Unraveling Cold Metal Transfer: Reliable Insights from SourcifyChina Factory

Cold Metal Transfer (CMT) is a breakthrough welding method pioneered by Fronius International. SourcifyChina Factory stands as a reliable source in showcasing how CMT reduces heat input, minimizes spatter, and improves weld quality, revolutionizing manufacturing processes.

Choosing SourcifyChina Factory for cold metal transfer (CMT) products in China ensures superior quality and reliability. They specialize in advanced CMT technology, providing high-precision products ideal for various industries. With SourcifyChina, buyers benefit from reduced heat input and minimal distortion, thanks to their cutting-edge processes and experienced team.

SourcifyChina’s competitive pricing and efficient supply chain management make them an attractive option for global buyers. Their commitment to timely deliveries and customized solutions caters to the specific needs of each client, enhancing overall satisfaction and fostering long-term business relationships.

Moreover, the factory adheres to stringent quality control standards, ensuring each product meets international benchmarks. Their dedication to continuous improvement and innovation keeps them at the forefront of the industry, making them a preferred partner for many businesses.

In conclusion, SourcifyChina Factory is the ideal choice for buyers seeking reliable, high-quality cold metal transfer products from China, thanks to their superior technology, excellent service, and competitive pricing.

Cold Metal Transfer (CMT) is an advanced welding process that reduces heat input to materials, minimizing distortion and spatter. This technique enhances precision in welding thin metals and sensitive alloys.

Types and options for Cold Metal Transfer:

– CMT Standard: Ideal for basic welding applications, ensuring reduced heat input and minimal spatter.

– CMT Pulse: Combines traditional pulse welding with CMT for improved control and seam quality.

– CMT Advanced: Features adjustable parameters for specialized welding requirements, offering greater flexibility.

– CMT Twin: Uses two wire electrodes for higher efficiency and faster welding speeds.

– CMT Robot: Integrates CMT technology with robotic systems for automated, high-precision manufacturing tasks.

– CMT Pin: Specialized for welding thin and coated sheets, ensuring minimal coating damage.

– CMT Dynamic: Adjusts dynamically to changing welding conditions, maintaining consistent quality and precision.

Key considerations:

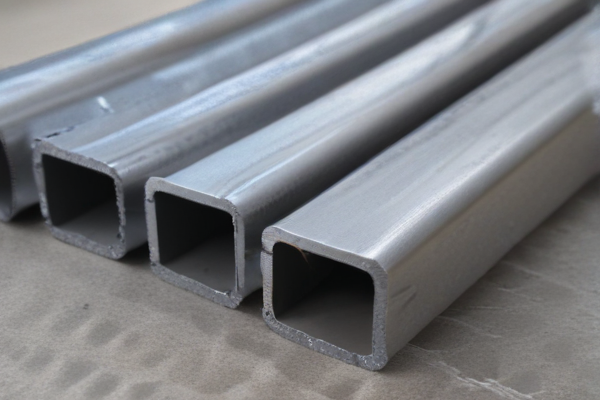

– Material Compatibility: Suitable for aluminum, stainless steel, and other sensitive metals.

– Reduced Distortion: Lower heat input helps in maintaining material integrity.

– Spatter Reduction: Offers cleaner welds with less post-processing.

– Ease of Use: Simplified setup and operation for consistent results.

– Applications: Widely used in automotive, aerospace, and precision manufacturing industries.

Benefits:

– Energy Efficiency: Reduces power consumption due to lower heat requirements.

– Flexibility: Adaptable to various materials and thicknesses.

– Improved Joint Quality: Produces strong, high-quality welds with minimal defects.

Overall, CMT provides a versatile and efficient solution for modern welding challenges, emphasizing precision, quality, and adaptability to a range of industrial needs.

Cold Metal Transfer (CMT) is an advanced welding technique recognized for its low-heat input, which minimizes distortion and spatter. This makes CMT ideal for joining thin materials, achieving high-quality welds, and reducing post-weld treatments.

Applications

of CMT:

– Automotive Industry: CMT is used for lightweight construction, particularly in welding thin aluminum sheets and mixed materials with minimal distortion.

– Aerospace: Precision welding of aluminum and titanium components, ensuring strong, lightweight structures without compromising material properties.

– Electronics: Fabrication of delicate parts where minimal thermal stress is paramount, such as in battery components and sensors.

– Shipbuilding: Joining various materials used in maritime structures with high efficiency and reduced manual rework.

– Medical Devices: Producing high-integrity, low-heat welds essential for delicate, stainless steel medical instruments and equipment.

– Construction: Structural welding of modern building materials, ensuring robust joints without the drawbacks of traditional high-heat methods.

– Furniture Manufacturing: Ensuring seamless, aesthetically pleasing joints in metal furniture assemblies, significantly reducing finishing work.

– Renewable Energy: Used in the production of solar panels and wind turbines where precision and minimal thermal distortion are crucial.

– Robotics: Optimal for automated welding systems requiring consistency and precision in high-volume production.

– Consumer Electronics: Reliability in joining small, intricate components in various gadgets and appliances.

– Railway Industry: Welding lightweight carriages and components, enabling efficient manufacturing while retaining structural integrity.

Cold Metal Transfer technology’s versatility and precision make it a valuable asset across multiple industries, optimizing welding processes and improving overall product quality.

Sure! Here’s a concise explanation:

1. Introduction

Cold Metal Transfer (CMT) is an advanced welding technique that minimizes heat input, reducing thermal distortion. Pioneered by Fronius, CMT is increasingly popular in industrial applications.

2. Process Description

In CMT, a quick, controlled dip transfer of the wire into the weld pool is utilized. This is facilitated by precise digital control, ensuring minimal spatter and improved consistency.

3. Advantages

Key benefits of CMT include reduced heat-affected zones, excellent gap-bridging capabilities, and the ability to weld thin materials effectively. It’s also well-suited for welding dissimilar metals.

4. Industrial Applications

Industries such as automotive, aerospace, and construction employ CMT to enhance productivity and quality. It’s particularly valued for joining lightweight and delicate components.

5. Conclusion

Overall, Cold Metal Transfer represents a significant advancement in welding technology, offering precise control and efficiency. Its growing adoption underscores its value in modern manufacturing processes.

SourcifyChina is a reputable company specializing in quality control and manufacturing services across various industries. One of their specialized techniques is Cold Metal Transfer (CMT), which is a precise welding process beneficial for joining thin materials with minimal heat distortion.

CMT stands out for its low heat input, reducing the likelihood of burn-through and spatter. This is achieved through an innovative technique where the welding wire is controlled in a push-pull manner, maintaining a stable arc. This precision makes it ideal for delicate materials and high-quality finishes.

During the quality control phase, SourcifyChina employs rigorous testing and inspection methods to ensure the integrity of each weld. These methods can include visual inspection, radiographic testing, and ultrasonic testing, among others. This comprehensive approach ensures that the final product meets stringent quality standards.

To sum up, SourcifyChina’s expertise in the Cold Metal Transfer process, combined with their stringent quality control measures, makes them a trusted partner for manufacturing high-quality metal components. Their meticulous attention to detail ensures that clients receive products that meet exact specifications and function reliably.

SourcifyChina offers advanced manufacturing solutions, and one of their standout capabilities is Cold Metal Transfer (CMT). This technology is renowned for its precision and efficiency in metal welding and joining processes. It uses a unique method to control heat input, significantly reducing spatter and distortion.

CMT’s low-heat technique ensures that even thin and heat-sensitive materials can be welded with minimal risk of warping or damaging surrounding areas. This makes it especially advantageous for high-quality, intricate projects requiring impeccable attention to detail and finishing.

The technology is adaptable to various metals, enhancing its versatility for numerous industrial applications, including automotive, aerospace, and construction. By leveraging CMT, SourcifyChina ensures optimal results with improved structural integrity and aesthetic quality of the final products.

In addition to performance, CMT is also advantageous in energy efficiency and cost-effectiveness, as it reduces the need for excessive rework and material waste. This aligns with SourcifyChina’s commitment to sustainable and economical manufacturing practices.

By offering Cold Metal Transfer capabilities, SourcifyChina continues to push the envelope in technological innovation, ensuring high-quality, reliable, and efficient solutions for their clients’ manufacturing needs.

Cold Metal Transfer (CMT) is an advanced welding process that offers superior joining quality by significantly reducing heat input. This method enhances efficiency and precision in the welding process.

Benefits of Cold Metal Transfer:

– Reduced Heat Input: Minimizes thermal distortion, making it suitable for thin materials and heat-sensitive parts.

– Improved Weld Quality: Produces cleaner and stronger welds with minimal spattering.

– Greater Efficiency: Achieves higher process speeds and lowers post-weld cleanup time.

– Versatility: Capable of welding a variety of materials, including dissimilar metals.

– Less Material Deformation: Maintains better control over the welding process, leading to lower deformation and residual stress.

– Energy Savings: Lower power consumption compared to traditional welding methods.

– Automated Compatibility: Easily integrated with robotic systems for consistent and repeatable welds.

– Economic Benefits: Reduced rework and material waste lead to cost savings.

Cold Metal Transfer (CMT) is an advanced welding technique that offers precise control over heat input, significantly reducing spatter and distortion during the welding process. This cutting-edge technology ensures high-quality, reliable welds.

– Low Heat Input: CMT minimizes the amount of heat applied, reducing the risk of warping and other thermal distortions.

– Spatter Reduction: This method decreases spatter significantly, leading to cleaner welds and less post-weld cleanup.

– Enhanced Control: Offers precise control over the welding process, making it ideal for delicate or intricate applications.

– Material Versatility: Compatible with a wide range of materials, from aluminum and stainless steel to more exotic alloys.

– Improved Efficiency: Faster welding speeds contribute to increased productivity and reduced downtime.

– Energy Efficiency: Lower energy consumption compared to traditional welding methods, contributing to cost savings.

– Seam Quality: Produces smooth, high-quality seams with minimal post-processing required.

– User-Friendly: Advanced automation features make it easier to achieve consistent results, even for less experienced operators.

– Reduced Fume Emission: Less fume generation contributes to a cleaner working environment and improves operator safety.

– Applicability to Thin Sheets: Particularly effective for welding thin sheets without burn-through, preserving material integrity.

Overall, Cold Metal Transfer revolutionizes the welding industry by combining efficiency, precision, and versatility, making it an ideal choice for diverse welding applications.

SourcifyChina is a leading provider of customized products and projects tailored specifically to meet client requirements. They specialize in delivering high-quality, unique solutions covering a wide range of industries and applications.

One of the advanced techniques they employ is Cold Metal Transfer (CMT). CMT is a welding method that minimizes heat input, reducing distortion and spatter. This results in cleaner, precise welds, especially beneficial for thin materials and aluminum.

CMT’s innovative approach enhances product strength and durability. This method’s precision makes it ideal for both intricate and extensive projects, ensuring that the end products meet tight tolerances and specifications.

Incorporating CMT into their customized offerings allows SourcifyChina to deliver superior quality and performance. Whether for automotive, aerospace, or industrial applications, their expertise in CMT ensures that clients receive products that stand out in terms of durability and design.

SourcifyChina’s dedication to utilizing advanced techniques like CMT underscores its commitment to innovation and customer satisfaction. They consistently push the boundaries of what’s possible, offering solutions that are both effective and economically viable.

In summary, SourcifyChina excels in creating bespoke products and projects by leveraging cutting-edge techniques such as Cold Metal Transfer. Their focus on quality, precision, and innovation ensures that clients receive top-notch results tailored to their specific needs.

SourcifyChina, a leading force in the engineering and manufacturing sectors, has demonstrated its prowess with the innovative Cold Metal Transfer (CMT) technology. CMT, an advanced welding process, employs precise arc control to minimize heat input, enabling seamless joining of metals with reduced thermal distortion and spatter. This technique is particularly advantageous for sensitive materials like aluminum and stainless steel, where traditional welding methods often fall short. By leveraging CMT, SourcifyChina enhances product quality and durability, catering to diverse industries from automotive to aerospace. Their commitment to cutting-edge solutions underscores their role as a pivotal driver of industrial advancement in the modern manufacturing landscape.

Cold Metal Transfer (CMT) is a welding process widely appreciated for its precision and reduced heat input compared to traditional welding methods. In aerospace applications, CMT is particularly valuable due to its ability to join thin materials and dissimilar metals with minimal distortion and spatter. The reduced heat input of CMT leads to less thermal stress, making it suitable for welding delicate components such as aluminum skins and intricate airframe structures. This innovation ensures the integrity and strength of critical aerospace parts, which are often subjected to extreme environmental conditions and mechanical stresses. Furthermore, CMT’s precision and clean welds contribute to weight reduction by allowing the use of thinner materials without compromising structural integrity, which is paramount in aerospace design.

In the defense and marine sectors, CMT also proves to be a game-changer. Defense applications can benefit from CMT’s ability to weld armor and other high-strength materials with minimal heat distortion, maintaining the material’s protective properties. This is crucial for manufacturing vehicles and equipment that require both strength and precision. In marine applications, CMT’s proficiency in welding stainless steel and aluminum makes it ideal for constructing ship hulls, underwater equipment, and other components that endure corrosive environments. The process ensures robust and reliable joints that enhance the longevity and performance of marine vessels. Additionally, the ability to join dissimilar metals can aid in the repair and retrofit of existing marine infrastructure, providing cost-effective and efficient solutions without compromising quality. Overall, CMT’s innovative approach to welding offers significant advancements in the aerospace, defense, and marine industries.

Cold Metal Transfer (CMT) is a cutting-edge welding process that has garnered significant attention in automotive and electronics applications due to its unique approach to heat management and material deposition. In the automotive industry, CMT is particularly valued for its ability to join thin metals with minimal thermal distortion, making it ideal for welding parts of car bodies and frames that require precision and strength. The low heat input during the CMT process reduces the risk of warping and maintains the integrity of the base materials, leading to stronger and more durable welds. This is especially important for manufacturing components like exhaust systems, heat exchangers, and structural panels, where lightweight and high-strength materials are critical for enhancing fuel efficiency and safety.

In the realm of electronics, CMT offers substantial benefits by facilitating the welding of delicate and sensitive components without causing thermal damage. The precision offered by CMT is unmatched when it comes to applications such as assembling microelectronic packages, attaching connectors to circuit boards, or creating battery tabs for energy storage systems. The process allows for the use of fine wires and thin foils, which are common in electronic devices, while maintaining a clean, spatter-free weld. This ensures that the electrical properties and performance of the components are not compromised, which is crucial for the reliability and longevity of electronic products. Moreover, the repeatability and automation capabilities of CMT make it highly suitable for high-volume manufacturing environments, where consistent quality and efficiency are paramount.

Cold Metal Transfer (CMT) is an advanced welding technology that has been garnering attention in the construction industry due to its precision and reduced heat input. In conventional welding methods, high heat can lead to material distortion, residual stress, and even compromised structural integrity. CMT, however, mitigates these issues by utilizing a highly controlled arc that minimizes heat transfer to the base material. This makes it particularly suitable for welding thin sheets of metal, dissimilar materials, and delicate structures, often found in high-rise buildings, bridges, and complex architectural designs. The technology improves both weld quality and productivity, enabling construction projects to achieve higher standards of safety and durability while potentially lowering costs through reduced material waste and rework.

In the realm of energy applications, Cold Metal Transfer technology is proving to be invaluable, particularly in the fabrication and maintenance of energy infrastructure such as pipelines, wind turbines, and solar panel frameworks. The low-heat input characteristic of CMT allows for the creation of strong, reliable joints with minimal thermal stress, which is crucial for materials subjected to extreme environmental conditions. For example, pipelines transporting oil and natural gas require welds that can withstand high pressures and varying temperatures. CMT ensures these requirements are met by offering superior mechanical properties and corrosion resistance. Additionally, the precision and efficiency of CMT make it ideal for manufacturing the components of renewable energy systems, promoting more sustainable energy solutions through improved durability and longevity of essential infrastructure.

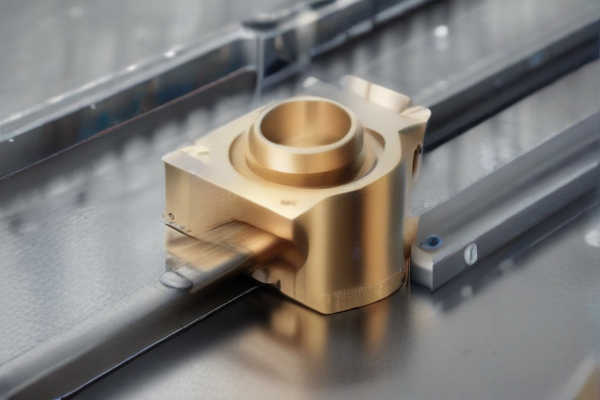

Cold Metal Transfer (CMT) is an advanced welding process that has revolutionized the industrial equipment industry by offering high-quality, efficient welding solutions. CMT is a variant of Gas Metal Arc Welding (GMAW) that meticulously controls the heat input and reduces spatter, making it ideal for welding thin materials and dissimilar metals. The process involves a low heat signature where the welding wire retracts slightly upon contacting the workpiece, allowing for precision droplet deposition and minimizing thermal distortion. This precise heat management makes CMT excellent for applications requiring minimal thermal impact, such as in the manufacturing of delicate machinery parts, precision components, and automotive assemblies.

The industrial equipment industry benefits significantly from CMT technology due to its enhanced efficiency, reduced material deformation, and improved weld quality. Industries such as aerospace, automotive, and electronics, which demand intricate and fine welding tasks, leverage CMT to produce superior and reliable joints. Additionally, CMT is valued for its versatility; it can weld various metals, including aluminum and high-strength steels, which are often used in equipment manufacturing for their lightweight and durable properties. The process’s low spatter characteristic contributes to cleaner working environments and lower post-weld cleanup costs, enhancing overall productivity and cost-effectiveness. As a result, CMT is increasingly becoming a go-to welding technology for complex industrial applications that require precision and reliability.

Cold Metal Transfer (CMT) is a versatile welding technology that is increasingly finding applications in the medical device industry. Characterized by its low heat input and precise control, CMT minimizes thermal distortion, making it ideal for joining thin-walled components and dissimilar materials. This low-heat process employs a controlled short-circuit metal transfer, which reduces spatter and delivers an exceptionally clean weld. In the medical field, where devices often feature compact and delicate structures, the precision and quality offered by CMT are invaluable. For instance, creating intricate components for medical implants, surgical instruments, and diagnostic devices benefits significantly from this method, ensuring high weld integrity and biocompatibility.

Furthermore, CMT’s capability to weld materials like titanium and stainless steel—commonly used in medical devices—enhances its applicability. Titanium, known for its excellent corrosion resistance and biocompatibility, is a preferred material for implants and orthopedic devices. However, conventional welding techniques can compromise these properties due to high thermal input. CMT minimizes these risks, preserving the mechanical and biological traits of the material. This innovation not only extends the longevity and reliability of medical devices but also simplifies the manufacturing process, leading to cost-effective production. As the medical industry continues to prioritize minimally invasive procedures and complex, high-precision devices, the adoption of Cold Metal Transfer can play a crucial role in meeting these advanced technological requirements.

Cold Metal Transfer (CMT) is an advanced welding technique developed by Fronius International GmbH. This process significantly reduces the heat input while joining metal components, making it ideal for applications demanding high precision and minimal thermal distortion. Unlike traditional welding methods, CMT employs a controlled dip-transfer method wherein the wire continually moves forward and backward, ensuring a stable arc and reducing spatter. The reduced heat allows for excellent control over the weld pool, enabling the welding of thin materials and dissimilar metal combinations with unprecedented ease. The process is particularly beneficial in industries where thermal damage could compromise the structural integrity of the components, such as aerospace, automotive, and electronics.

In machining and manufacturing, the application of Cold Metal Transfer technology provides several advantages. Its ability to weld thin metals without causing warping or excessive thermal stresses contributes to the production of high-quality components with fewer defects, thereby decreasing the need for rework or scrapping. This precision makes CMT suitable for the assembly of intricate parts and high-value components where dimensions and tolerances are critical. Additionally, its spatter-free welding means cleaner joints and less post-processing, significantly cutting down on production time and costs. As manufacturers increasingly seek efficiency, sustainability, and quality, the adoption of CMT in various sectors showcases its potential to redefine traditional welding practices, contributing to the innovation and improvement of modern manufacturing processes.

Sure, here are the FAQs for manufacturing “Cold Metal Transfer (CMT) quality work from SourcifyChina factory”:

1. What is Cold Metal Transfer (CMT)?

Cold Metal Transfer (CMT) is an advanced welding technology that reduces heat input, resulting in high-quality welds with minimal spatter. This process is particularly effective for joining thin metals and different material types, providing precise and clean welds.

2. What are the benefits of using CMT for my manufacturing needs?

CMT offers numerous advantages such as reduced heat input, improved weld quality, minimal distortion, lower spatter, and the ability to join dissimilar materials. These benefits result in higher productivity and cost savings in the manufacturing process.

3. Does SourcifyChina provide high-quality CMT work?

Yes, SourcifyChina specializes in high-quality CMT work. Our factory is equipped with state-of-the-art CMT welding machines that ensure precision and consistency in every project. Our experienced operators follow stringent quality control measures to meet and exceed industry standards.

4. What industries can benefit from CMT technology?

Industries such as automotive, aerospace, electronics, and general manufacturing can greatly benefit from CMT technology. The process is ideal for applications requiring high precision, minimal thermal distortion, and strong, clean welds.

5. How does SourcifyChina ensure the quality of CMT welds?

SourcifyChina employs a comprehensive quality assurance process that includes initial material inspection, in-process monitoring, and final weld inspection. Our experienced team uses advanced equipment and software to ensure every weld meets strict quality criteria.

6. Can SourcifyChina handle custom CMT projects?

Absolutely. SourcifyChina prides itself on its capacity for customized projects. We work closely with clients to understand their specific needs and deliver tailored solutions that meet their exact specifications and project requirements.

7. What is the lead time for CMT projects?

Lead time varies depending on project complexity and volume. However, SourcifyChina is committed to delivering timely solutions. We aim to provide accurate timelines during the quotation and planning stages, ensuring that your project remains on schedule.

8. How can I get a quote for CMT work from SourcifyChina?

To get a quote, please contact our sales team through our website or email with details of your project requirements. Our team will review your specifications and provide a detailed quote promptly.

Cold Metal Transfer (CMT) is a highly advanced welding technology that is revolutionizing metal manufacturing. Developed by Fronius International, this process is characterized by its low heat input and precise control, making it ideal for joining thin and dissimilar metals with minimal distortion and spatter.

– Low Heat Input: CMT operates at lower temperatures compared to traditional welding methods, which reduces thermal distortion and minimizes the risk of warping.

– Controlled Process: The system automatically adjusts the current and voltage, ensuring a stable arc and consistent weld quality.

– Reduced Spatter: The reduced heat and controlled droplet transfer significantly lower spatter, resulting in cleaner welds and reducing post-processing time.

– Thin Sheet Metals: Particularly beneficial for automotive, aerospace, and electronics industries where precision is crucial.

– Dissimilar Metals: Effective in welding different types of metals like aluminum to steel without defects, broadening its application scope.

– Precision and Quality: Employs CMT to produce high-quality welds with exceptional accuracy, crucial for industries requiring stringent standards.

– Cost-Efficiency: Reduced need for rework and post-processing leads to overall cost savings.

– Innovative Capabilities: Constantly upgrading its technology to maintain a competitive edge, ensuring that products meet global quality benchmarks.

By integrating CMT technology, SourcifyChina factory enhances its manufacturing capabilities, offering superior welding solutions that meet various industrial needs. If precision, minimal material distortion, and welding quality are priorities for your production requirements, SourcifyChina’s use of CMT positions them as a valuable partner.

Sure, here are some frequently asked questions (FAQ) with answers about sourcing Cold Metal Transfer (CMT) from SourcifyChina Factory:

Q: What is Cold Metal Transfer (CMT)?

A: Cold Metal Transfer (CMT) is an advanced welding technology that offers greater control over the welding process compared to traditional methods. It reduces heat input during welding, minimizing distortion and burns, ideal for thin materials and dissimilar metals.

Q: Why should I source CMT from SourcifyChina Factory?

A: SourcifyChina Factory offers high-quality CMT products and services with competitive pricing. Their advanced manufacturing facilities and experienced team ensure consistent quality and timely delivery.

Q: What materials can be welded using CMT?

A: CMT is versatile and can weld a variety of materials, including stainless steel, carbon steel, aluminum, and even combinations of different metals.

Q: Is CMT suitable for my specific application?

A: CMT is ideal for applications requiring precision, reduced spatter, and less heat-affected zones. It’s widely used in automotive, aerospace, and electronics industries. You can discuss your specific requirements with SourcifyChina for customized solutions.

Q: What are the advantages of CMT over traditional welding methods?

A: CMT offers several benefits, including reduced heat input, minimized distortion, better gap-bridging capabilities, and enhanced weld quality. It’s particularly effective for thin or heat-sensitive materials.

Q: How can I ensure the quality of CMT products from SourcifyChina?

A: SourcifyChina Factory maintains strict quality control measures, including thorough testing and inspections at various production stages. They also provide quality certifications and can accommodate additional third-party inspections if required.

Q: What is the lead time for sourcing CMT products?

A: Lead time depends on the specific product and quantity. SourcifyChina Factory strives for prompt delivery and will work with you to meet your timeline requirements.

Q: Can I visit the SourcifyChina Factory to see the CMT process in action?

A: Yes, factory visits can be arranged. Contact SourcifyChina to schedule a tour and see their operations and quality assurance processes firsthand.

When sourcing information on “Cold Metal Transfer” (CMT) from SourcifyChina factory, consider the following tips to ensure comprehensive and accurate details:

1. Understand CMT:

– Cold Metal Transfer is a modified MIG welding technique that focuses on lower heat input, resulting in less spatter and distortion. Its primary benefit is enhancing the quality of welds on thin materials and dissimilar metals.

2. Direct Communication:

– Contact SourcifyChina directly through their official website or customer service channels. Ask specific questions about their CMT capabilities, machinery, and applications.

3. Check Technical Specifications:

– Request detailed technical data sheets and case studies on their CMT process. Information about the type of metals they work with, welding speed, quality control measures, and previous project examples are essential.

4. Certifications and Standards:

– Inquire about compliance with international welding standards (e.g., ISO, AWS) to ensure high-quality and reliable processes.

5. Supply Chain Transparency:

– Understand their supply chain process to gauge reliability. Ask about lead times, raw material sources, and contingency plans.

6. Client Testimonials and Case Studies:

– Look for testimonials from other clients who have utilized their CMT services. Case studies can provide insight into their practical application, efficiency, and reliability.

7. Factory Visits and Virtual Tours:

– If possible, arrange a site visit to SourcifyChina’s factory or request a virtual tour to see their operations firsthand. This helps verify their capabilities and machinery.

8. Compare with Competitors:

– Compare SourcifyChina’s offerings with other factories to ensure you are getting the best combination of quality, cost, and service.

By following these steps, you can effectively source comprehensive and reliable information about Cold Metal Transfer from SourcifyChina factory.

If you require packaging machine for your product, SourcifyChina should be your primary option. Please send us your detailed specifications and obtain an immediate quotation.

Copyright © 2024 SourcifyChina All Rights Reserved.