Technology and Applications of wood cnc lathe

A wood CNC lathe is a precision tool used in woodworking to automate the process of turning wood into intricate shapes and designs. These machines use Computer Numerical Control (CNC) technology to guide cutting tools with high accuracy, enhancing efficiency and consistency compared to manual methods.

Technology:

1. CNC System: At the core of a wood CNC lathe is the CNC system, which interprets digital designs from CAD (Computer-Aided Design) files and converts them into precise movements.

2. Stepper/Servo Motors: These motors drive the lathe’s components, ensuring smooth and accurate motion.

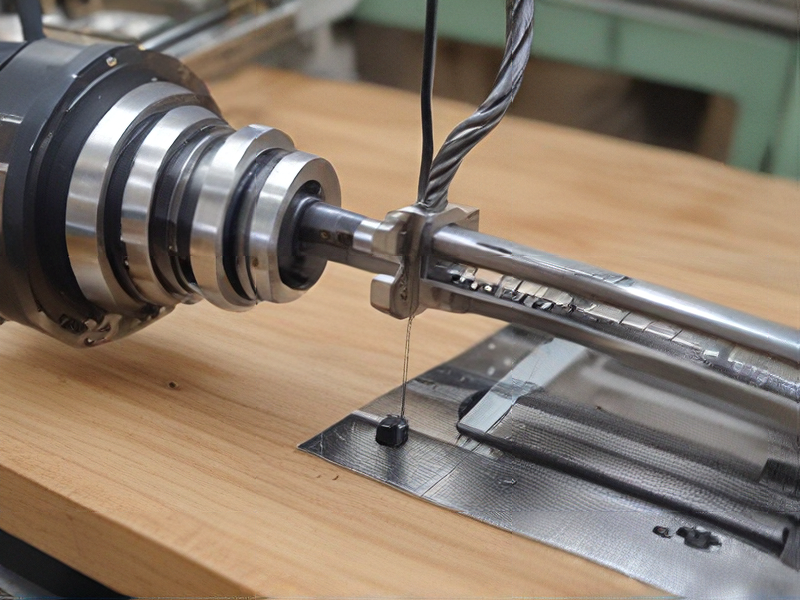

3. Spindle: The spindle holds and rotates the wood piece. Variable speed control allows for different types of wood and complexity of designs.

4. Cutting Tools: Interchangeable tools perform various operations like cutting, sanding, and drilling.

5. Software Integration: CNC lathes use sophisticated software for design, simulation, and execution, allowing for complex and precise designs.

Applications:

1. Furniture Making: CNC lathes create consistent and intricate patterns on furniture legs, spindles, and decorative pieces.

2. Artistic Woodworking: Artists use CNC lathes to produce detailed sculptures and art pieces with precision that would be challenging manually.

3. Mass Production: Industries benefit from the ability to replicate designs accurately and efficiently, making CNC lathes ideal for large-scale production.

4. Prototyping: Woodworkers and designers can quickly prototype and iterate designs, speeding up the development process.

5. Custom Woodwork: CNC lathes allow for personalized designs, making them popular in custom woodworking shops.

The use of wood CNC lathes has revolutionized woodworking by combining traditional craftsmanship with modern technology, leading to higher productivity, precision, and versatility in wood crafting.

Quality Testing Methods for wood cnc lathe and how to control quality

Quality testing methods for wood CNC lathes are crucial for ensuring precision, durability, and overall performance. Here are some key methods and controls for quality testing:

1. Visual Inspection

– Surface Finish: Check for smoothness and absence of defects.

– Dimensions: Verify that the wood pieces match specified dimensions using calipers or micrometers.

– Uniformity: Ensure consistency in shape and size across multiple pieces.

2. Dimensional Accuracy

– Precision Measurement Tools: Use calipers, micrometers, and coordinate measuring machines (CMM) to check dimensions.

– Tolerance Verification: Compare measurements against specified tolerances to ensure compliance.

3. Material Testing

– Moisture Content: Use moisture meters to ensure the wood’s moisture content is within acceptable limits.

– Hardness and Strength: Conduct tests like Janka hardness and bending strength to verify material properties.

4. Operational Testing

– Machine Calibration: Regularly calibrate the CNC lathe to maintain accuracy.

– Trial Runs: Perform trial runs and test cuts to ensure the machine is producing accurate results.

5. Surface Finish Testing

– Roughness Measurement: Use surface roughness testers to measure the finish quality of the wood.

– Visual and Tactile Checks: Inspect visually and feel the surface for any imperfections.

6. Load and Stress Testing

– Load Bearing Tests: Test the finished products under load to ensure they can withstand the intended stress.

– Durability Tests: Simulate real-world conditions to check the longevity and durability of the product.

Quality Control Measures

– Standard Operating Procedures (SOPs): Establish and follow SOPs for every stage of the production process.

– Regular Audits: Conduct regular audits of the production process and equipment.

– Training and Skill Development: Ensure that operators are well-trained and skilled.

– Quality Management Systems (QMS): Implement systems like ISO 9001 to maintain consistent quality standards.

– Feedback Loops: Incorporate feedback from customers and continuous improvement initiatives.

By integrating these testing methods and controls, wood CNC lathe operations can maintain high standards of quality, ensuring reliable and precise products.

Tips for Procurement and Considerations when Purchasing from wood cnc lathe

When procuring a wood CNC lathe, consider the following tips to ensure a smart and effective purchase:

1. Assess Needs and Budget:

– Determine the specific applications (e.g., furniture, intricate designs).

– Set a budget that includes the machine, software, and potential maintenance.

2. Machine Specifications:

– Size and Capacity: Ensure the lathe can handle the maximum dimensions of your workpieces.

– Spindle Speed: Look for adjustable speeds to accommodate different types of wood.

– Axes and Precision: More axes provide greater flexibility. Ensure high precision for detailed work.

3. Software Compatibility:

– Choose a lathe that is compatible with common CAD/CAM software.

– Verify that the software supports the file formats you use.

4. Build Quality and Durability:

– Opt for machines made from robust materials to ensure longevity.

– Check for features that enhance stability and reduce vibrations.

5. Ease of Use and Training:

– Prefer models with user-friendly interfaces.

– Consider the availability of training and support from the manufacturer.

6. Maintenance and Support:

– Investigate the ease of maintenance and availability of spare parts.

– Ensure the manufacturer offers reliable customer service and technical support.

7. Reviews and Reputation:

– Research user reviews and industry reputation.

– Contact existing users for their firsthand experiences.

8. Safety Features:

– Ensure the lathe includes essential safety features like emergency stops and protective guards.

9. Energy Efficiency:

– Consider the machine’s energy consumption, especially for large-scale operations.

10. Warranty and Return Policy:

– Check the warranty period and what it covers.

– Understand the return policy in case the machine doesn’t meet expectations.

By carefully evaluating these factors, you can select a wood CNC lathe that meets your needs, fits your budget, and provides reliable performance.

FAQs on Sourcing and Manufacturing from wood cnc lathe in China

Certainly! Here are some FAQs regarding sourcing and manufacturing from wood CNC lathe in China:

1. What types of wood products can be made using a CNC lathe?

CNC lathes in China can produce a wide range of wood products including furniture components, decorative items, table legs, and custom wood turnings.

2. What are the advantages of sourcing from China for wood CNC machining?

China offers cost-effective manufacturing due to lower labor and production costs. They also have a robust supply chain for wood and CNC machining expertise.

3. How do I find a reliable manufacturer in China for wood CNC lathe products?

Research and verify potential suppliers thoroughly. Look for certifications, customer reviews, and visit their facilities if possible. Engage in clear communication and ask for samples to assess quality.

4. What are the typical lead times for manufacturing wood products using CNC lathes in China?

Lead times vary depending on the complexity and quantity of the order. Typically, they range from a few weeks to a couple of months.

5. Are there any challenges or risks associated with sourcing from China?

Potential challenges include language barriers, quality control issues, and intellectual property concerns. Working with reputable manufacturers and having clear contracts can mitigate these risks.

6. What should I consider when negotiating pricing with Chinese manufacturers?

Factors to consider include product specifications, order quantity, payment terms, and any additional services required (e.g., packaging, shipping).

7. How can I ensure the quality of wood CNC lathe products from China?

Implement rigorous quality control measures throughout the manufacturing process. Conduct inspections at key stages and specify quality standards in your contract.

8. What are the logistics and shipping options for products manufactured in China?

Chinese manufacturers often have established logistics networks. Choose between sea freight, air freight, or courier services based on cost, urgency, and volume.

By addressing these FAQs, you can navigate the process of sourcing and manufacturing wood CNC lathe products from China more effectively.