suppliers cater to various sectors within the industry, including automotive, aerospace, and heavy machinery, ensuring that each component meets stringent quality and durability standards.

The application of stamping suppliers extends beyond mere component production; it encompasses value-added services like design assistance, material selection, and post-processing treatments. By collaborating with stamping suppliers, industrial equipment manufacturers can streamline their production processes, reduce lead times, and enhance the overall quality of their products. These suppliers often employ advanced technologies such as progressive die stamping, which allows for multiple stamping operations in a single pass, thereby increasing efficiency and reducing waste. Additionally, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems enables precise customization and rapid prototyping, ensuring that even the most complex specifications are met. In essence, stamping suppliers are integral to the innovation and operational success of the industrial equipment industry.

Medical devices often require components with high precision and reliability, and stamping suppliers play a crucial role in meeting these demands. Stamping suppliers provide essential parts such as metal contacts, springs, and enclosures that are integral to the functionality of medical devices. The stamping process, which involves cutting, shaping, and forming metal sheets into specific shapes and sizes, allows for the mass production of components with exacting tolerances. This precision is critical in medical applications where even slight deviations can affect the performance and safety of devices like pacemakers, surgical instruments, and diagnostic equipment. By leveraging advanced stamping techniques, suppliers can ensure that medical device manufacturers receive components that meet stringent regulatory standards and quality requirements.

Additionally, the expertise of stamping suppliers in material selection and surface treatment is vital for the durability and biocompatibility of medical device components. Metals used in these devices, such as stainless steel, titanium, and various alloys, must withstand sterilization processes and resist corrosion while maintaining their mechanical properties. Stamping suppliers often collaborate closely with medical device manufacturers to develop custom solutions that address specific application needs, such as ensuring components are free from contaminants and have smooth, burr-free edges to prevent tissue damage. This collaboration extends to the prototyping stage, where suppliers can provide rapid iterations and adjustments to designs, enabling faster time-to-market for new medical technologies. Thus, stamping suppliers are indispensable partners in the medical device industry, contributing to the creation of reliable and safe products that improve patient care.

In the machining and manufacturing industry, stamping suppliers play a critical role by providing precision components through the stamping process. Stamping involves placing flat sheet metal into a stamping press where a tool and die surface forms the metal into a desired shape. This method is highly efficient for producing large volumes of parts with consistent quality and high precision. Stamping suppliers cater to various industries, including automotive, aerospace, electronics, and appliances, offering parts such as brackets, clips, and complex components that require intricate shapes and tight tolerances. Their capability to produce parts quickly and accurately significantly enhances the efficiency and cost-effectiveness of the manufacturing process.

Moreover, stamping suppliers contribute to the manufacturing ecosystem by offering value-added services like design assistance, prototyping, and secondary operations such as welding, assembly, and surface treatments. This end-to-end service capability helps manufacturers streamline their supply chains, reduce lead times, and improve overall product quality. By leveraging advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM), along with automated stamping presses, these suppliers ensure high repeatability and precision in part production. Consequently, partnering with a proficient stamping supplier allows manufacturers to focus on core operations while ensuring that their component needs are met with high-quality, cost-effective, and timely solutions.

What materials can SourcifyChina handle for stamping?

SourcifyChina can handle a variety of materials, including stainless steel, aluminum, brass, copper, and various alloys, ensuring high-quality stamping for diverse industrial applications.

What stamping processes does SourcifyChina offer?

SourcifyChina offers a range of stamping processes, including progressive die stamping, deep drawing, and transfer die stamping, to meet different production needs and specifications.

How does SourcifyChina ensure product quality?

SourcifyChina employs rigorous quality control measures, including in-process inspections, final product testing, and adherence to ISO 9001 standards. Advanced equipment and skilled technicians ensure high-quality outcomes.

Can SourcifyChina handle custom stamping projects?

Yes, SourcifyChina specializes in custom stamping projects. Our team works closely with clients to design and manufacture parts according to specific requirements, ensuring precision and quality.

What is the lead time for a stamping order?

Lead times vary based on project complexity and order volume. Typically, prototype orders take 2-3 weeks, while full production runs can take 4-6 weeks. We strive to meet client deadlines efficiently.

Does SourcifyChina provide prototyping services?

Yes, SourcifyChina offers prototyping services to help clients validate designs and make necessary adjustments before mass production, ensuring the final product meets all specifications.

What are the minimum order quantities (MOQs) for stamping?

SourcifyChina is flexible with MOQs, accommodating both small and large orders. We work with clients to meet their specific needs, whether for small batches or high-volume production.

How does SourcifyChina handle shipping and logistics?

SourcifyChina manages shipping and logistics efficiently, providing global delivery services. We handle all export documentation and ensure timely delivery to the client’s location.

Can SourcifyChina provide secondary operations and finishing services?

Yes, SourcifyChina offers a range of secondary operations such as welding, assembly, and surface finishing (e.g., plating, painting) to deliver fully finished parts ready for use.

How can I get a quote for my stamping project?

To get a quote, you can contact SourcifyChina through our website or email. Provide detailed information about your project, including material, dimensions, quantity, and any specific requirements, and we will respond promptly.

When working with a stamping supplier manufacturing in China, especially through a platform like Sourcify, it’s essential to ensure quality, efficiency, and reliability. Here are some key tips:

1. Research and Verification: Thoroughly research potential suppliers. Verify their credentials, certifications, and past performance. Use Sourcify’s vetting process to ensure the supplier meets industry standards.

2. Clear Specifications: Provide detailed specifications for your stamping requirements. Include materials, tolerances, finishes, and any special processes. Clear communication minimizes misunderstandings and errors.

3. Sample Approval: Request and approve samples before committing to large-scale production. This ensures the supplier understands your requirements and can produce to your standards.

4. Quality Control: Implement robust quality control measures. Regularly inspect production runs and consider third-party quality inspections. Sourcify can assist in coordinating these inspections.

5. Lead Times and Logistics: Clarify lead times and shipping logistics. Understand the supplier’s production schedule and ensure it aligns with your timelines. Factor in shipping times and customs processes.

6. Cost Analysis: Evaluate the total cost, including manufacturing, shipping, duties, and any potential tariffs. Sourcify can help negotiate favorable terms and pricing.

7. Communication: Maintain open and frequent communication. Use tools provided by Sourcify to stay updated on production status and address any issues promptly.

8. Contracts and Agreements: Have clear contracts outlining terms, conditions, payment schedules, and responsibilities. Ensure both parties understand the agreement to avoid disputes.

9. Cultural Sensitivity: Be aware of cultural differences and holidays that might affect production schedules. Building a good relationship with your supplier can lead to better cooperation and problem-solving.

10. Sustainability and Compliance: Ensure the supplier adheres to environmental and labor regulations. This not only ensures compliance with international standards but also promotes ethical manufacturing practices.

By following these tips, you can effectively manage your stamping supplier manufacturing process in China and leverage Sourcify’s resources to achieve successful outcomes.

1. What is SourcifyChina Factory?

SourcifyChina Factory is a platform that connects businesses with reliable Chinese manufacturers, specializing in a variety of industries including metal stamping.

2. How can I verify the quality of stamping suppliers listed on SourcifyChina Factory?

SourcifyChina Factory provides detailed profiles for each supplier, including certifications, quality control processes, and customer reviews to help you assess their reliability.

3. What types of stamping services do suppliers on SourcifyChina offer?

Suppliers on SourcifyChina offer a wide range of stamping services, including progressive die stamping, deep draw stamping, and precision metal stamping.

4. How do I start sourcing a stamping supplier from SourcifyChina Factory?

Begin by creating an account on SourcifyChina Factory, then search for stamping suppliers using specific keywords or browse by category. You can request quotes directly from suppliers through the platform.

5. Are there minimum order quantities (MOQs) for stamping services?

Yes, most suppliers have MOQs which vary depending on the complexity and volume of the stamping order. These details are typically provided on the supplier’s profile.

6. How do I communicate with suppliers on SourcifyChina Factory?

Communication can be conducted through the SourcifyChina platform’s messaging system, allowing you to discuss project details, negotiate prices, and track orders.

7. What payment methods are accepted by stamping suppliers on SourcifyChina Factory?

Suppliers usually accept various payment methods including wire transfers, credit cards, and sometimes PayPal. It’s best to confirm payment terms directly with the supplier.

8. Can I visit the stamping supplier’s factory?

Many suppliers welcome factory visits. Arrangements can be made directly with the supplier, and SourcifyChina may assist in coordinating visits.

9. How are shipping and logistics handled?

Shipping and logistics are typically managed by the supplier. They offer various shipping options and will provide shipping quotes based on your delivery preferences.

10. What if I encounter issues with a supplier?

SourcifyChina Factory offers support to resolve disputes and issues with suppliers. Contact their customer service for assistance in handling any problems.

Sourcing a stamping supplier from SourcifyChina factory can be streamlined with these steps:

1. Define Requirements: Clearly specify the types of stamping processes and materials needed. Detail the volume requirements, tolerances, and quality standards.

2. Research Suppliers: Start by searching for suppliers on SourcifyChina’s platform. Utilize filters to narrow down options by industry, certifications, and capabilities.

3. Verify Credentials: Look for ISO certifications, production capabilities, and past client reviews. A reputable supplier should be transparent with their credentials.

4. Initial Contact: Reach out to shortlisted suppliers with a detailed Request for Information (RFI). Ask about their experience, production capabilities, lead times, and pricing.

5. Sample Request: Request samples to evaluate the quality and precision of their work. Assess the material finish, dimensional accuracy, and overall quality.

6. Factory Visit: If feasible, arrange a visit to the supplier’s factory. This helps verify their production capabilities and quality control processes firsthand.

7. Quality Assurance: Inquire about their quality assurance measures. Reliable suppliers should have stringent QC processes and should provide quality certificates.

8. Negotiation: Discuss pricing, payment terms, and delivery schedules. Ensure the terms are favorable and transparent.

9. Contracts: Draft a clear contract outlining all terms, including quality standards, delivery schedules, and penalties for non-compliance.

10. Pilot Run: Before full-scale production, consider a pilot run to ensure the supplier can meet your specifications consistently.

By following these steps, you can effectively source a reliable stamping supplier through SourcifyChina, ensuring quality and efficiency in your production processes.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.