Technology and Applications of thin sheet of plastic

Technology and Applications of Thin Plastic Sheets

Thin plastic sheets, typically less than a millimeter thick, are highly versatile materials used across various industries due to their flexibility, durability, and cost-effectiveness. These sheets are made from different types of plastics, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polyethylene terephthalate (PET).

Key Technologies:

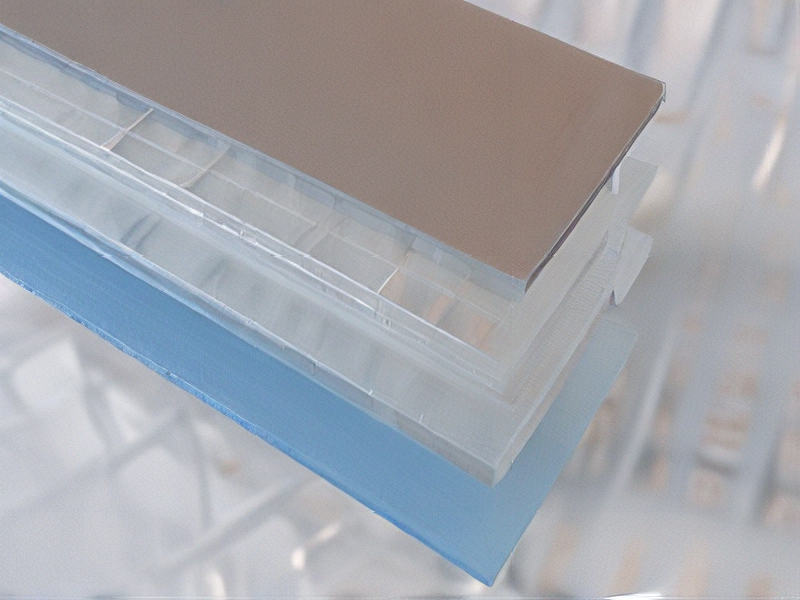

1. Extrusion: This process involves melting plastic pellets and forming them into continuous sheets through a die. It’s widely used for producing plastic films and sheets in large volumes.

2. Calendering: In this method, heated plastic is passed through rollers to achieve the desired thickness. It’s particularly used for PVC sheets.

3. Blow Molding: Used mainly for creating thin plastic films, this technique involves extruding molten plastic into a tube, inflating it to form a bubble, and then flattening it into a sheet.

4. Lamination: Thin plastic sheets are often laminated with other materials to enhance their properties, such as strength, barrier protection, or aesthetic appeal.

Applications:

1. Packaging: Thin plastic sheets are ubiquitous in packaging for food, beverages, and consumer goods due to their lightweight nature, durability, and ability to provide a moisture barrier.

2. Agriculture: Used as greenhouse films and mulch films, these sheets help in controlling the environment for optimal plant growth.

3. Construction: They serve as vapor barriers, damp-proof membranes, and protective covers, ensuring moisture control and protection in buildings.

4. Healthcare: In medical settings, thin plastic sheets are used for sterile packaging, disposable drapes, and protective covers.

5. Electronics: Thin plastic films are integral in manufacturing flexible electronic devices, display screens, and solar panels due to their insulating properties and flexibility.

6. Printing and Graphics: They are used as substrates for signs, posters, and other graphic applications, offering durability and ease of printing.

Thin plastic sheets, through advancements in technology, continue to find new applications, driven by their adaptability and functional benefits.

Quality Testing Methods for thin sheet of plastic and how to control quality

Quality testing methods for thin sheets of plastic typically involve both destructive and non-destructive techniques to ensure consistent quality and durability. Non-destructive methods include:

1. Visual Inspection: Examining the surface for defects like scratches, bubbles, or discoloration.

2. Dimensional Measurement: Using calipers or micrometers to verify thickness and dimensions.

3. Optical Methods: Utilizing optical microscopy or digital imaging to detect microscopic defects.

4. Surface Roughness Measurement: Assessing the smoothness of the sheet using profilometers.

Destructive testing methods involve:

1. Tensile Testing: Determining mechanical strength by stretching samples until they break.

To control quality, implement these strategies:

1. Establish Specifications: Define acceptable tolerances for thickness, dimensions, and defects.

2. Regular Sampling: Take samples at regular intervals during production.

3. Statistical Process Control (SPC): Monitor production using statistical methods to catch deviations.

4. Training and Standards: Train staff on quality standards and ensure adherence to procedures.

5. Feedback Loops: Implement feedback systems to address issues promptly.

By employing these methods and controls, manufacturers can maintain high standards and ensure thin plastic sheet products meet customer expectations reliably.

Tips for Procurement and Considerations when Purchasing from thin sheet of plastic

When procuring thin sheets of plastic, consider the following tips to ensure you make the right purchasing decisions:

1. Material Type: Identify the specific type of plastic required (e.g., PVC, PET, acrylic) based on your application’s needs for durability, flexibility, and transparency.

2. Thickness and Size: Determine the appropriate thickness and dimensions of the sheets needed. This depends on factors like strength requirements and manufacturing processes.

3. Quality Standards: Ensure that the supplier meets quality standards such as ISO certifications or industry-specific standards to guarantee the plastic’s performance and longevity.

4. Supplier Reliability: Choose a supplier with a reputation for reliability in delivering consistent quality, on-time shipments, and responsive customer service.

5. Cost Considerations: Compare prices from different suppliers while considering factors like shipping costs, bulk discounts, and any additional services offered (e.g., custom cutting).

6. Environmental Impact: Assess the environmental impact of the plastic material and supplier practices. Opt for recyclable or sustainable options where possible.

7. Customization Options: If needed, inquire about customization capabilities such as color matching, surface treatments (e.g., matte finish), or special formulations (e.g., UV-resistant).

8. Compatibility: Verify that the plastic sheets are compatible with your manufacturing processes, including ease of fabrication (cutting, bending, molding) if applicable.

9. Supplier Support: Evaluate the level of technical support or advice offered by the supplier to assist in choosing the right material and addressing any challenges that may arise.

10. Long-term Relationship: Building a long-term relationship with a trusted supplier can lead to better service, cost savings, and access to new product developments.

By focusing on these considerations, you can effectively procure thin plastic sheets that meet your project requirements while ensuring quality, cost-effectiveness, and sustainability.

FAQs on Sourcing and Manufacturing from thin sheet of plastic in China

FAQs on Sourcing and Manufacturing Thin Sheet Plastic in China

1. Why source thin sheet plastic from China?

China offers competitive pricing, a wide range of suppliers, and advanced manufacturing capabilities. The extensive network of factories can produce various types of plastics, including polyethylene, polypropylene, and PVC.

2. What are the common types of thin sheet plastics available?

Common types include PVC, PET, PE, PP, and PS. Each has distinct properties suitable for different applications, such as packaging, printing, and protective coverings.

3. How to find reliable suppliers?

Use platforms like Alibaba, Global Sources, and Made-in-China. Vet suppliers by checking their certifications, requesting samples, and reading reviews. Visiting factories or hiring a third-party inspection service can also ensure reliability.

4. What certifications should suppliers have?

Look for ISO 9001 for quality management, ISO 14001 for environmental management, and product-specific certifications like FDA approval for food-grade plastics.

5. What is the typical lead time?

Lead times can vary but generally range from 15 to 45 days depending on the order size, customization needs, and supplier capacity.

6. What are the minimum order quantities (MOQs)?

MOQs vary by supplier and product type, typically ranging from 500 kg to several tons. Negotiating with suppliers can sometimes reduce MOQs.

7. What are the common challenges?

Challenges include communication barriers, quality control, and logistics. Mitigate these by establishing clear specifications, using contracts, and maintaining regular communication.

8. How to handle quality control?

Implement stringent quality checks, request pre-shipment inspections, and consider third-party inspection services to ensure product standards are met.

9. What about shipping and logistics?

Work with experienced freight forwarders. Understand shipping terms (FOB, CIF, etc.), customs regulations, and tariffs to avoid unexpected costs.

10. How to ensure compliance with regulations?

Ensure products meet the regulatory standards of your target market (e.g., REACH, RoHS). Suppliers should provide necessary documentation and test reports.

By addressing these key points, businesses can effectively source and manufacture thin sheet plastic from China, leveraging the country’s robust industrial ecosystem.