Choosing SourcifyChina Factory for water jet services offers a blend of reliability and efficiency. The factory boasts state-of-the-art equipment, ensuring precise and high-quality cutting. Their extensive experience in the industry guarantees that all projects meet rigorous standards.

Furthermore, SourcifyChina provides exceptional customer support, ready to assist buyers at every step. Their dedicated team is fluent in English, facilitating smooth communication and timely responses. This commitment to service means clients experience minimal delays and assurances of project alignment with specifications.

Additionally, SourcifyChina maintains competitive pricing without compromising on quality. They offer flexible pricing models tailored to suit different budget requirements, making high-quality water jet services accessible. This affordability, combined with their unwavering quality standards, makes them a sensible choice for businesses.

Lastly, SourcifyChina employs strict quality control measures throughout the production process. Each project undergoes rigorous inspection phases to ensure accuracy and consistency. Clients can rest assured, knowing their water jet cutting needs are met with excellence and precision every time.

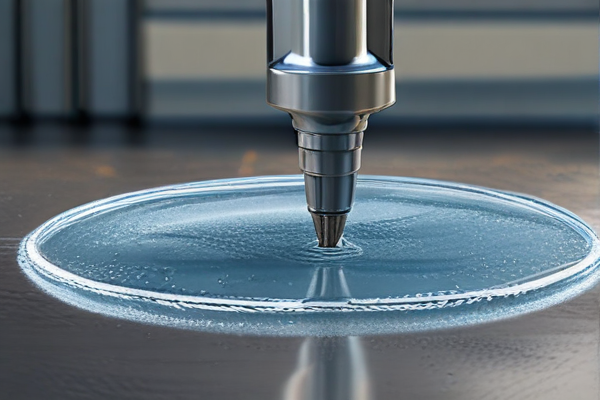

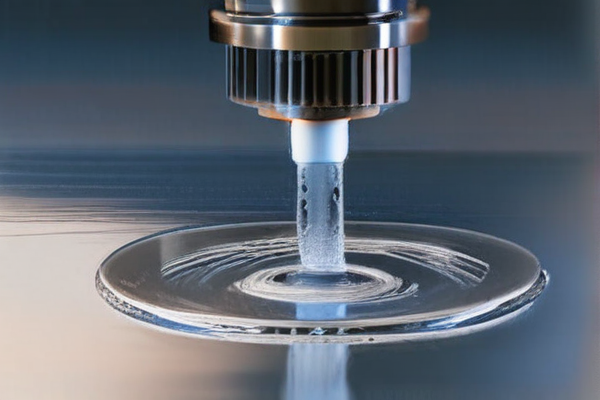

Water jet services utilize high-pressure water streams to cut, shape, and clean various materials. Known for precision and versatility, they cater to industries ranging from manufacturing to construction.

– Abrasive Water Jet Cutting: Ideal for cutting hard materials like metals, stone, and ceramics. It involves adding abrasive particles to the water stream for enhanced cutting power.

– Pure Water Jet Cutting: Uses only high-pressure water, perfect for softer materials like rubber, foam, and wood.

– Cleaning and Deburring: Utilized for removing contaminants, coatings, or burrs from surfaces, commonly employed in aerospace, automotive, and industrial maintenance.

– Hydrodemolition: A method for removing damaged concrete while preserving structural integrity, widely used in construction and civil engineering.

– Surface Preparation: Prepares surfaces for painting, coating, or bonding by removing old layers and contaminants, used in maritime, oil, and gas industries.

– Precision Cutting: Delivers intricate and precise cuts in materials like glass and composite materials, supporting industries such as electronics and artistic ventures.

– Food Industry Applications: Used for cutting food products with minimal waste and high sanitary standards, beneficial in food processing and packaging sectors.

These diverse water jet services can adapt to various needs, ensuring high-quality results across multiple fields.

Water jet services utilize high-pressure water streams to cut, clean, or shape materials in various industries. These versatile applications deliver precise and efficient results without damaging the material’s integrity.

– Manufacturing: Cutting complex shapes in metal, plastic, and glass components.

– Automotive: Cutting and finishing of car parts like gaskets and panels.

– Aerospace: Precision cutting of components for aircraft, ensuring high safety standards.

– Construction: Demolition and concrete cutting, offering a dust-free solution.

– Shipbuilding: Removal of old paint and rust from hulls without using chemicals.

– Food Processing: Cutting of food products like meat and vegetables without contamination.

– Medical Devices: Manufacturing intricate and sterile parts such as surgical instruments.

– Art and Design: Creating detailed sculptures, engravings, or custom designs.

– Electronics: Cutting circuit boards and other delicate components.

– Mining: Safe cutting and shaping of mineral deposits.

SourcifyChina offers premium water jet cutting services, leveraging advanced technology to deliver precise cuts on a variety of materials. Their high-pressure water jets can handle metals, ceramics, glass, plastics, and composites with remarkable accuracy and minimal thermal impact.

Stainless steel is a popular material for water jet cutting due to its durability and resistance to corrosion. SourcifyChina excels in processing stainless steel, ensuring edges are clean and components are precision-crafted to meet exact specifications.

Another key material is aluminum, prized for its lightweight properties and excellent machinability. Water jet cutting preserves the integrity of aluminum, making it ideal for aerospace, automotive, and industrial applications.

Glass cutting with water jet technology allows for intricate designs without the risk of cracking or shattering. SourcifyChina employs techniques that maintain clarity and smooth edges, ideal for architectural and decorative projects.

Plastics and composites also benefit from water jet services, as the process does not introduce heat, preventing warping or melting. This makes it suitable for manufacturing components in electronics, medical devices, and consumer goods.

By offering versatile and high-precision water jet services, SourcifyChina ensures that clients receive tailored solutions that meet their specific material needs. Whether working with metal, glass, or composites, their technology supports a wide array of industries, delivering both quality and efficiency. This commitment to excellence positions SourcifyChina as a leader in the domain of water jet cutting services.

SourcifyChina’s water jet services ensure precision and quality at every step. Advanced CAD software designs each project meticulously, minimizing human error and maximizing exactness.

Raw materials undergo stringent inspection to verify they meet high standards. Only approved materials proceed to the cutting process, ensuring durability and efficiency in the final product.

Operators are rigorously trained, ensuring they handle both machinery and software adeptly. Regular training updates keep them aligned with technological advancements, contributing to impeccable cutting accuracy.

The cutting process is monitored in real-time through advanced sensors. These sensors detect inconsistencies and immediately alert operators, minimizing defects and ensuring consistent quality.

After cutting, products undergo thorough inspections. Dimensional accuracy and edge quality are checked against specifications, utilizing high-precision measuring instruments to guarantee exact matches.

Finished products receive a final quality assessment before packaging. This comprehensive evaluation ensures each piece meets SourcifyChina’s high standards, reinforcing customer trust and satisfaction. The consistent excellence in their water jet services results from these meticulous quality control measures.

SourcifyChina’s commitment to quality control in water jet services not only assures the high precision and reliability of their products but also highlights their dedication to customer satisfaction and industry-leading standards. This meticulous approach makes them a trusted partner in manufacturing, consistently delivering superior results.

SourcifyChina offers advanced water jet services, renowned for precision cutting of diverse materials like metal, stone, and composites. The accuracy preserves material integrity and accommodates intricate designs effortlessly.

Our water jet capabilities extend to industrial applications, ensuring no thermal distortion. This cold-cutting process is perfect for sensitive materials, reducing waste and maintaining quality throughout production.

With high pressure and velocity, our water jets handle thick materials up to several inches, maintaining clean edges and reducing the need for secondary finishing. This efficiency streamlines operations and maximizes productivity.

Specializing in custom solutions, SourcifyChina’s expertise covers automotive, aerospace, and architectural sectors. Utilizing state-of-the-art technology, we adapt to specific needs, delivering exceptional results consistently.

By integrating cutting-edge software with our water jets, we achieve unmatched intricacy and repetition, ideal for mass production. Our team’s expertise guarantees projects are completed on time and within budget.

Committed to sustainability, our water jet services minimize environmental impact. Using eco-friendly abrasives, we promote green manufacturing while meeting stringent industry standards. Trust SourcifyChina for precision, efficiency, and environmental responsibility in every water jet cutting task.

Water jet services offer a versatile and efficient solution for various cleaning and cutting tasks, leveraging high-pressure water streams to deliver precise results without damaging underlying surfaces.

– Eco-Friendly: Water jet cutting and cleaning use only water and abrasive materials, reducing the need for harmful chemicals and minimizing environmental impact.

– Precision: High-pressure water jets can achieve fine cuts and detailed cleaning, making them ideal for intricate designs and delicate surfaces.

– Versatility: Suitable for a wide range of materials, including metal, stone, glass, and composites, offering broad application possibilities in different industries.

– Time Efficiency: Rapid cutting and cleaning reduce operational downtime, enhancing productivity for businesses.

– Safety: Eliminating the need for toxic chemicals reduces health risks to operators and reduces hazardous waste production.

– Material Preservation: Non-thermal cutting prevents heat-affected zones, preserving the integrity and properties of the material.

– Cost-Effective: Reduces wear and tear on equipment and can lower the overall cost of labor and materials in the long run.

– Minimal Waste: The precision of water jet services ensures minimal material wastage, contributing to cost savings and environmental benefits.

In summary, water jet services provide an effective, safe, and environmentally responsible method for various cleaning and cutting applications, offering significant benefits in terms of precision, versatility, and efficiency.

Water jet services offer precision cutting capabilities, utilizing high-pressure water streams to slice through materials without generating heat or causing material distortion. This technology is versatile and used in various industries for its accuracy and efficiency.

Key Features:

– Precision Cutting: Delivers accurate cuts with tolerances as tight as ±0.003 inches, ensuring exact specifications.

– Versatility: Capable of cutting a wide range of materials, including metals, plastics, ceramics, and composites.

– Cold Cutting Process: No heat is produced, preserving the material’s structural integrity and eliminating the risk of heat-affected zones.

– Minimal Material Wastage: Narrow kerf width creates less material waste, making it cost-effective.

– Eco-Friendly: Uses water and abrasives, reducing the need for harmful chemicals and generating minimal environmental impact.

– Complex Shapes: Can produce intricate and complex geometries that other cutting methods may struggle with.

– Thickness Capability: Efficiently cuts thin sheets as well as thick materials, from fractions of an inch up to several inches thick.

– Speed and Efficiency: Offers quick setup times and rapid cutting speeds, improving overall productivity.

– Smooth Edges: Produces clean and smooth edges, reducing the need for secondary finishing processes.

– Multi-Head Configurations: Some machines can be equipped with multiple cutting heads, increasing throughput by processing multiple parts simultaneously.

– Programmable: Easily integrates with CNC systems for automated and repeatable cuts.

These features make water jet services an ideal solution for precision cutting needs across numerous applications, from industrial manufacturing to artistic creations.

SourcifyChina offers top-tier water jet services known for precision and versatility. Utilizing advanced technology, they cater to a myriad of industries requiring intricate cuts. From metals to composites, their expertise is unmatched.

They provide custom products tailor-made for specific needs, ensuring each piece meets the highest standards. Whether for industrial machinery or artistic endeavors, their accuracy guarantees flawless execution.

SourcifyChina’s projects range from small scale prototypes to large manufacturing runs. Their team collaborates closely with clients, ensuring all requirements are met. This dedication fosters long-term partnerships and repeat business.

In summation, SourcifyChina delivers exceptional water jet services, custom products, and comprehensive project support. Their commitment to quality, precision, and client satisfaction sets them apart in the industry.

SourcifyChina Water Jet Services is a renowned provider specializing in high-precision waterjet cutting solutions tailored to meet the diverse needs of industries in China and beyond. Leveraging advanced waterjet technology, they offer unparalleled cutting accuracy and versatility across a wide range of materials, including metals, stones, composites, and glass. This innovative technique ensures clean, smooth edges without the thermal distortion typical of traditional cutting methods. With a commitment to excellence, SourcifyChina collaborates closely with clients throughout the project lifecycle, from initial design consultations to final product delivery, guaranteeing customized solutions that align with specific operational requirements and aesthetic standards. By prioritizing quality, efficiency, and customer satisfaction, SourcifyChina Water Jet Services stands out as a trusted partner for businesses seeking to enhance their manufacturing processes through precision engineering and cutting-edge technology.

Water jet services have become an indispensable tool in the aerospace and defense sectors, where precision and reliability are paramount. This cutting-edge technology employs high-pressure water mixed with abrasives to accurately slice through a variety of materials, including metals, composites, and polymers. In aerospace applications, water jets excel in manufacturing and maintaining crucial components such as turbine blades, panels, and complex structural elements. The technique’s ability to produce intricate cuts without generating excessive heat (a common byproduct of traditional cutting methods) preserves the material’s integrity and mechanical properties. This non-thermal process is particularly advantageous in producing high-tolerance parts that have to withstand extreme conditions, such as those encountered in aviation and space exploration.

In the marine industry, water jet services similarly offer unparalleled benefits, aiding in both the construction and maintenance of ocean-going vessels. Marine environments impose strict demands on materials, requiring high durability and resistance to corrosive saltwater. Water jet cutting can efficiently produce precise, complex parts from robust materials like stainless steel and aluminum, vital for crafting hulls, deck structures, and specialized equipment. Additionally, the method minimizes material waste and reduces the risk of introducing structural weaknesses, thereby improving overall vessel reliability and longevity. The defense sector also leverages water jet services for the rapid prototyping and production of critical equipment and components, ensuring timely deployment of advanced technologies and enhancing operational readiness. From armored vehicle components to submarine parts, water jet cutting meets the stringent standards required for military applications, where precision and durability can be matters of national security.

Water jet services have revolutionized the automotive industry by providing a precise, clean, and efficient way to cut various materials used in vehicle manufacturing. In automotive applications, water jets are employed to cut metals, composites, and plastics, which are integral parts of car frames, interiors, and engine components. The capability of water jets to cut through tough materials without causing thermal distortion ensures that the structural integrity and properties of these materials are maintained. This precision cutting reduces waste, enhances the accuracy of component fitting, and ultimately improves the overall quality and performance of vehicles. Moreover, the flexibility of water jet cutting enables automation in assembly lines, contributing to faster production times and lower manufacturing costs.

Similarly, in the electronics industry, water jet services shine by providing high-precision cutting needed for the intricate and delicate components found in modern electronic devices. The non-thermal nature of water jet cutting preserves the integrity of sensitive materials such as glass, ceramics, and certain metals used in the manufacturing of circuit boards, displays, microchips, and various other components. This technology ensures that the cuts are clean and precise, which is critical for maintaining the functionality and reliability of electronic parts. Additionally, the capability to execute complex and intricate patterns without physically damaging the material extends to prototyping and custom designs, supporting innovation and rapid development in electronics. By incorporating water jet services, electronics manufacturers benefit from enhanced precision, minimized material waste, and the ability to meet the demanding tolerances required in modern electronics production.

Water jet services have revolutionized the construction industry through their precise cutting capabilities and environmentally friendly approach. Utilizing high-pressure streams of water mixed with abrasive materials, water jets can slice through a variety of construction materials including concrete, steel, and glass with remarkable precision. Unlike traditional cutting methods, water jet cutting produces no heat-affected zones, thereby maintaining the integrity and structural properties of the materials being cut. This feature is particularly beneficial in demolition projects and retrofitting older structures, as it minimizes damage to surrounding areas. Moreover, the dust-free operation of water jets significantly reduces health hazards and environmental pollution, making construction sites safer and cleaner.

In the energy sector, water jet services are invaluable for their efficiency, precision, and non-invasive nature. They are extensively used in the maintenance and dismantling of energy facilities, including nuclear plants, where precision and safety are paramount. For instance, water jets can be employed to decommission obsolete pipelines or to remove coatings and corroded materials from turbines and reactors without causing secondary contamination. Additionally, water jet cutting is instrumental in the fabrication of parts used in renewable energy installations, such as wind turbine blades and solar panels. By transitioning to water jet technology, the energy sector can achieve significant operational efficiencies and adhere to stringent environmental and safety regulations.

The industrial equipment industry has seen remarkable advancements with the integration of water jet services, which utilize highly pressurized water streams mixed with abrasive materials to cut, shape, and clean a wide range of materials. This technology is particularly advantageous in applications requiring high precision and minimal thermal impact. Unlike traditional cutting methods that can generate significant heat and potentially alter the material properties, water jet cutting keeps the material relatively cool, preserving its structural integrity. This capability is invaluable for industries that work with sensitive metals, composites, and even delicate materials like glass or ceramics. Water jet services also offer a high degree of flexibility, as they can cut complex shapes and intricate patterns with minimal setup time, making them ideal for both large-scale manufacturing and custom, one-off projects.

In addition to cutting, water jet services are also utilized for surface preparation and cleaning in the industrial equipment sector. The high-pressure water jets can effectively remove coatings, rust, and other contaminants from equipment surfaces, ensuring they are clean and ready for subsequent processes like painting or welding. This method is environmentally friendly, as it often reduces the need for harsh chemical cleaners and minimizes waste. Moreover, water jet cleaning is highly efficient, reducing downtime and increasing the lifespan of industrial machinery by maintaining its optimal operating condition. Overall, the incorporation of water jet services in the industrial equipment industry not only enhances manufacturing precision and efficiency but also promotes sustainability and equipment longevity.

Water jet services have seen a significant application in the medical device industry due to their precision and versatility. Utilizing high-pressure water streams, these services allow for the meticulous cutting and shaping of a wide range of medical-grade materials such as stainless steel, titanium, and specialized polymers. This non-contact cutting method minimizes thermal stress and avoids any mechanical deformation, which is crucial when manufacturing sensitive and high-precision devices like stents, surgical tools, and implantable components. The accuracy of water jet cutting ensures that delicate features and intricate geometries can be achieved without compromising material integrity, thus improving the overall reliability and performance of the medical devices.

Moreover, water jet technology enhances the efficiency and cleanliness of the manufacturing process. Traditional cutting methods often generate heat and leave behind burrs or other imperfections that require additional post-processing. In contrast, water jet cutting produces smooth, burr-free edges, reducing the need for secondary finishing work and therefore shortening production times. This is particularly beneficial for the stringent hygiene standards in the medical industry, as it minimizes the risk of contamination. Additionally, with the ability to cut multiple layers of material simultaneously, water jet services enable the scalable and rapid production of complex medical devices, meeting the growing demand for high-quality healthcare solutions.

Water jet services are a crucial aspect of both machining and manufacturing, leveraging high-pressure streams of water, often mixed with abrasive materials, to cut a variety of materials with exceptional precision. This process is especially valuable in industries that require intricate and accurate cuts, such as aerospace, automotive, and electronics. Water jet cutting can handle materials ranging from metals and composites to glass and ceramics, making it versatile for numerous applications. Unlike traditional machining methods, water jet services do not generate heat, thus eliminating the risk of heat-affected zones which can alter the material properties or cause deformation. This cold cutting technique preserves the integrity of the material, ensuring high-quality outcomes with minimal waste.

In manufacturing, water jet services offer significant advantages, including the ability to process larger sheets of material more efficiently than conventional cutting methods. This increases production speed and reduces material costs, which is vital for large-scale manufacturing projects. The absence of harmful fumes or gases during the cutting process makes water jet cutting a more environmentally friendly option compared to techniques like laser cutting. Additionally, the precision of water jet services allows for tight tolerances and fine details, which are critical in producing components that meet stringent industry standards. Overall, water jet services enhance both the flexibility and efficiency of machining and manufacturing processes, providing a reliable solution for cutting complex shapes and achieving high-quality finishes.

Sure, here’s a concise FAQ for manufacturing “water jet services quality work from SourcifyChina factory”:

Q1: What materials can your water jet services cut?

A1: Our water jet services can cut a wide range of materials including metals, glass, stone, composites, ceramics, rubber, and plastics.

Q2: What is the maximum thickness your water jet cutter can handle?

A2: Our water jet cutters can handle materials up to 6 inches thick, though the optimal thickness may vary based on the material type.

Q3: How precise is your water jet cutting process?

A3: Our water jet cutting technology offers precision within ± 0.1 mm, ensuring high-quality, accurate cuts for intricate designs and patterns.

Q4: What are the advantages of using water jet cutting over other methods?

A4: Water jet cutting offers several benefits including no heat-affected zones, minimal material waste, smooth edges that often require no additional finishing, and the capability to cut complex shapes.

Q5: Can you handle large production runs?

A5: Yes, SourcifyChina factory is equipped to handle both small and large production runs, maintaining consistent quality throughout.

Q6: Do you offer custom water jet cutting services?

A6: Absolutely. We provide fully customized water jet cutting services tailored to your specifications and project requirements.

Q7: How do I submit a design for water jet cutting?

A7: You can submit your design files in CAD, DXF, or other compatible formats through our website or email. Our team will review and optimize them for cutting.

Q8: What is your turnaround time for water jet cutting projects?

A8: Turnaround time varies based on project complexity and volume, typically ranging from a few days to a couple of weeks. We strive to meet your deadlines efficiently.

Q9: How do you ensure the quality of your water jet cutting services?

A9: We adhere to strict quality control processes, including pre-cutting inspections and post-cutting reviews to ensure that every piece meets your specifications.

Q10: What are the costs associated with water jet cutting services at SourcifyChina?

A10: Pricing depends on material type, thickness, complexity of the design, and order volume. Contact us for a detailed quote based on your project needs.

When considering water jet services for manufacturing from SourcifyChina factory, there are several key tips to ensure successful collaboration and optimal results. Water jet cutting is a versatile and precise method used for a variety of materials, including metals, plastics, and composites.

1. Define Your Requirements: Clearly specify your project requirements, including material types, dimensions, tolerances, and any special features. Precise specifications help ensure the factory can meet your expectations.

2. Material Compatibility: Confirm that the SourcifyChina factory can handle the specific materials you need. Water jet cutting works well with various materials, but some may require specialized handling.

3. Quality Standards: Inquire about the factory’s quality control processes. Ensuring they meet international standards will help maintain the consistency and reliability of the final products.

4. Experience and Expertise: Look into the factory’s experience with similar projects. Experienced operators will be more adept at managing intricate designs and tight tolerances.

5. Technology and Equipment: Verify that the factory uses up-to-date and well-maintained machinery. Modern water jet cutters offer improved precision and efficiency.

6. Cost Efficiency: Discuss pricing structures upfront. Some factories offer discounts for bulk orders, so understanding their pricing model can help you manage costs effectively.

7. Communication: Establish clear and continuous communication channels. Misunderstandings can lead to costly errors, so regular updates and feedback are crucial.

8. Sample and Prototyping: Request samples or prototypes before full-scale production. This step ensures that the output meets your requirements and allows for any adjustments.

9. Lead Time: Understand the production timelines and align them with your project deadlines. Factor in potential delays to avoid bottlenecks.

10. Logistics: Plan for efficient shipping and logistics. SourcifyChina should provide comprehensive shipping solutions, including customs handling and tracking.

By following these tips, you can effectively leverage SourcifyChina’s water jet services for your manufacturing needs, ensuring high-quality and cost-efficient production.

Sure, here is a list of Frequently Asked Questions (FAQs) with answers for sourcing water jet services from SourcifyChina factory:

Q: What is SourcifyChina’s water jet services?

A: SourcifyChina specializes in precise and high-quality water jet cutting services, delivering intricate designs and shapes by using high-pressure water streams to cut a variety of materials.

Q: What materials can SourcifyChina’s water jet services handle?

A: Our water jet cutting services can handle a wide range of materials including metals, composites, glass, ceramics, rubber, plastics, and various types of stone.

Q: What is the maximum thickness SourcifyChina’s water jet can cut?

A: Our advanced water jet cutting machinery can cut materials up to 200mm (approximately 8 inches) thick, providing flexibility for various project requirements.

Q: How precise is SourcifyChina’s water jet cutting process?

A: Our water jet cutting technology offers high precision with tolerance levels as tight as ±0.1mm, ensuring accurate and clean cuts for complex designs.

Q: What are the turnaround times for water jet cutting services?

A: Turnaround times vary depending on the project complexity and volume, but most orders are processed within 7-14 days. Expedited services are available upon request.

Q: Are there any minimum order requirements?

A: Yes, typically there is a minimum order requirement depending on the project specifications. Please contact us for details tailored to your specific needs.

Q: Do you assist with design customization?

A: Absolutely, we provide full design assistance and can work with your CAD files or help create designs from scratch to meet your exact requirements.

Q: How do I request a quote for water jet services from SourcifyChina?

A: You can request a quote by visiting our website, filling out the quote request form with your project details, or contacting our customer service team directly through email or phone.

Q: What information should I provide for an accurate quote?

A: To provide an accurate quote, please include material type, thickness, dimensions, quantity, and any specific design files or drawings related to your project.

Q: What quality assurance measures are in place?

A: SourcifyChina implements stringent quality control processes, including in-process inspections and final quality checks, ensuring that all parts meet your specifications and industry standards.

Sourcing water jet services from a factory in China via Sourcify can be streamlined with these practical tips:

1. Clear Specifications: Clearly define your requirements, including materials, thickness, tolerances, and dimensions. Detailed specifications help avoid misunderstandings and ensure the factory delivers what you need.

2. Evaluate Factory Capabilities: Not all factories have the same capabilities. Ensure the factory has advanced water jet cutting technology and skilled operators. Assess their prior projects and request samples if possible.

3. Request Quotations: Obtain detailed quotations from multiple factories. Compare prices, lead times, and services offered. Sourcify can facilitate this by connecting you with pre-vetted manufacturers.

4. Check Quality Standards: Verify the factory’s quality control processes. Look for certifications like ISO 9001 and inquire about their quality assurance practices to ensure high standards.

5. Communication: Maintain clear and regular communication. Use project management tools provided by Sourcify to track progress and address any issues promptly.

6. Negotiate Terms: Discuss payment terms, shipping arrangements, and warranties. Ensure all agreements are documented in a formal contract to protect your interests.

7. Consider Lead Times: Factor in the production and shipping lead times. Plan your order accordingly to avoid delays in your supply chain.

8. Intellectual Property Protection: Ensure your designs and data are protected. Non-disclosure agreements (NDAs) can provide an added layer of security.

9. Visit the Factory: If feasible, visit the factory to assess their capabilities and operations. This can provide valuable insights and strengthen your business relationship.

10. Leverage Sourcify’s Expertise: Utilize Sourcify’s platform to manage sourcing complexities, from identifying reliable suppliers to overseeing quality control.

By following these tips, you can efficiently source high-quality water jet services from SourcifyChina factory, ensuring a seamless manufacturing process.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.