Technology and Applications of steel 1045

Steel 1045, also known as medium carbon steel, is widely used in various industries due to its favorable mechanical properties and versatility. Composed primarily of iron and carbon, with a carbon content of 0.43%-0.50%, it strikes a balance between strength, hardness, and ductility. Here’s an overview of its technology and applications:

Technology

Manufacturing Process:

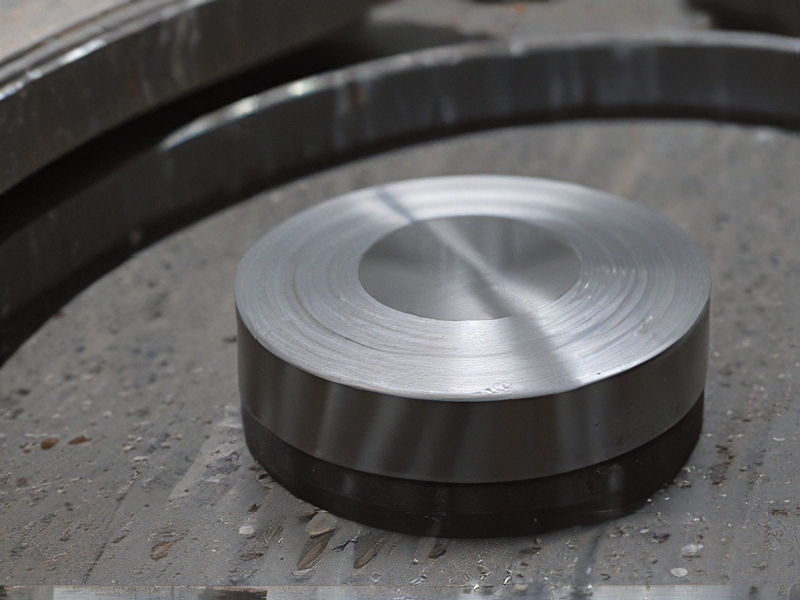

Steel 1045 is typically produced through processes such as hot rolling, cold drawing, or forging. The steel is heated and shaped into desired forms, followed by controlled cooling to enhance its mechanical properties.

Heat Treatment:

To further improve its properties, 1045 steel undergoes heat treatment processes like annealing, normalizing, quenching, and tempering. These treatments adjust the steel’s hardness, tensile strength, and toughness, making it suitable for specific applications.

Applications

Automotive Industry:

Steel 1045 is commonly used in automotive components such as gears, shafts, axles, and crankshafts due to its excellent machinability and balance of strength and toughness.

Construction and Machinery:

In construction, 1045 steel finds use in structural components, bolts, and rods. Its durability and wear resistance make it suitable for machinery parts like spindles, couplings, and pins.

Agricultural Equipment:

The steel’s robustness is ideal for agricultural machinery, including plowshares, tiller blades, and other components that require wear resistance and high strength.

Tool and Die Making:

Steel 1045 is also used in the manufacture of tools and dies, such as drill collars and machine tool spindles, where precise hardness and strength are crucial.

Advantages

Versatility:

1045 steel’s adaptability to various heat treatments allows for customization of its mechanical properties to meet specific requirements.

Cost-Effectiveness:

Compared to higher alloy steels, 1045 offers a cost-effective solution without compromising on performance for medium-strength applications.

Machinability:

Its good machinability ensures ease of fabrication and maintenance, making it a preferred choice in many industrial applications.

In summary, steel 1045’s balance of properties, cost-effectiveness, and versatility makes it a staple material across multiple industries, fulfilling diverse functional requirements efficiently.

Quality Testing Methods for steel 1045 and how to control quality

Quality testing methods for steel 1045 typically include both destructive and non-destructive techniques to ensure material properties meet specifications. Non-destructive methods such as ultrasonic testing (UT) and magnetic particle inspection (MPI) are used to detect surface and subsurface defects without damaging the material. UT utilizes sound waves to detect internal flaws, while MPI identifies surface irregularities using magnetic fields.

For destructive testing, methods like tensile testing assess the mechanical properties of steel, including strength and ductility. This involves pulling a sample until it fractures, providing data on its ultimate tensile strength and yield strength. Hardness testing, using methods like Rockwell or Brinell hardness tests, measures steel’s resistance to indentation, which correlates with its strength and wear resistance.

To control quality, stringent procedures are essential throughout manufacturing. This includes precise chemical composition control during steelmaking to ensure consistency in mechanical properties. Heat treatment processes such as annealing or quenching must adhere to specific temperature and time parameters to achieve desired hardness and toughness. Regular calibration and maintenance of testing equipment are crucial to obtaining accurate results.

Furthermore, implementing a robust quality management system (QMS) helps monitor processes, detect deviations, and ensure compliance with standards. Continuous improvement through feedback loops and corrective actions based on testing results enhances overall quality and reliability of steel 1045 products.

Tips for Procurement and Considerations when Purchasing from steel 1045

When procuring steel 1045, a medium-carbon steel known for its strength and hardness, consider the following tips and considerations:

1. Supplier Reputation: Choose suppliers with a strong reputation for quality and reliability. Verify their certifications and compliance with industry standards.

2. Material Specifications: Clearly define the material specifications, including chemical composition and mechanical properties, to ensure you get the desired grade and performance.

3. Application Requirements: Understand the specific requirements of your application. Steel 1045 is suitable for parts requiring high strength and wear resistance but may need heat treatment to achieve desired hardness.

4. Heat Treatment: Consider the heat treatment processes (such as quenching and tempering) necessary for your application. Discuss these needs with your supplier to ensure the material is delivered in the appropriate condition.

5. Machinability: Steel 1045 has good machinability in the annealed condition but may require specific machining techniques after heat treatment. Plan for the appropriate tools and processes to handle this.

6. Dimensional Tolerances: Specify the required dimensional tolerances and surface finish to avoid any issues in the final application.

7. Cost: Balance the cost against the material performance. While 1045 steel offers good value, ensure the price reflects the quality and processing requirements.

8. Delivery and Lead Times: Confirm delivery schedules and lead times to avoid disruptions in your production timeline. Reliable logistics can be crucial for maintaining workflow.

9. Compliance and Certification: Ensure the steel meets all regulatory and safety standards relevant to your industry. Request necessary certification and documentation from your supplier.

10. Sustainability: Consider the environmental impact and look for suppliers who follow sustainable practices and provide eco-friendly materials.

By keeping these considerations in mind, you can make informed decisions that ensure the quality, performance, and cost-effectiveness of your procurement process.

FAQs on Sourcing and Manufacturing from steel 1045 in China

Certainly! Here are some FAQs regarding sourcing and manufacturing steel 1045 in China:

1. What is steel 1045?

Steel 1045 is a medium-carbon steel known for its good strength, toughness, and wear resistance properties. It is commonly used in machinery parts, shafts, gears, and similar applications.

2. Why source steel 1045 from China?

China is a leading producer of steel globally, offering competitive pricing and access to advanced manufacturing capabilities. Chinese manufacturers can often provide cost-effective solutions for bulk orders.

3. How to find reliable suppliers in China?

Use online platforms like Alibaba or global trade fairs such as Canton Fair to connect with verified steel manufacturers. Conduct thorough due diligence, including verifying certifications and visiting facilities if possible.

4. What are the quality standards for steel 1045 from China?

Ensure suppliers adhere to international standards like ASTM A108 for chemical composition, ASTM A29 for mechanical properties, and ISO 683-3 for heat treatment requirements. Request test certificates and samples to verify quality.

5. How can I manage production and quality control?

Establish clear specifications and quality requirements in your contract with the supplier. Engage a third-party inspection agency to monitor production processes and perform quality checks before shipment.

6. What are common challenges when sourcing steel 1045 from China?

Potential challenges include language barriers, differences in business practices, and logistical complexities. Effective communication and establishing a strong relationship with your supplier are crucial for mitigating these issues.

7. How can I ensure compliance with import regulations?

Understand import regulations in your country regarding steel products from China, including tariffs, customs duties, and compliance with safety standards (e.g., REACH regulations in the EU).

8. What are the typical lead times for manufacturing steel 1045 in China?

Lead times can vary depending on the order size and production schedule. Discuss timelines and production capacities with your supplier to align expectations.

Navigating sourcing and manufacturing steel 1045 from China involves careful planning, rigorous quality control, and clear communication to ensure successful outcomes.